-

Posts

1,612 -

Joined

-

Last visited

-

Days Won

13

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Everything posted by Bryan

-

-

Back from vacation. Removed Fluid Drive and timing/crank gears. Removed all manifold bolts but manifolds won't come off. Don't want to crack this one like the last. Think the Fluid Drive is toast. The clutch plate turning feels like it has gravel inside. Plate wobbles. Took the transmission out while car was in the woods. Thought I had the angle right pulling it out using transmission stand. Not sure. Given the condition of the motor no telling. FD might have already been like that.

-

Looks good. I've been trying to start work at 7 am and work to 10-11 am. A little cooler here though.

-

I would start with simpler, cheaper solutions first instead of changing the crank pulley and adding an electric fan. Maybe the multi-blade fan James D suggested or a different anti-freeze type. Try a shroud first?

-

Don't think spark plugs would start suddenly like that. More like Los said, check points. Maybe at night pop the hood and check if any sparking between the wires.

-

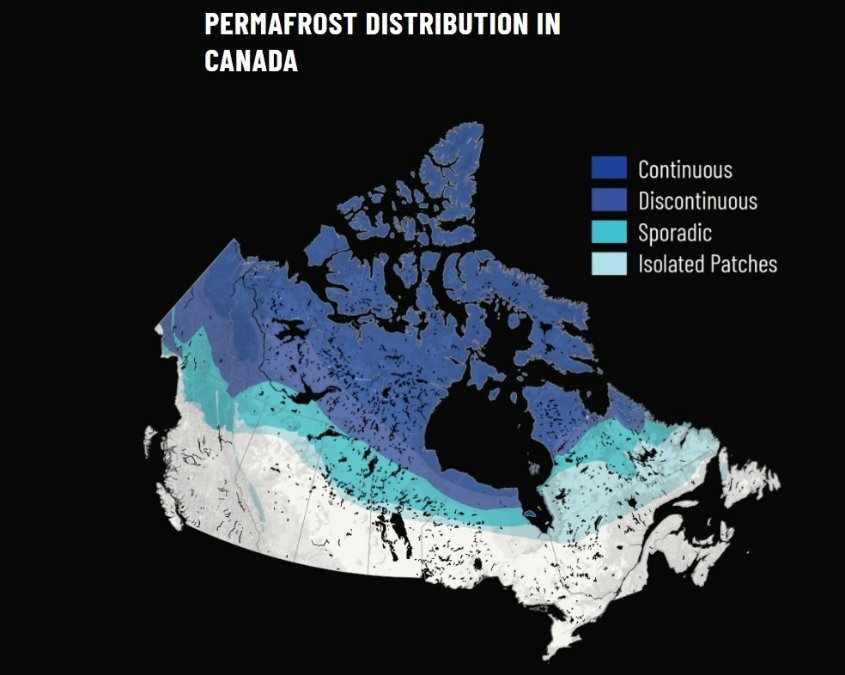

That's 1 1/8 for yous guys up there..??

-

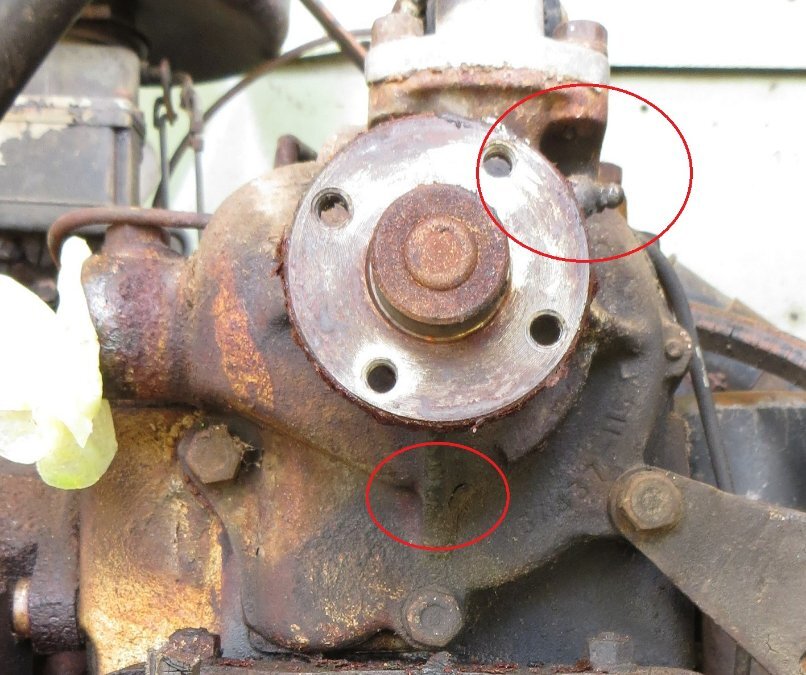

What is that little "weep hole" on the bottom of my water pump?

Bryan replied to MarcDeSoto's topic in P15-D24 Forum

Not at home for a while so I'll have to check next week. -

What is that little "weep hole" on the bottom of my water pump?

Bryan replied to MarcDeSoto's topic in P15-D24 Forum

The original was a 2 rotor type. I bought a new one but it has an extra hole on the back plate for the external bypass, which I don't have. Wasn't expensive. I'm going to use the original back plate, extra to me already blocking the hole off in the block. -

What is that little "weep hole" on the bottom of my water pump?

Bryan replied to MarcDeSoto's topic in P15-D24 Forum

-

What are these brass plugs on the left side of the block?

Bryan replied to MarcDeSoto's topic in P15-D24 Forum

-

If it cranks easily and there's no traffic, you could put it in neutral and cut the engine off and let it roll downhill going at speed. Then you know if it's a squeaky fan belt or something with the motor. Could test it with clutch pedal pressed and out also.

-

We're away for a while. When I get back I'll measure the journals. I think that one main is really ground down. Ridge is so high you can see it from 5 ft away. I'm going to start a motor parts warehouse. ?

-

Yep, was free. It was basically dry with about 3 small pin holes about 2" from the bottom of the sump. That main journal had a visible ridge in the middle. In the woods at my father's. At least I can have another spare block, a few extra rods, the vibration damper and pulley (which I needed), another head (now 3). You at least know why they parked it. My father towed it down for parts.

-

Reckon without a measurement yet it was a stupid question to ask...

-

I think y'all are dwelling on this too long.. ? ? I couldn't help myself.

-

Took a while getting the engine in out of the woods and into the garage. Oil pan had small hole and 3/4 to bottom on side. No liquid oil in pan, just heavy paste. I did a cursory look at the 3rd rod bearing and 2nd main. End of the day and wore out. No time to take it apart further. The 3rd rod bearing was shiny inside, but didn't see heavy rust, pitting, or scars. Was a clevite bearing shell, was wondering if the 001 was a size? Really worried about the main bearings. 2nd main journal has a visible ridge in the middle where the bearing shell groove was, which means both sides wore down a lot. Ridge looks bad. Bearing was really worn. Hard to see in that picture but it's easy to feel the ridge. It's not one of those, "catch it with your fingernail" you can feel the hump easily. I'm wondering if the crank for the engine I pulled is toast? Bryan

-

Got the motor in the garage. Had a slight mishap and rode the see saw. Didn't get hurt or damage anything. Also, oil pan had a small hole in it looks from rust. Pan was dry and caked inside, maybe most of it dried up. Going back out to look for any number on crank (if it was turned). Crank doesn't appear rusty, just caked in dried oil.

-

Got er' pulled. My older brother helped. Took a few tries to get the ramp under. Dug out behind the truck tires to make it lower. One arm of the hoist had to go below the car frame. Then had to jack the back of the truck up a little to make the rear of the trailer go down further. Used straps on the upper side of the hoist to keep it from rolling downhill in the trailer.

-

McMaster Carr has a bushing that would make it work. Might have to shorten it but hey, it'd be centered. spacers | McMaster-Carr

-

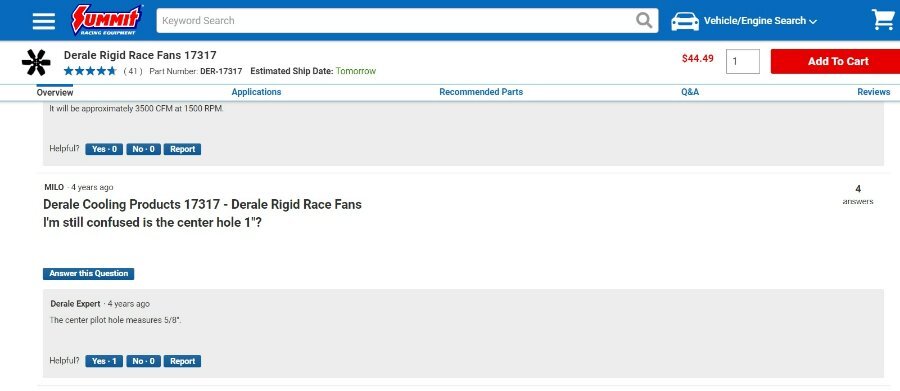

On the fan I just took off of the 48 Dodge sedan in the woods the center hole is 1 1/8" diameter and the blades were 18" end to end.

-

-

Took me a bit. Derale doesn't list it. Nor Amazon questions yet. Says 5/8". 2 other sources say same.. 1930-2010 All Makes All Models Parts | 17317 | 17 Derale Standard Rotation Steel Blade Rigid Race Fan | Classic Industries Derale 17" Rigid, Steel-Blade Race Fan - Belt Driven - 8,000 RPM Derale Radiator Fans D17317 (etrailer.com)

-

I saved the link. If I get mine running and try it out a few months to get the feel of it, might start then with improvements.

-

Mother in Law in or out? ?

-

I'm of the "let it go" crowd. If that thing gets to tipping over I'll be in the other direction. Amazing how many people will try to stop some extreme weight from going. Just like chain saw work..the butt end of that tree will sometimes kick backwards..always be to the side and have clear area to run.