-

Posts

1,739 -

Joined

-

Last visited

-

Days Won

9

Cpt.Fred last won the day on September 19 2017

Cpt.Fred had the most liked content!

Reputation

183 ExcellentContact Methods

-

Website URL

http://www.meanwhile-at-the-laboratory.blogspot.de

Profile Information

-

Location

Berlin, GER

-

My Project Cars

1940 P10 2door sedan

Converted

-

Location

Berlin, Germany

-

Interests

wrenching

Recent Profile Visitors

3,001 profile views

-

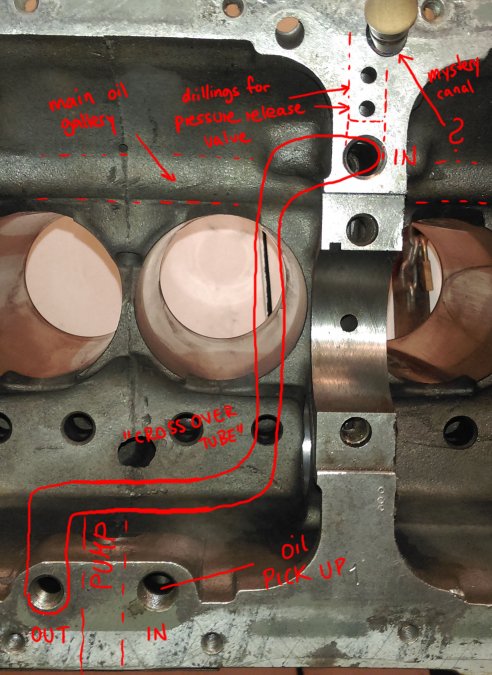

that helps a lot, actually. i always keep forgetting that the imperial club has all these neat little books online, they're absolutely great! from what i see here the answer to my question lies on page 14 of that book: the mystery passage i was wondering about must be the dry run prevention sytem. thanks, Don! ?

-

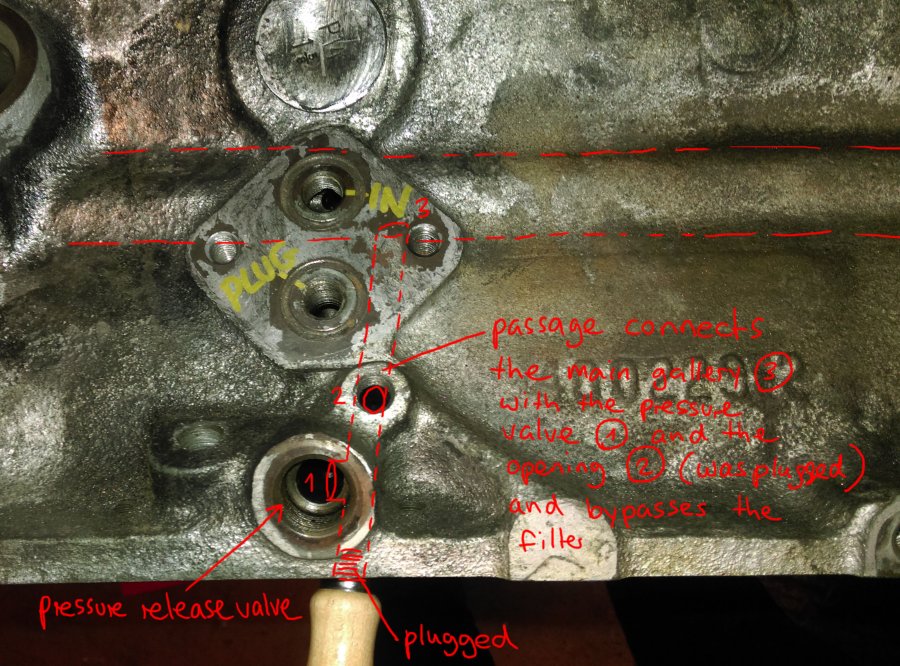

does anyone have an oil flow chart for these full flow long block engines? i recently noticed that there is a passage connecting the pressure release valve canal directly to the main oil gallery. that would mean there is a chance for unfiltered oil to get into the bearings, bypassing the filter, although that pipe plug is installed. i'd love to know why it is there and how exactly the factory intended the pressure release piston to work. the whole thing is different from the short blocks. sorry for hijacking this...

-

very cool, my fingers are crossed it runs as good as it looks!

-

nice piece. i'm using the AFR gauge from Innovate Motorsports

-

i will look into that. my experience is they move upwards pretty quickly once the butterflies open. by the way, you have to post a video of the car driving by and some more outside views of it

-

thank you Jim, great info once again. i really had hoped for a place to buy these parts new and in logical order from lean to rich, but i guess that would be too easy...? i was running 159-59S mains in my triple carb setup on the 265. these were too lean at cruise. 159-61S were better, 14-14.5 AFR. the engine was drowning in fuel above 3000rpm and under heavy load in overdrive, i experienced 10,5-11 AFR, intolerable. i tried two sorts of step up jets, 149-113S (leaned out the cruise too much and still flooded under load) and 149- 43S (too much in general)... i can see the logic behind the numbers on the main jets, but the ones on the step ups don't quite add up for me. funny thing was that somehow the test results were not exactly what i had expected, especially changing the step ups had far bigger effects over the whole rpm range than i had thought before. good to know your measurements now, i will check the orifice diameters and then try soldering and drilling as well. another thing i did on my first triple setup on the old 201 was putting weaker springs into the step up jet assembly, allowing it to stay shut just a little longer. on the smaller engine that gave me pretty good results and the AFR was in an acceptable range. thanks for taking the time and sharing all your measurements! Fred

-

Jim, good job as always, i really love your car! speaking of jets, where do you get yours, and do you have a list that indicates which number jet is leaner or richer? i haven't found anything like that yet, and i would really like to see one. i always find it confusing to sort through the different mains and step ups and test drive them with the afr sensor, only to be confused again by their behaviour in the carb thanks, Fred

-

sorry, no spare crank here either. i'm going to call a few people and look around, though. watch ebay and classifieds closely, engines do turn up every once in a while, but getting pricey lately... best of luck to you! Fred

-

anyone running Lake pipes on their P 15 or d24

Cpt.Fred replied to thebelvedereman's topic in P15-D24 Forum

the car is air ride equipped -

it purrs! sweeeeeet ?

-

anyone running Lake pipes on their P 15 or d24

Cpt.Fred replied to thebelvedereman's topic in P15-D24 Forum

a friend of mine recently built this. if you decide to use lake pipes, it's imperative to lower the car as much as possible to make it look good, imho. i think his car is gorgeous, but surely some might disagree. -

so cool! i had compression seeping out at the beginning, too, but going through a few heat cycles and carefully retorquing it when hot fixed that. i think i retorqued four times and it always gave in a little until it finally sat right.

-

Ha, nice picture there, Walt! that sure was a great day, i would have loved to have more time to chat with you, it was all a little too much to take in at once for me, i must admit. we went to dinner that evening and then back to George's the next day and said goodbye and talked some more, but unfortunately we had a tough schedule to get on our way to the east. i hope you had a good time at Carlisle! best, Fred

-

ha, cool idea. still, i hope you don't have to touch those fittings too often later on :)

-

i'm jealous of you blasting cabinet nice work on the oil return and carb!