-

Posts

18 -

Joined

-

Last visited

Reputation

4 NeutralProfile Information

-

My Project Cars

1937 Dodge Fargo, two and a half ton flatbed truck with a 1956 Plymouth engine in it

Converted

-

Location

Tasmania Australia

-

Interests

To many to list

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

-

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

Got around to dooing some more work on the ol' truck. Decided to hacksaw off the manifold studs to get the manifold off. Managed to remove what was left of them with a pair of vice grips. Removed the front starbord (Drivers side) wheel for easy access to the valves and have started the long job of making the mating surfaces shiny. Laplaplaplaplap. -

Forgive my electronic ignorance (I studied it as part of a tafe course 20 yrs ago) but couldn't you use a buck converter to create a -6v terminal and then plug that into the radio's -ve input creating a 6v potential difference with a positive earth?

-

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

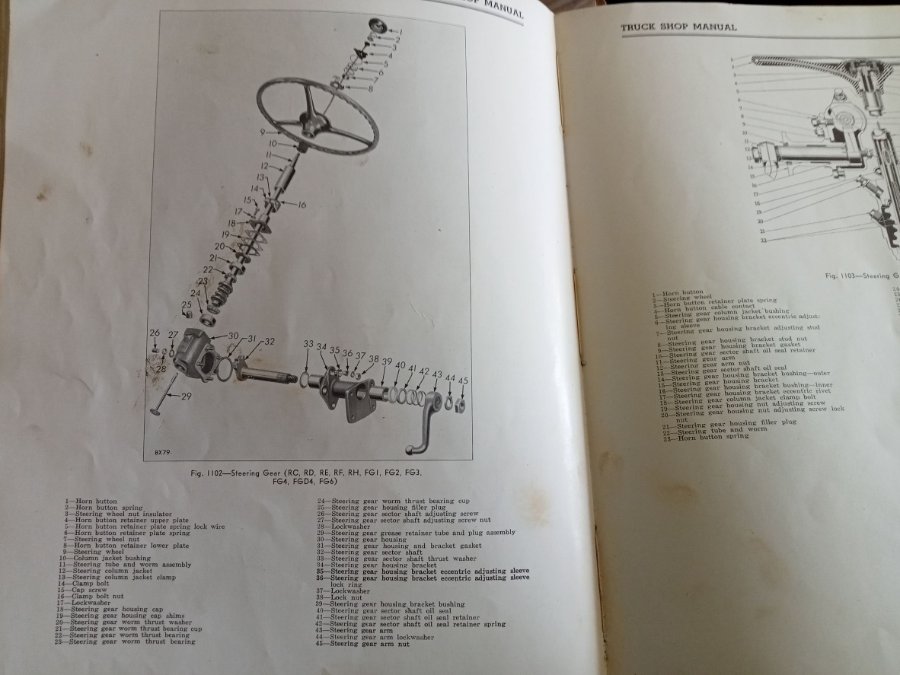

Thank you keithb7 for this YT vid, helped me visulise the exploded parts diagram In my manual. I need to flip it all (RHD) but feel OK about that atm, ask me again after a day of skinned knuckles and head scratching. -

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

Any advice on moving the steering column out of the way? do I need a pitman puller? It all seems like a lot of work just to get at the valves? -

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

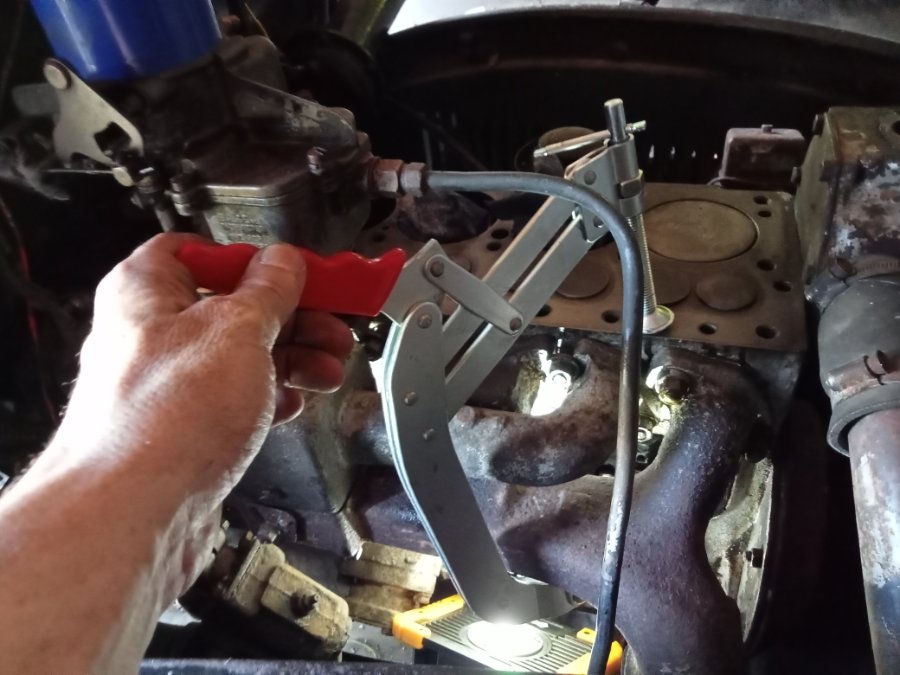

Soo after perchacing a 9/16 socket from the local tip shop and giving it a once over with the angle grinder I managed to make a tool capable of removing the offending bolt. Unfortunatly it took me another hour or so to get one of the washers off as it was threded onto the stud and hard to get a grip as it was the one closest to the firewall. After taking all the manifold nuts (and the two bolts) off I ran into another problem, the manifold won't clear the steering column... The last photo is all the nuts and bolts off of the manifold minus the one that rolled off somewhere (I'll thoroughly search for it tommorow) -

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

Oh and my service manuel for the truck seems to be missing the torques for the manifold. It's got a section titled Fuel and Exhaust and then has a few pages on the Carby and nothing on the exhause. Anyhow when I get to putting It back on, how much torque do I apply. I think I read somwhere here 25ft lb but I'm unable to find it right now. Also in what sequence, I'd assume from centre out for tightening. -

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

Soo having looked at the valve seats I'd like to at least lap them / deffinitly inspect them. Unfortunatly this valve commpression tool doesn't fit with the manifold on so off it goes (photo for scale I'll stick a block of wood on the bock so as to not damage the mating surfaces when i get to that point). All the manifold bolts i got to (12 of the 13) were very easy to get off, even the sneaky one in the centre, probably under torque. Unfortunatly one bolt i was unable to get a socket on to as the exhaust manifold is in the way of the socket fitting over the nut, It didn't help that the steering column was in the way (i guess this would be easyer if it wasn't RHD) ... Upon further inspection I realised If I could remove the exhaust manifold seperatly I could get acess to the said bold (3rd from the back). Upon further further inspection I noticed one of the four bolts holding the manifolds together was already missing. So against my better judgment and on a 33deg day (91 in f, hot for thease parts) I tryed removing the other 3 bolts and managind to break another one (i now realise that the 'missing' bolt is also broken off and still holding the manifolds together) and was totally ineffectual with regard to the other two. So I'm left wondering how they got it on in the first place and how to remove. Did they put the intake manifold on first or did they just have vastly thinner walled sockets than I??? I'm thinking the solution might be to get a cheap socket and remove a third of it with an angle grinder so it fits over the nut and then little by little remove the nut, Or to purchace a set of crows foot wrenches (although I'm not entierly sure they will fit between the manifolds? Any suggestions greatly appreiciated... Oh and a final photo of the valve springs (I'm really keen to get in and cleen this but figure it will be a lot easyer once I get the manifolds removed) a -

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

Got the head back from the shop, they needed to take 18 thou off to get it flat so I'm glad I did. Now back to cleaning the block.. pics to follow -

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

Ok, so finally got back to working on the old truck. Removed the head and in the process found out that I didn't have a thermostat installed! -

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

-

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

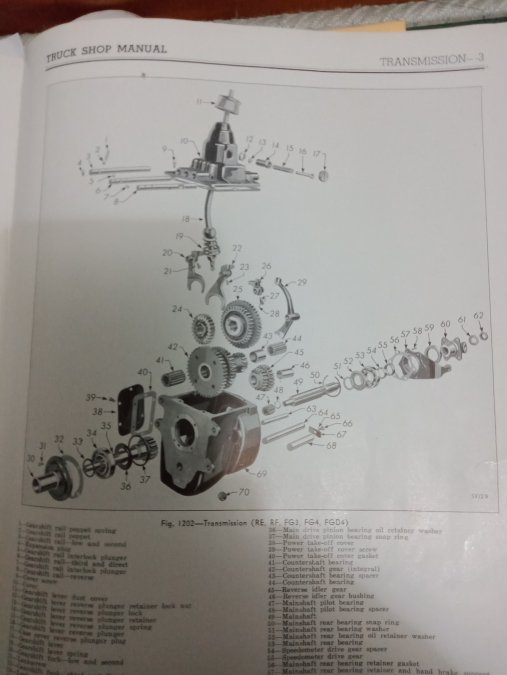

I'm going to pick up the new fan belt and the distributor cable kit tomorrow and was thinking I'd get some diff and tranny fluid while I'm at it, I'm assuming the type of diff fluid doesn't matter too much as long as it's quality hypoid stinky oil, but the transmission being so old and probably non synchromesh I'm wondering if it needs something special?... can anyone identify the gearbox? looks like the four speed from the RE, RF, FG3 FG4 and FGD4's (1937) from my service manual, which recommends "Mild Extreme Pressure Lubricant Summer-Temperature above 32deg F., S.A.E. no. 160 or S.A.E. no. 140" It has a serial number in the bottom right of the page 3X129, and has a P.T.O. cover that looks like the one in the above photo. can anyone recommend a modern equivalent? -

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

I also got the fuel tank out, it clunks, i believe the baffle is loose but I'm not sure, apparently their is a local guy who is an expert in folding steel so I'm going to see if he can open it up and fix it for me. The screws are pretty seized and their is another pair of holes in the top that will need filling in. -

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

Sooo, I got it to fire today, did away with the fuel lines because they were a bit (a lot) rusty so I went with the old tip some peddy (petrol) down the hole (after cleaning and filling the carburettor bowl). I've got a video of it turning over but you'll have to wait until I can get the vid off of a friends phone before I can post it firing. I went to check the compression but the kit I've got doesn't have the right thread for those spark plugs they were hard to find replacements also but I eventually found some that I have on order. I've taken out the fuel tank the fuel pump and the fuel line for replacement or overhaul. The points were corroded and the distributor Leeds were in poor shape so I'm going to replace some of the wiring too next time I get a chance to work on it. I took some photos of the gearbox, can anyone give me more information as to what it might be? Forget to track down the vin numbers, next time hopefully Friday.... I think the writing on the gearbox says c-3566 something though it's hard to read -

'37 Dodge Fargo restoration

Lukey Moonshine@ replied to Lukey Moonshine@'s topic in Mopar Flathead Truck Forum

Sorry about the stupid questions, have done some research and answered a few of them myself. Sooo, you can obviously check the valve clearances without removing the intake and or exhaust manifolds as they should be set hot, I'm going to check them cold and aim for I/E of 10/13 thou to get her started and then dial it in once the engine is hot (8/10 i believe), does that sound about right? It didn't have a battery and I'm having trouble finding a 6v starter battery so it looks like I'll need to wait until Tuesday (Monday is one of our queens many Birthdays, why we don't send her packing and become a republic is beyond me)