joecoozie

-

Posts

379 -

Joined

-

Last visited

-

Days Won

6

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Posts posted by joecoozie

-

-

Joe,

Glad I was able to help

-

1

1

-

-

1 hour ago, Plymouthy Adams said:

chrysler dodge and desoto are the big three...plymouth is a smaller vehicle...body panels are not going to interchange....

So will a Chrysler trunk lid work?

-

1

1

-

-

Questions:

Would a trunk lid from a 46-48 Plymouth interchange with this one?

What about one from a 46-48 Chrysler?

-

1

1

-

-

Sent you a PM (Private Message)

-

1

1

-

-

Just an experience I had once and not saying this is the OP's issue:

Tried to move a friends 50's Cadillac out of the garage and the car would start (cold) and idle all day. But when it got warmed up, every time we tried to move it (in gear) it would stall out. We primed the carb and it would start and idle fine. As soon as it was put into gear to be moved it would stall. After a couple of hours of doing this and that it turned out to be a bad coil.

-

I don't see a heat shield over the fuel pump which can cause what Sam Buchanan explained. -

Other issue MIGHT be the coil is going bad.

-

Sent you a PM

-

Sent you a PM

-

1

1

-

-

Sent you a PM

-

20 minutes ago, GTfastbacker said:

Hammer the motor for an hour. no success

Sorry to hear that.

I wish it could have been a simple fix.

-

1

1

-

-

This is a long shot but worth a try and I may get laughed at but......... while you have the power on to the wiper motor try to tap it with a handle of a hammer.

Maybe it's just hung up.

Also, try to move the arm linkages. They can get hung up, too.

-

1

1

-

-

-

Soft rubber mallet, yes

-

1

1

-

-

I couldn't tell you exactly what I used but I think it was 3M Adhesive.

It accomplishes both tasks of holding the cap centered AND holding it tight against the cap so when the edge(s) are peaned you get a good,snug fit - which would prove to be a difficult task without adhesive unless you made some kind of a press to pean the edges - similar to what the factory did.

-

2

2

-

-

I did replace the skins on my hubcaps several years ago.

What I did was remove the old skin by prying the "lip" up.

Then I sandblasted the metal hubcap to get a nice smooth surface - then I primed them to prevent rust.

I then installed the new "skins" (which I believe were $40.00 each) by using a strong adhesive which I let dry - then I peaned the edge to wrap around the cap.

I have yet to install the "new" hubcaps on my car - they are still in the box.

I know $100.00 each is a lot of money BUT....if you rechromed yours it would probably be about the same cost (or more???) BUT...then you have to paint the CHRYSLER script lettering - which never seems to look good.

It isn't very difficult but it is time consuming. Centering the skin is probably the most difficult part of the process.

-

1

1

-

-

-

You can remove the entire front floor pan and do it from the top (inside the car).

-

1

1

-

-

-

21 minutes ago, ktb said:

Can anyone tell me the width and length of a 1951 Dodge B-3-B pickup? I believe it's a 108" wheelbase short bed. I'm planning to trailer one across the country next summer and want to make sure I find the right size trailer. Thank you!

Try posting your question here:

-

2nd:

Anyone knows the use for these round socket?

Speaker connection?

-

1

1

-

-

That is the Sisson choke for the carb.

It looks like it is disconnected (electrically)

-

1

1

-

1

1

-

-

40 minutes ago, rcl700 said:

I'm attempting to pull the trans on my 48' I saw a video that Kieth posted where he made guide pins by getting log bolts and cutting the head off. I attempted this but I'm having trouble with the top left bolt threading in. The angle the bolt needs to be seems to be blocked by the shift casting. Has a anyone done this on one these transmission types?

Am I missing something?

Any and all help appreciated. Do I need the pins?

I'm just learning ?

Is that a crack in the bellhousing where the threaded hole is for that bolt or is it just grease/dirt buildup?

Also, after you cut the bolt (like Sniper said), you may need to jack up the transmission (slightly) in order to get the bolt and the hole lined up.

-

This one is a bit clearer

-

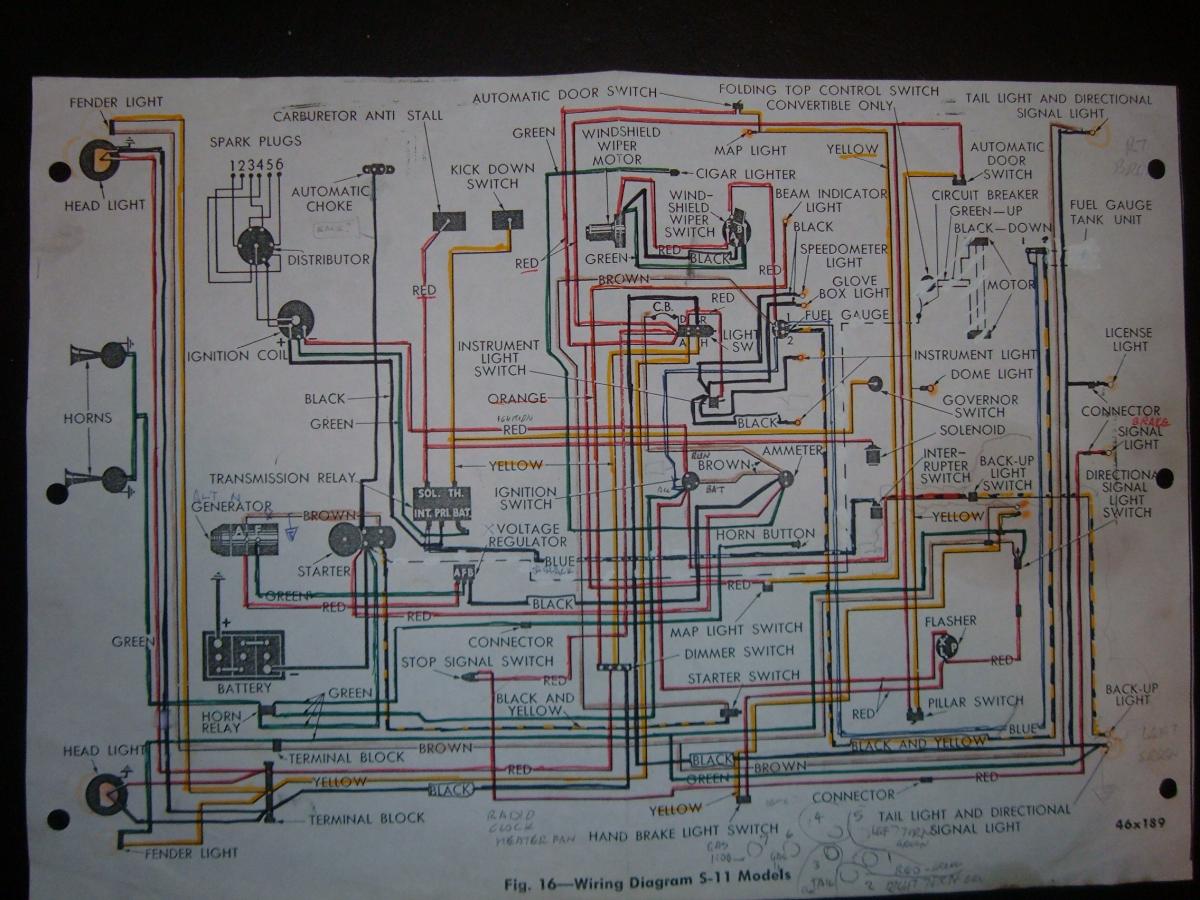

Here's the wiring diagram if anyone wants to look at it.

-

1

1

-

Will 1951 DeSoto car A arms bolt up to my 1940 Plymouth Coupe?

in P15-D24 Forum

Posted

Will a-arms from a 46-48 Chrysler (6 cylinder car) work/fit???

Sent you a PM