-

Posts

954 -

Joined

-

Last visited

-

Days Won

6

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by soth122003

-

If I am correct, the amp gage does NOT go to ground. To check amperage it is done inline, in other words pull the hot wire and connect lead to bat and lead to wire to check amps. All the amp gage does is show current draw or positive charge. So connect gage to ign switch, light switch, horn relay and voltage regulator. If you connect to ground you might ground out a system or something. Could some one else verify my assumption? Joe Lee

-

Crud built up in the block. Your distribution tube. Timing could be off. Could be the gage itself (not likely though). Try flushing the block then reset or check your timing. Use a digital thermometer from Harbor Freight to check for hot spots on your engine. When you flush the block pull the drain cock from the engine and use a pick to clear it. Joe Lee

-

-

Glad you got it figured out. I was close. Not wired backwards, just incorrectly. I was in your neck of the woods last week. Went to Florence Al. to visit my dad for a few days. If it wasn't for all the rain, I woulda popped bye for a visit since your only about 2-3 hours from him.( After calling to make sure it was all right of course.) Joe Lee

-

If your getting 12v to the runtz, then check ign at the gage for 6v or so. if it's not there, runtz is bad, or it is one way and you have it backwards. Joe Lee

-

Hey Labrauer, If you took out anything that looked like a cup, it wont build pressure very well. In Keithb7 second post the valve is what comes out. Also if it is under pressure check the rod adjustment. The piston cup should be centered between the two holes in the bottom of the MC. One is a service port to supply fluid and the other small, small, small hole is the return port. (Relieves the pressure from the bakes back into the MC reservoir)Also most MC's have a breather hole in the side of the MC cap. Watch the vid it gives a really good explanation of the MC system. Joe Lee

-

Not the tranny. All the clutch does is disengage the clutch and pressure plates from the tranny. My guess is throw out bearing. When they first start going bad you will have a rasping or rattling noise as they lightly ride against the plate spring arms. When you press the clutch pedal down it puts a lot of pressure on the bearing and can make the noise disappear. When the bearing is shot though it squeals like a stuck pig. It might also be a clutch pressure plate chattering. Easy way to tell is adjust the clutch rod in, to take the bearing off the spring arm (it should be off by a 1/16" anyway) and if the noise goes away it's the bearing. If not I'd say it's the pressure plate. Now this is for just a straight tranny with no fluid drive but I still believe this to be your problem. Just a couple of wrenches and 5 minutes will tell. Joe Lee

-

Do a google search of wheel beauty rings and you'll get an idea. They are still pretty popular across all makes and models not just mopars. Now if they are original try ebay for pricing options. Joe Lee

-

Fuel Mixture Screw doesn't change the idle.

soth122003 replied to 48ply1stcar's topic in P15-D24 Forum

This will help out. The large ball is the discharge check ball and the small one is the intake check ball. The small one goes under the accelerator pump and stops gas from being pushed back into the float bowl and large one goes in the hole next it and has the brass screw plug over it to let fuel flow thru and keep it from being sucked back into the pump chamber when the accelerator pump retracts. Joe Lee -

Bought me an electric fuel pump about 5-6 months ago and put it in yesterday. Worked once and then poof. Man talk about pi**ed off. It was a Chinese pump so I got what I paid for. Will order an airtex here before to long, since people have had good luck with those. Joe Lee

-

Check the crankcase. It might be passing a seal in the fuel pump and going there. Might WOOOF if it is. Joe Lee

-

Yes. Connect the neg to the starter and the pos to the engine block. I would make sure that 1. the cables are long enough and 2. That the Jump box has switch to turn it on and off. Have done this many times on mine with no trouble. Joe Lee

-

No restistance at the brake pedal: Master cylinder worn?

soth122003 replied to 50s-coronet's topic in P15-D24 Forum

Agreed. Check the wheel cylinder and lines first. Just replaced a wheel cylinder on mine yesterday. As far as the MC goes the special tool is for bench bleeding and it makes life easier when bleeding the whole system. When I do an MC I pull it apart hone the cylinder wall and when I put it back together, put the MC in a vice, cap the ports and fill with fluid. Then using short 1-2 inch strokes on the pedal lightly pump the MC till no air is coming out in the reservoir. This gets rid of 99% of the air and the rest will bleed out with the main bleed of the system. This vid should help with a lot of your questions. Joe Lee -

-

Hey Brandon Welcome to the forum. In this pic look at the center piece. It is the speedo. At the center is a post looking piece pointing to 1'oclock. This is the lube point (using a lite weight oil 3in1, liquid wrench or so) in side is a felt wad which soaks up the oil and lubes the speedo. It just takes a few drops. Joe Lee

-

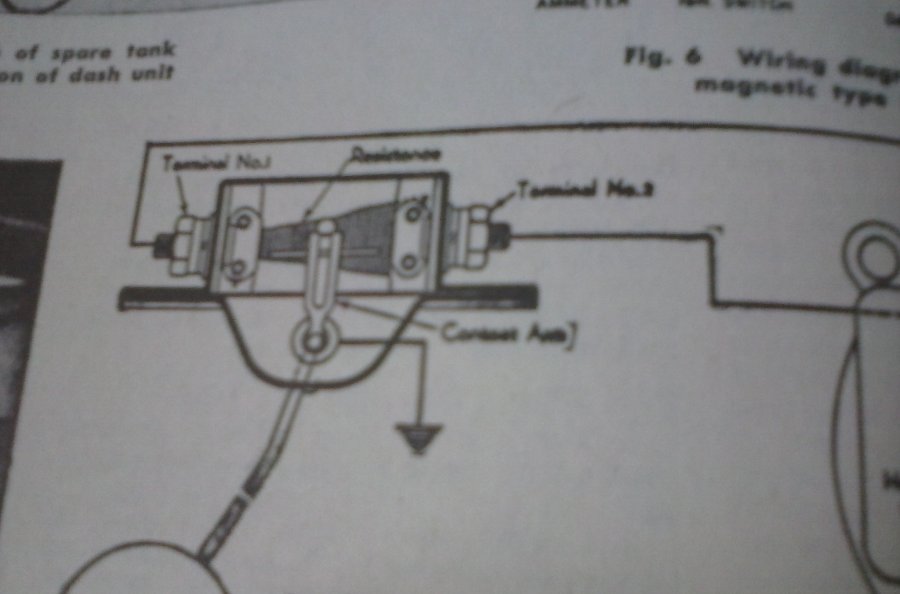

Not a problem Cold. I remember how frustrated I was trying to look at a darkened diagram and since buying the motors manual and with the ageing eyesight, a set of magnifying lenses works wonders. Joe Lee

-

Hey Cold, Pull the gage out and check for any obvious damage. I believe the needle should free float. Then check the contact points on the gage for sticking. Clean with a points file or emery cloth. The picture in the Plymouth manual sucks so here is one from the Motors manual. Sorry for the focus on the sender pic, but it is mostly self explanatory. Also I would spray the whole thing with contact cleaner to get the crud off if any is on there. Joe Lee

-

In addition to what Pymouthy said, Do you have the head off? If so measure the wall thickness between the pistons. Since they used common sense back then, logic says that this is the thickness of the piston wall all the way around the piston. Then subtract the pit size from the wall thickness and that should give you more info on what to do about the pit. Like was said earlier, the cooling system is not pressurized, and if the pit is lower than the rings and compression area you will probably be good to go with a good cleaning and sealing of the pit area. Joe Lee

-

Thanks D, Mine is the 1 1/8". But for 89 bucks I'll take a chance on the Cardone when the time comes. Joe Lee

-

I was looking at a few different wheel cylinders for my 48 P-15 special deluxe and I thought about my MC. I looked around and saw the prices at amazon and rock auto. Then I found I sight I hadn't seen before. The MC's there were half the price and made in the USA. The problem was they say they won't fit my P-15. They will however fit a Dodge, DeSoto and Crystler's from the same year 46-48. I didn't think the MC's were different on those models. The sight is Cardone http://www.cardone.com/find-parts I hit up Andy B's site and they show the same MC for all that year except those with power brakes. The MC looks the same,so I wondering if the dimensional specs are different. Any one have a reason or know what the difference is? Joe Lee

-

1950 Plymouth Special Deluxe Coupe Purchase / Updates

soth122003 replied to dhrandy's topic in P15-D24 Forum

Welcome to the forum. Nice looking car and with your to do list, it is not that much in the scheme of things. Try an S.O.S. pad on the bumpers to remove the rust. Joe Lee -

Hey Cold Blue, Connect the wires before putting the sender in the tank. Put the float to down or empty and check the gage. If it reads other than empty reverse the wires and check again. Or put the float to full and check. Either way it is an easy fix. Then mark the terminals on the sender put it in the tank and hook it up. Joe Lee

-

Hey Cold Blue, Connect the wires before putting the sender in the tank. Put the float to down or empty and check the gage. If it reads other than empty reverse the wires and check again. Or put the float to full and check. Either way it is an easy fix. Then mark the terminals on the sender put it in the tank and hook it up. Joe Lee

-

Kahunah is right. Float points to the left or filler hose on the tank. Joe Lee