Leaderboard

Popular Content

Showing content with the highest reputation since 01/19/2013 in all areas

-

Yesterday morning my wife and I left home and headed on a 300 km road trip to Osoyoos BC. My Chrysler was fantastic. OD was engaged on the hiway the whole way. Great cruising. Ambient air temps about 30 cel. The cooling system stayed between 170F, then up to 180F. T-stat would open then drop back to 170. The thermostat cycled and regulated perfectly. I did inatall a 6V electric aux pump incase needed. The whole trip was great. When we arrived in Osoyoos we got into some traffic. Stop and go. After 10 mins or so we got out of it. I hit the accelerator and she hic-cuped and sputtered a bit. I hit the switch on the electric pump, and it worked perfect. Just as I had hoped. 300 km back home tomorrow. Then I’ll post my fuel economy numbers. About and hour from departure I did advance my timing slightly. I could feel it. She got a little more jump in her step! A few picks of our area. Its been a great tour. More confidence building. More tours are to come!26 points

-

Pretty cool feeling after all that time, effort & money invested. I'd love to rebuild another engine soon , yet it's quite a pricey little hobby. All in, I estimate I spent about +/- $4500 USD to rebuild the engine myself, to stock condition. It was a 228 CI 1953 25”Canadian Dodge engine. I had it bored over to make it a stock 237 ci. The Desoto engine. The majority of my costs was the full machining. Oh and parts freight costs! Other than an align bore, everything else was machined. Crank, head, block/caps and con rods were re-used. Pretty much every other wearing part was new. New cam, tappets, guides, valves, springs, pistons & pins, piston bushings & clips, etc. I also had the generator rebuilt during the process. Water pump and new radiator rebuild were only about a year old so did not include these costs in the amount above. I gained a ton of experience and had a ton of fun. I was very pleased when the engine fired up immediately for the first time. It idled and ran well right from the first crank of the starter. My 1938 Plymouth has been a very fun and educational lab tool for me. I rebuilt my first transmission on it as well. Driving it between improvements and major repairs, has proven very rewarding and incentivizing. I recommend you give it some thought. Think about rebuilding your own engine. Of course you need clean dry shop space. Tools and some wits about you but it's not a difficult project. For those who follow me on You Tube, a video of the start up will be posted within a few days. Thanks to those who supported me here with my questions. This site has my back, so I feel a little more secure diving in to big projects. - Keith20 points

-

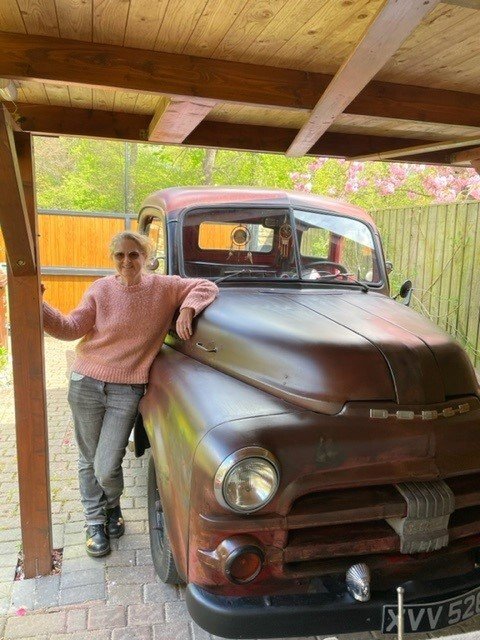

My 52 B3B. My grandfather bought it on October 21, 1952 for $1,634.81 to use at his auto repair business. He told me when I was about 10 that it would be mine one day and I inherited it in 1975 with just under 48,000 miles on it. Work, kids, life, I just got around to the restoration thanks to the pandemic lock down. My goal was to put it back just like it was the day he got it. That's him at his shop in the early 60s.20 points

-

How many here could look the other way when this opportunity presented itself? 1938 Chrysler Royal. Restored right down to the single last bolt, 25 years ago. 7,000 more miles on the odometer today, since it was appraised in 1998. Came with all the candy. I have receipts as far back to the original owner in 1959, when he installed a new engine. Been sitting indoors for 25 years, barely used. Has a 265 ci 25" engine in it. Gobs of torque. 3 speed manual with OD. Factory options include cab heater, clock, AM radio. Everything works like new as it should. It is so tight, and drives like a brand new car. He loaded up my 8 foot long truck box with spare parts too...Tons of spare parts! I left home at 4:15 am yesterday morning with a trailer. 4 hour drive each way. I was ready if the car was right, I'd take it home. I did. This is a fine automobile and I am extremely happy to own it. Sad too, to see the fellow invest so much, to let it all go 25 years later. The seller was a gentleman. A professional auto dealer mechanic his whole career. What a pleasure to deal with. I feel very fortunate to take this car and make it mine. More to come on my YT channel. My 1953 Chrysler is currently listed for sale locally.19 points

-

19 points

-

I just scored a new car I’ve wanted for a very long time. This car has 37,400 miles on it! It’s about as original as it could be too. One thing I am amazed about is it doesn’t wander at all. There are a few things I’d like to perfect but I am not going to go overboard. A paint job and minor body repair to prevent rust is the biggest item on my list. I’ve been driving every day and it starts and runs like a near new 49 Plymouth.18 points

-

Some of you are connected to me on Facebook, and have seen the pictures, but the back story I want to share here might be of interest. Last week I followed a lead that took me to a house about 19 miles northwest of me where I found another P15c Plymouth patiently waiting for resurrection. The car, a nice example of loving care over its 70 years of existence, is now in my garage and has become the second in my permanent collection. In the past 6 months I've bought two other P15's but that I was tempted to keep, but they've since taken a boat trip to Holland where my business partner will find decent homes for them. The newest acquisition is a convertible. I've yet to have the documentation pulled from the archive, but the car is believed to have been sold in Massachusetts originally. I am very anxious to see which dealer and to be able to see if the building still exists. The original owner was from Lexington Massachusetts, as shown on one of the 30 or so registration cards that came in the glove box. He was a Doctor of Physics and worked at a small institution known as the Massachusetts Institute of Technology, Lincoln Labs. Some may recognize the name of this establishment as being home of a small project code named "Manhattan". While unconfirmed as of yet, there is an endowment left in the owners name and I have written to enquire if this learned individual was indeed connected to Atomic research going on at the time. This gentlemen kept the car for many years, and I suspect the last year of ownership was 1964 which is documented in a Midas Muffler lifetime warrantee also delivered with the car. The glove box was filled with maps of the eastern seaboard and a list of antique shops in each state. Researching his name I found that this man and his wife amassed one of the countries largest collections of Shaker furniture, a portion of which was sold after his death and another portion donated to the Smithsonian in DC. Further research has shown me that the man died at the ripe age of 94, leaving a sizeable chunk of money to create an endowment that reports assets over $1mil today. The second owner of the car is another local gentlemen who owned the car from 1964/5 up until 2001. This gentleman is still alive and well and living in Concord Massachusetts. He started a small business in the 1960's that has now grown into one of New England's largest Asphalt paving contractors and does a lot of private and highway paving work in the region. This man was the last to drive the car up until this past weekend. The car was last on the road (legally) in 1980. In the trunk of the car were many treasures, one of which I was told should always stay in the car. Under a small blanket were a dozen small flat stones about 2" in diameter. The second owner stated he and his wife collected these stones on their first date in Wells Beach Maine. Coincidently my family has owned a home in Wells Beach since 1919, which makes the tie to this car and the story a little sweeter. Amazingly enough the car has never been titled as they were not required or needed during the use of the car with its first two owners. I will likely title the car due to its value and estate reasons, and will become the first titled owner. The fella I bought the car from almost backed out of the deal, having owned the car since 2001, he had ideas of restoring it, but I am glad he left it alone. Among other items in the car were three spare hubcaps, a set of spare leaf spring shackles new in their NOS boxes, an original cloth bag for the bumper jack equipment, a wooden hand screwdriver which I believe may have been Plymouth OE, five brand new pairs of windshield wipers, a dozen spare vacuum radio tubes, and a couple boxes of spare fuses. A few sentences about the condition of the car as found, what I've done in the past week, and what I plan to do; General condition; - The car has not run since 1980 after the keys were lost, but the motor turned by hand so I knew there had to be some life in it. - The motor has a reman tag on it, a sticker on the firewall and yellow grease pencil writing on the firewall indicating it was replaced at 99,257 miles. The car now has 27,175 miles, so relatively new considering. Inspection thru the #6 cylinder port has proven the motor is a 230. (big smiles on my face when I learned that). - The body has two small issues to correct, but I likely won't touch them for several years as the patina is very appealing to me. One area on the front edge of the passenger door, and another paint separation issue surrounding the rear stop light on the trunk. The rest of the car is undercoated (rather thickly too) as well as under the hood. - Braking is terrible at the moment despite replacing the right front lower cylinder to make it yard drivable. Brake fluid is orange proving that what ever is in the tubes is long overdue for replacement. - The interior is trimmed rather smartly in - The top is original to the car and has a HUGE hole in it above the front seat. Mechanism goes up and down by hand easily. Vacuum cylinders are as of yet undiagnosed. - The car came with a factory supplied boot cover that is in decent shape. I will attempt to use this for the moment and in the future have a new one sewn up from its pattern. - The car also came with a rather unique and suspected non-oem option: Full Custom Tonneau Cockpit Cover. At first I said to myself what a shame, then I saw it on the car and fell in love with it. Getting her running; - Drained the 37 year old gas, boy does that stink... now to find a place to get rid of 10 gallons of it. - Replaced a very worn fan belt. - Swapped out the ignition switch for an OEM that I had in my stash. - Swapped out plugs, cables, coil. - Replaced both battery leads with heavy gauge OE style. - Added some MMO to each cylinder, placed the car in gear and rolled her back and forth a few times. - Installed a new 6V battery. - Disconnected the gas line to the carb and hand fed her some gasoline whereupon after several minutes of cranking she jumped to life. (and shot out an dust pan full of mouse crap, acorns and dirt from the muffler all over the garage floor.) She ran fine for an hour then died rather abruptly, whereupon several hours of playing whack-a-mole with intermittent doses of ATF has resulted in some less-sticky valves. Latest suggestion was to run some lead additive and to pull the gas tank and clean it. Plans to get her roadworthy; - Remove the gas tank, and thoroughly clean it. Looking for suggestions as to what might be best to use to clean the inside of the tank, noting that it has been wet with gas so residue is assumed to be fairly motile. - New brake cylinders, new brake lines, new MC, new brake switch, all four corners and in between. Curious as to whether or not I will need the miller brake tool (or reasonable facsimile) since I will be using the shoes/pads that are on the car as they are nearly in new condition. Any opinions here? - New top on order from Bill Hirsch to match the original factory colors; Black on tan, (my irish blood appreciates this a lot). Local trimmer has been selected and reports having done two 40's mopars in recent months. (they are on my hit list for names and addresses...) - Fluid changes - ALL of them, including oil, coolant, gear box, and rear end. During the winter months; - Interior betterments. Haven't decided if I want to rescue the interior or go new. I am partial to the patina, but if the cost would be too much to repair it may make sense to spend some dough on new correct color leather. The leather is in decent shape with no holes, but the cotton stitching has disintegrated on the front seat. - Passenger side vent wing window has a broken pivot point and the threaded post that attaches it to the doors A-pillar is sheared off. Both will need to be repaired. Glass will need to be removed from the frame before it can be corrected. Working on glass will be a first for me, and with such a rare part, I will have to work myself up to the challenge. - Overdrive swap. Later this year I will haul the sedan down to our house in North Carolina and park for a few years storage until we begin to full time in the winters down there. Before she goes down I will likely pull the OD and replace shelve it for installation in the convertible. And before I end this, a few notes of thanks for guidance in recent days; - Robin Weathersbee for his enthusiastic support and un-ending archives. - Greg G for giving me his phone number 7 or 8 years ago and allowing me to ask random questions in the middle of any given day or evening. - Young Ed is always there with his matter of fact - Bob Toft for sending me a dozen emails and a bunch of pictures of his car which convinced me to open the safe. I'll be a pest to all you for a while - bear with me. - lastly to my wife, to whom endured the "surprise look what I bought!" without sending a waffle iron flying in the air towards my head. And to her credit has instructed me to hurry up and get it done summer is here! AND said why would you consider selling Ruby?! AND doesn't understand why a 70 year old car is so special but allows me to spend every waking non-wage earning hour with it.18 points

-

I've been asked a lot of things by a lot of different people in my life. Giving advice, lending a hand, being politely asked to leave..., they are all generally of a similar class of requests such that not many are ever a surprise anymore. That was true most of my life until as of late. Now I'm getting surprised all the time. Here's some examples. Looking for any and every excuse to drive my truck, I took my kids to a birthday/costume party. In a few minutes parents were asking for kids to pose in and on the truck. Why not? A couple weeks later, again looking for an excuse to drive it, we used it to go to the local Chili Cook-off. It was pretty easy to just put the old slow cooker in the back and drive over. I stopped to drop off my entry and then went and parked. Within 30 minutes the organizers were looking for the owner of "that old black truck". They wanted to park it in the middle of the event for ambiance. Well, ambiance and picture poising. So many people wanted to crawl in and out of it, my view was obscured more than once. The wife bought a new mattress and box spring from Sears but refused to pay the $80 delivery charge. She was going to bring it home on the top of the Ford Escape. I mentioned that I had a truck which she had not considered. Not sure why she didn't - too "special?". We laughed. So we drove down to the outlet, tied the new items up and headed home. Near home I was trying to make a lane change but was blocked by some lady in a car. She kept matching my speed! I finally just decided to turn right. She ducked in behind us and followed. I remarked to the wife that if she pulled along side that the truck was $17,5k firm. We laughed and turned left. The lady followed. A couple of stop signs later, the car behind us pulled up and waved for my wife's attention. Seems she was getting married Saturday and wanted to be taken to the church and reception in my truck. My dirty, old, smells like gas, farm truck. If you would have seen her smile, heard her excitement, you wouldn't have said no either. What to charge her got me thinking about one of 48Dodger's blog posts. The question was about being able to put a proper the price on our parts or services. I was struggling with that and it took me a while to come up with a clear answer for myself. In the end I didn't charge her a penny. Couldn't really. There was no price on a blushing bride, clearly happy about going to her wedding in an old farm truck. There was no payment large enough for the looks on people's faces, the thumbs up, as we passed them on the way to the church. You certainly could never have found enough of any payment of any kind for the entire church gathering's collective look as we drove off with the newlyweds in the front cab. I got paid with this story. With smiles. Good feelings all around. I'm lucky enough to be in a position to make some people happy. Whether you know it or not Tim, you do the same thing for a lot of people here. Did for me.18 points

-

The transmission is out of my Plymouth PJ and on the bench. I have waited and finally received replacent parts, etc. Before the assembly process begins, I made an image of the gears with a J. Lancaster "Extra Special" large format camera from about 1890. Captured on film with a vintage lens these gears look pretty cool, so sharing them here seemed appropriate.17 points

-

Our daughter Natalie was FINALLY able to get married this past weekend after two postponements and over a year delay due to Covid. It was a great night. She was beautiful, the weather was beautiful and we had friends and family from Colorado, New York, Ohio and Texas make the trip to Florida. The wedding was outside under massive live oak trees with Spanish Moss hanging from the limbs beside a lake. Temps in the low 80s and a steady mild breeze. They used the trunk of my 37 Plymouth coupe for the guests to place their gifts then at the end of the night used it as the get away car. Hopefully you all are seeing things loosen up around you and having opportunities to reconnect with family and friends.17 points

-

Loving my Truck. Just need to try and get a bit more speed out of her. Getting about 40 mph. 360 Flathead 4 speed. Don't believe you can buy ring and pinions for these anymore can ya. Maybe a 5 speed transplant is in need, would take care of the no syncro tranny also. Anyways sorry for rambling I just wanted to share my truck with the group. Have a great weekend! Scott17 points

-

Just being extra cautious as I have seen some suspicious activity by "Guests". Moving forward "Guests" will need to first register to gain access. This provides me a way to review registration information to determine if is a legitimate registration attempt or a spammer. This week I have seen an increase in spammer attempts to gain site access (they get filtered out in the registration process).16 points

-

So I haveta tell you all about this cause my wife doesn't seem to be as excited as me... As some of you may remember, the 3 speed transmission in my meadowbrook im restoring is totally shot. Was full of water, instead of oil, for years. Needle rollers brinneled most wear surfaces. 1st and reverse have major tooth loss. So bad....never seen a transmission this bad. A friend remarked that he thought he knew where one might be, but wasnt sure if it was even the right model. I gave him a hundred bucks and asked him to grab it next time he was in that town. I figured it was worth the gamble. Well, yesterday he showed up at my place with the transmission. I could see right away that it was a the correct 3 speed. But, I didnt recognize what was going on with the weird extension in the rear of it. I got out a wire brush and cut thru the gunk and lookie what I saw (see pic below) A R10 G-1 model overdrive! So I not only got a parts source for my old gear box (forget that!) I've got a transmission with overdrive and it looks to be in pretty good shape. I'll know more tomorrow when I open it up. I will have to swap input shafts, tho, I can tell already. Sometimes you do get lucky16 points

-

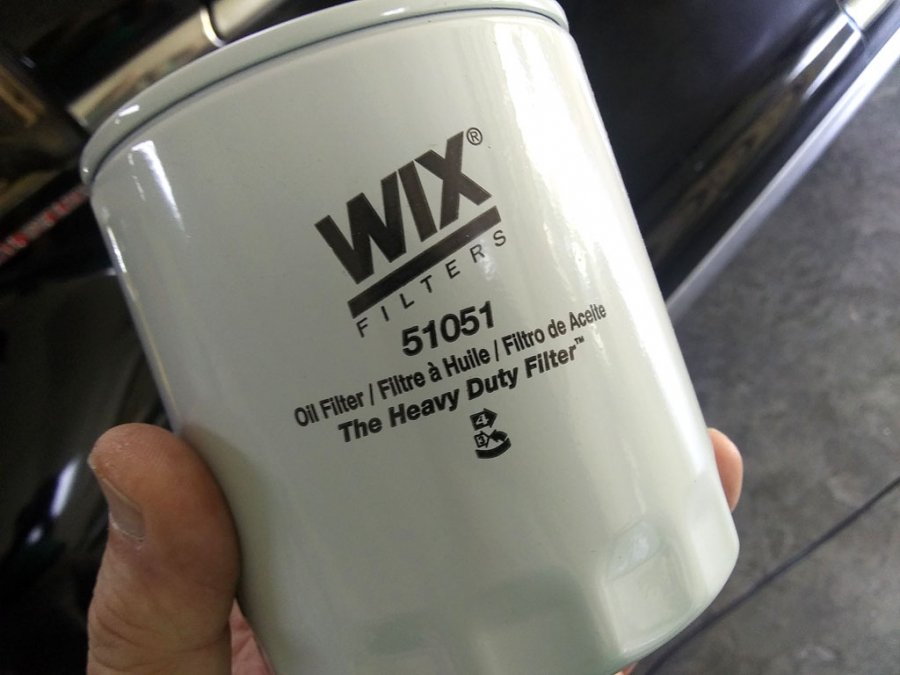

In a previous thread the discussion was centered around whether or not a bypass filter is needed and the best oil for our mature engines. Based on that discussion and pondering this topic for a few days after pulling the oil pan I decided to install a spin-on filter on my non-filtered engine. I've seen a couple of photos on the forum of filter installations but decided to offer a more complete tutorial for the benefit of owners who may want to explore a filter installation. I chose a mount and filter from Wix because they offer a mount and selection of filters that are specifically for bypass operation. Bypass filters are constructed differently from full-flow filters and provide a finer degree of filtration than conventional filters. I sourced the mount and filter from Rock Auto who have not only the filter I use but also the same filter in three additional lengths. I selected the next to shortest due to the confined space around the engine. Here is the mount, part number WIX 24755: Note the arrows indicating the proper direction of flow. This mount is only for bypass installations and has a small 5/8" nipple instead of the more common 3/4" seen on full-flow installations. It also has 1/8" NPT threads that allow 3/16" steel brake lines to be attached with only one 90* adapter. The filter is WIX 51051: The other Wix bypass filters that fit this mount are 51050, 51320, and 51704. A bracket must be fabricated to attach the mount to the engine block. I used 1/8" steel and drilled it for the mount and two studs on the engine head: The two fittings on the engine accept 3/16" brake lines with no modification. I found 12" lines to be ideal for this installation. Accessing the fittings and getting the threads straight deep in the engine compartment is kinda tedious....just consider it a character-building experience. Permatex #2 (non-hardening) gasket sealer was used on the brass fitting where they screwed in the filter mount. I've seen teflon tape used in situations like this but that is risky in oil systems unless you really know what you are doing. A small sliver of tape that breaks loose can create havoc if it plugs an oil passage. A couple of thick washers are behind the bracket to provide clearance for the heads of the bolts securing the filter mount. The threads in the cylinder head are common 3/8" and the nuts on the studs are 3/8" fine thread. One of the studs backed out so I replaced it with a bolt. Prior to installing the filter I filled it with oil. This photo shows the difference between a bypass filter and full-flow---notice the tiny holes through which oil flows in/out of the filter. Filling the filter was very tedious....if I had to do this very often I would rig up some sort of syringe to push oil into the filter instead of spending 1/2 hour adding oil a fraction of an ounce at a time. The filter accepted a cupful of oil before it was satisfied. The finished installation complete with a note on the mileage and date of filter change. The oil lines need to be formed for clearance so the filter can be easily changed. Yes, this is not for those who want a period-correct engine bay, but I like having a modern filter which can be easily sourced through common channels. If my engine is happy....I'm happy.16 points

-

Did the deal on this one today. 1938 P6. Great known history. Solid car. Original interior. D24 engine installed but comes with original P6 engine needing rebuild. Lots of spare parts! Good runner. Test drove it. Looking forward to getting into this car. No plans other than make it reliable, road worthy and safe. Picked up in Victoria BC Canada. I will trailer it home next Saturday.16 points

-

Recently at a car show, I was tending my 1938 Chrysler. Someone approached me to ask a few questions. I was given a lead where a similar coupe was shacked up. Parked for many years. Local here in my town. My interest was peaked for several reasons. 1. How often do you see a 1937 Desoto Coupe? I have never seen one. Let alone right here in this town. 2. Very few Desoto coupes were made in Canada. How many are actually left? 3. I might get glimpse of some original parts. Interior, dash etc... 4. I hear tell of an alligator type hood opening system. Again, not personally see on an old Mopar of this era. 5. Maybe I can help re-invigorate the owner? Maybe I can help get it running and mobile again I was given a name an address. The owner had no idea I planned a cold call at his door. I showed up in my '38 Chrysler and rang the door bell. He appeared and I introduced myself. He was an older gentleman. Pre-"digital age"manners and demeanor. I like that. He saw my Chrysler behind me in his driveway and he lit up. He quickly welcomed me into his home and was more than happy to show me his vintage Desoto coupe. He allowed me to take whatever photos I wanted . We chatted about the car's history and previous owners. We had a very good visit. I then offered him a ride in my '38 Chrysler which he quickly accepted. We chatted and looked happy out on our little cruise. We agreed to meet again in later September. I offered to help him clear out the car and roll it out into his driveway. We have plans to make a You Tube video to showcase the car. He'd never heard of You Tube, but he was smiling and fine with the idea. I offered to help him get it running again if he wanted. The pictures may say 1 million words. It easily happens. We secure a car. We start to dig in. Life happens while we are busy making other plans. We get drawn away from our original plan for the old car. A new car comes along. We enjoy the new car. Then weddings happen. The family grows. Again with the more important things in life, distracting you. You start laying things in the car, against the car, on the car. Decades pass. You forget how quickly the years add up. You turn around and you're pushing 80. What the h e l l happened? Life happened I guess. I am looking forward to digging this Desoto out, and hopefully helping the gentleman. The car is not for sale. I won't be passing along any leads or info. I have no ulterior motives to secure the car for myself. I already have one basically, my '38 Chrysler coupe. Although if I were a rich man with a 6 bay garage, owning a '37 Desoto to append my '38 Plymouth and '38 Chyrsler would be appealing. Then all I'd need is a '37 or '38 Dodge. Lol. That's not happening. As the years pass here in my town, as I continue to network and sniff out leads, I am seeing a growing list of old flathead Mopars. They don't come out very often but they are here it seems. Locally I have located a 1947 Dodge coupe, a 1948 Plymouth Sedan, 1952 Chrysler Windsor, this 1937 Desoto Coupe, plus my 2 Mopars. Someday it would be fun to get us all out together. - Keith15 points

-

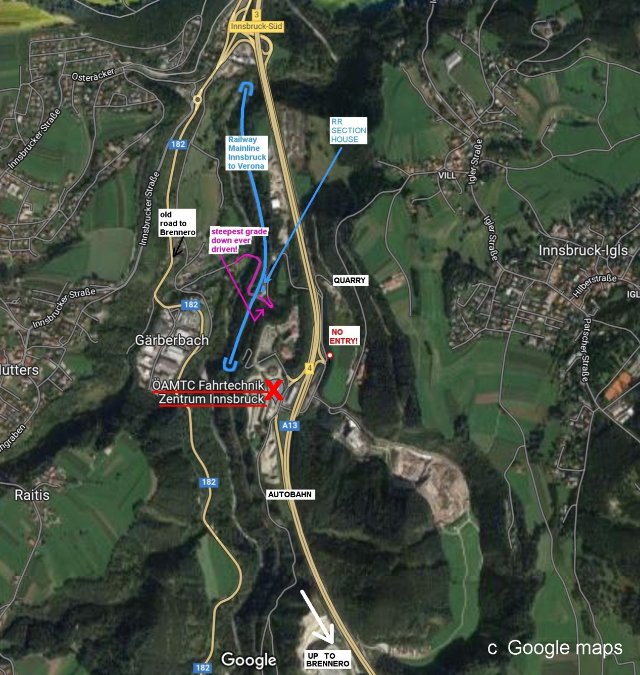

This 3rd of September, we took the Plymouth again for 2 weeks in Italy. I had put a new alternator this spring to replace a shot generator, but it but unfortunately failed in August too. So I had to put a working spare generator which was on hand. Usually, I carry all my spare parts behind the spare wheel, but now I had no time to repair the shot one. We don´t have the autotrain/ sleeping car choice anymore, in Germany they cancelled the whole service! Because of this, we planned to drive the whole trip by car and to stay overnight on both ways. First trip was 400 mls to beautiful Neuschwanstein (castle looms over the hood!). Next morning we continued through Austria 225 mls to Lake Garda/ Italy. We we met traffic jam everywhere. The worse was on the Autobahn incline from Innsbruck up to Brennero in full summer heat. After 1 1/2 hour of stop and go the poor Plymouth´s cluch began to overheat- which forced me to take the next available exit to ÖAMTC (= austrian AAA) grounds. There, I let the car cool down and asked for a connection off the Autobahn to continue on the old Brenner country road. There was none, they told me. Downhill back to Innsbruck to the next exit was the same jam. In the meantime, however, my wife had found an alternative on her cell phone. But stupidly this earth and gravel path seemed only to lead to a quarry and was forbidden for cars. We took it anyway, trusting the cell phone, hoping to reach the old Brenner road. At the Brenner- railroad site we met a group of workers and asked if we would be able to continue. They did not recommend because of a very heavy grade down and a disastrous condition of the road. I dared and made it, but it was extremely steep and the passage under the railroad line absolutely tight. My brave wife had turned quite pale and was happy when we reached our hotel in Gargnano! We had 2 beautiful problemless weeks making 700 mls visiting Brescia, Torino and a lot of small Piemonte towns. (RR crossing near Acqui Terme) (our stylish Samsonites in a stylish Hotel!) (Agliano -Villa Fontana: Piemonte is vine, truffles and hazelnuts!) (near Agliano Terme) Then, we started to the return trip to have 2 nights at Freiburg. At the Milan tollgate again we suffered 1 ½ hour of stop and go in full heat. Now I noticed that the battery was no longer being charged. I changed the voltage regulator - but obviously it was not the culprit. Well, and as I had mentioned before, this time I didn´t have a spare generator on board! Nevertheless, we tried to reach Freiburg, still 250 mls away. We only used parking lights in the numerous tunnels in Switzerland (all one way only and speed restricted) and used as little electricity as possible except for the ignition. Above all, the generator developed an ugly bearing noise. For the last 30 mls in darkness lo beam lights were needed. With 6,6 V at Milan, voltage dropped to 5,9 V when arriving at the Hotel´s garage in Freiburg. That drive was no pleasure! The next morning the ADAC (= german AAA) picked up the car - I would have risked a day drive 300 mls to Düssseldorf with freshly (Hotel-) charged battery, but I did not want to experience the generator bearing´s falilure! We had a beautiful day in Freiburg. The next day, I got a free rental car for the trip home from the ADAC. As I had no hurry they brought The Plymouth to my mechanic in Essen 4 weeks later. In the meantime, I had repaired the other gererator and he could exchange them. Now, the car is ok in his own garage. My wife don´t want to go next summer to hot Italy in Plymouth! Maybe we go to my sister in colder and traffic jam free Helsingborg/ Sweden! Greetings from Düsseldorf! Go (red: travel 2022. The dots are our older Plymouth holidays). Places visited: Düsseldorf: yellow dot red: travel 2022. The dots are our older Plymouth holidays 1 Neuschwanstein 2 Brennero 3 Gargnano 4 Brescia 5 Agliano Terme 6 Nizza Monferrato 7 Acqui Terme 8 Alba 9 Asti 10 Torino 11 Bra 16 Freiburg15 points

-

Hello all I hope I’m in the right place I see it says mid 30d and mopar I have a 1934 dodge coupe that’s been sitting since 1967 Motor was seized and it was dirty I spent a month and half getting parts for the motor did an in frame rebuild new rings main and rod bearings car runs and drives excellent it’s still amazing how a car sat for so long and runs and drives so well But hey it’s a Dodge I am not going to restore it I think it looks great the way it is! Thank you all John15 points

-

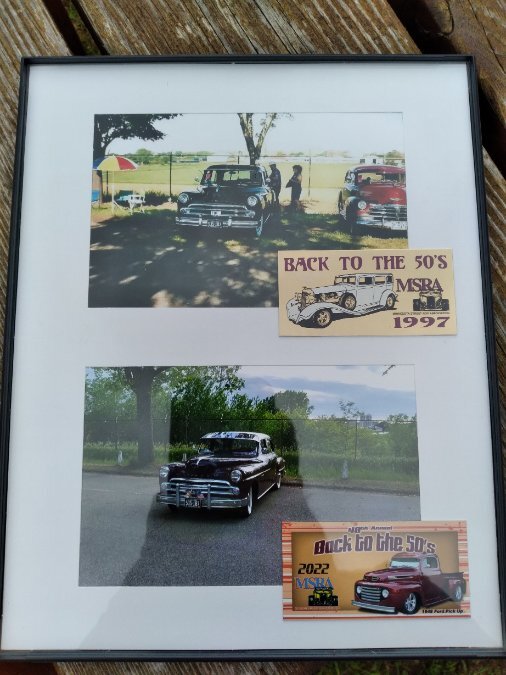

Today was a great day making memories and hitting a milestone. It's a bit of a story, so hang in there. Back in October 1996, Ed and Jane bought a 1950 Meadowbrook with around 69k miles that had spent the last 14 years in storage. It was the first classic car they owned together. Over winter and spring they put in a lot of work, bringing the car back to life. In June of 1997 the Meadowbrook attended its first Back To The 50's car show in St Paul, MN. Over the years they made a lot memories with the Meadowbrook and cataloged most of them. They took a trip to Mackinac Island that included a ride on the S.S. Badger ferry across Lake Michigan. For Ed's 50th birthday they drove it to Tulsa Oklahoma to attend the opening of the time capsule with the 57 Belvedere inside. After 22 years of ownership and declining health, it was time for them to sell. In January of 2019 my wife and I purchased the Meadowbrook with around 92k miles on it. We hit it off with Ed and Jane and formed a friendship. We've gone on a few car cruises with them and keep in touch throughout the year, sending them pictures and updates as we make family memories with the Meadowbrook. Earlier this week I realized the Meadowbrook was 68 miles from turning over 100k. Ed's house is 67 miles away, it was meant to be. I called him up and asked if he'd like to ride along for the rollover. He was in! Today was the day! With my wife and son along, we headed down to Ed and Jane's house. Busy doing math in my head, I missed a turn along the way and didn't quite make it to Ed's house before running out of odometer. So I stopped on the side of a quiet road at 99,999.0 miles and had Ed and Jane meet us. Knowing that he'd likely want to drive, I saved the last mile for him. After a few minutes waiting on the roadside they pulled up behind us. I asked Ed if he'd like to ride along or drive, of course he said "drive!". He was overflowing with excitement to have the opportunity to drive the Meadowbrook again, and for such a milestone! Ed never stopped smiling and commenting how much he's missed the Dodge and how great it drives. We stopped for a couple photo opportunities, just before and right after the rollover mark Then Ed drove back to their house. He let my son drive their Harley Davidson golf cart around their property while we hung out for a while chatting about life, cars and of course, the weather. I had also put together a small gift for Ed and Jane to mark the 25 year anniversary of the Meadowbrook attending Back To The 50's. I found the spot they parked in back in 1997 and took the same photo during this year's 50's. I framed it with the dash plaques by their respective pictures. 25 years of growth and change makes the background hardly recognizable. But I knew it was the spot because of the silos and water tower in the far distance. Out of appreciation, Ed and Jane gave me some incredible Dodge advertisements. I had secretly admired these from the first time I went to their home to look at the Meadowbrook before purchasing it. I had found similar advertisements online over the years, but none this nicely framed. Today is a day that I will always remember. I know Ed will too. I had no idea it would mean so much to Ed to be a part of hitting the 100k mile mark with the Meadowbrook. Making memories is the best part of owning a classic. Get out there and make some memories while you can!15 points

-

Today someone posted on my You Tube channel. They made a nice comment about my Chrysler Royal car. I reached out to connect directly. He informed me his Dad owned my very car. He was able to make a statement that stopped me pretty cold. I have little doubt. He sent me a picture, its dated Oct 1962. I am going to ask some more questions and hopefully learn a lot more about the car’s history. I look forward to sharing more interesting details here. Pretty cool!15 points

-

Many of you have made long trips in your old Mopars but Memorial Day was the first time I've taken the P15 outside our local county. It was a beautiful late spring day and perfect for pointing the old car north on US 31 for the ninety-mile trip to Franklin, TN to visit the grand-daughter and family. US 31 was the primary route for traveling between Nashville and Birmingham before the creation of I-65. The highway passes a quarter mile from my house and I was able to drive it all the way to Franklin without ever leaving the old road. The highway passes through wonderful valleys and gaps as it winds its way through the Tennessee hills and cuts through the historic downtowns of Pulaski and Columbia. The old car was perfectly behaved and proved to be a most comfortable ride. The bias-ply tires tend to follow irregularities in the pavement so more attention is needed than with a modern car. But 55 mph was perfect and the water temp stayed at 170F even when pulling some significant grades through gaps in the foothills. Here we are arriving in Franklin: And of course, here is the future driver of the P15:15 points

-

So, i have been eyeballin' this car for a few years now. It has been sitting next to a shop in my area that I work in. I retired from doing auto body and paint after 20 or so years and took a job for the county doing road maintenance in 2017. I'm not sure if it's a good or bad thing because there are so many old cars and trucks sitting everywhere. I want to buy them all. This particular Plymouth just spoke to me, something about it. I left a note on the gate one day and sure enough, the owner called and said, 2,500 and it's yours. One of the nicest friendliest people I've ever met. I couldn't pass it up. It has not a lick of rust anywhere. Floors, trunk, rockers, all solid. The underside is so clean and solid, looks to not have been driven much. He said the motor and tranny had been rebuilt at some point. He did take the tank out and have it boiled and lined. I have a Mike's carb kit on the bench already and I will try and start it tomorrow. I never name my cars but this thing is so basic and stripped of trim I'm calling it Plain Jane. Sorry for the long post but I'm pumped to get her on the road. I will update it as I go.15 points

-

15 points

-

In the northern hemisphere it’s prime cruising season. Pandemic or not, we go out alone if needed, for a little cruise. Many of us wait all year for summer cruising, and its here right now. Where have you been lately? Post a pic. Share a story. We’d all love to see your car and hear about it! Tonight It was warm here. Overcast. After the sunset I felt the urge to go somewhere. Anywhere. I drove less than a mile to my mail box. Checked the mail...Nothing. Saw a photo op. Then took a “long cut” home around my neighborhood. The old dash lit up in the dark is comforting somehow. That was my quick cruise tonight. Let’s hear about yours. Pics please!15 points

-

15 points

-

After three years of restoration the truck is back on the road. Took a Maiden Voyage to the gas station and am happy to report nothing fell off and everything worked including the speedometer and the fuel gauge! Happy Day and my wife is really happy as this was her father's truck and now it is back on the road. I hope he is looking down and feeling good about how his daughter is taking care of his truck.15 points

-

Half the fun of this hobby for me, is getting to meet the people who share the same passion. please feel free to add your photos of you and forum members you met to this thread (along with a classic) this year I have been fortunate enough to do some traveling and meet and visit with some folks. it started in April at the BBQ in CA. unfortunately, I was so busy "BS ing" with people I didn't take any photos then I had a visitor in June (space reserved for 48D photo ) Tim brought his new bride to Oregon ( I think it was just so he can reflect later and say "at least we don't live there ) was able to meet some guys at the BTT50's GGdad, John U Brent and Young Ed and ggdad, Mike B-1-D-116 EVEN was given a ride in FEF (that was Awesome!) this weekend capped off an unbelievable summer for me, made the drive to see DodgeB4YA and BIG RED EVEN was given a ride in BIG RED! (that was also Awesome!) I am privileged and humbled by the hospitality and knowledge you folks give! Julie and I thank you for a great year! (hey I just noticed.... looks like I better change my shirt )15 points

-

15 points

-

14 points

-

I thought I start a new 2022 thread of all the fun things I like to do in my ‘38 cars. This evening after work it was time to get under my P6 and hook up the speedo cable again. I missed it with all the excitement of my new engine. I adjusted my clutch. It was a little too high I think. In 3rd if I floored it at low speed i could feel it start to slip. Maybe it’s the extra torque we picked up with the 237? We’ll see. Tonight I headed out for brief trip to the carwash. Then pick up a little beer for Sunday’s practice with my band buddies. Gas was $1.959/L. About $6.16/US gallon in US funds. She’s running good. The tranny appears to be all sealed up well. The modern output shaft seal I got on e-bay did the trick. A little sealant on the main and countershaft ends before reassembly dried those up. Getting better every day. Odometer 99,626 miles14 points

-

Hello All, I have been busy in 1964 Chrysler land taking that 92K mile original C-300K and going through it as the replacement daily driver for the 1947 Desoto Suburban. No quite there yet, in another month or so it should be ready for daily driving duties. Then, at some point I can take the '47 apart for a long needed rebuild from end to end. At least the '64 has air conditioning. I do hope everyone has a Merry Christmas, Great Hanukkah, Great Kwanzaa or just an opportunity to read a good book. I raise a glass to all of those who keep the Rolling Museum Pieces on the road and wish you a Happy New Year. James Douglas San Francisco14 points

-

14 points

-

Tonight there was a small old 1938 Sedan in Canada that once again, propelled itself. I am tickled to share this brief clip tonight. One more has been checked off my bucket list. Many of ya’ll have experienced this. It sure feels good. A fresh new 237 engine. Now I just need to go find where I put the brakes. I seem to have forgotten to install them. No workee! ?14 points

-

I bought it! After a minor accident at the gas station first thing this morning, icy roads, 600+ miles and 15 hours later, I got myself a 51 Dodge 1 ton. It's currently still on the trailer at a friend's house, too tired to deal with it tonight in the cold and dark. She's got a few unexpected issues, but the price was right and the truck is awesome. We got a lot of looks and thumbs up on the way home with it. I'm looking forward to warmer temps and getting to know this thing better. For now, here's a couple pics from today.14 points

-

G'day All, This is my 1955 DeSoto Diplomat Regent. I bought it recently and got a Roadworthy Certificate yesterday morning, and got Club Permit plates in the afternoon. Previous owners have thrown a lot of money at it and all I had to do was replace a defective hydraulic brake light switch. It is a SP25-3 with a 250.6 cu in motor (3 7/16 x 4 1/2) and 3 speed with O/drive. The carby is off a Falcon with aftermarket air cleaner. Electric fuel pump next to tank. It has been repainted at some time and the engine fully recoed. Recently the head has been shaved .050". Now to drive the wheels off it.14 points

-

Yesterday I posted about taking my ‘48 Dodge for a run that included some gravel. Today I had the ‘51 Dodge D39 business coupe out for a run. I sometimes like driving down the old service roads that run beside small canals or former canals which is what this partially overgrown road runs beside. I like to park the car and just enjoy the day and a beverage. Today I took the road less travelled and that has made all the difference. (Acknowledgement to Robert Frost).14 points

-

14 points

-

14 points

-

Today my '48 P15 attained a milepost of sorts.....the first foray away from the shop to the other toy box. Thanks to many hours reading archives of your past posts and the helpful hints offered when I asked, the ol' girl smoothly and effortlessly made the 25-mile round trip on a four-lane highway to the hangar and back. She cruises nicely at 55mph and tracks straight down the highway. The only wiggles are due to returning the waves and thumbs-up from other motorists. There is still work to do (house training for one thing...) but after four months of bumper-to-bumper attention the P15 has awakened from its five-year nap and is now a real road car.14 points

-

14 points

-

I just wanted to say I'm sorry to the guys who have been trying to get parts form me this last year....I've been pulled from so many different directions and have had a few life changes at home. Before as a single man (a widower actually) I was able to drown myself in everything Dodge related, stay up really late and sleep in on my days off.....for years!!!!!! Since getting married, to a super fantastic woman who took the time to restore me, It seems like I have been reinventing myself. In a good way of course. But that has come with a few sacrifices, and hopefully I'll be able to play with my spare parts soon. After months of work, we finally sold her house. It was a huge undertaking involving several remolding projects and repair work, but it paid off. That of course led to a dream of mine to own a building in town (clements, ca) to have a business that deals with vehicles. She has embraced that dream too, and now we own a building I've had my eye on since 2009. It took some fancy foot work to get from point A to point B.....but all that paperwork, phone calling, meetings, more paperwork, sweating, more phone calling......etc. again, it paid off. We now own that building!! Today will be our first day with the keys. Its been a new beginning for me since the first time I laid eyes on my wife and I feel very, very fortunate! Digging through the yard parts, pulling suff that guys really need, is a lot of fun work......soon I will be back doing that, but right now I'm enjoying the changes in my life and hope it keeps going. After working more than 30 years for "the man"....it will be fun trying out the other side of the desk...lol. It will be a slow transition from my current job, but I'm looking forward to the adventure. 48D14 points

-

Enough. If you don't like the rules then don't post. I'm closing this thread and if you start another with the same rant you will be banned. We have very few restrictions and the one for limiting ads to the classified section is based on the negative experiences members had when we allowed them in the forums. I pay for the bandwidth, I get to set the rules. Bashing mods/members is not acceptable. Any thing else PM me again and we will address it off line.14 points

-

13 points

-

After 5 months since the last drive of 2021, I got the Meadowbrook out today for the first outing of 2022. I changed oil, topped up the tires and fired it up. The Meadowbrook fired off quick and ran better than I remembered. I forgot how much of an improvement the new pistons and rings made. We took it on a 35 mile round trip parts run. We got a few things for the Corvair we picked up over winter. It's a bit dusty, but it sure is nice to see it in the sunshine again! 2022 will be a big year for the Meadowbrook. 1,539 more miles and it will roll over to 100k. This year will be its 25th year being back on the road after sitting in storage for an unknown number of years. Looking forward to another season of driving memories.13 points

-

13 points

-

My family and I spent the day cruising with the couple that we bought our Meadowbrook from. We were driving the Meadowbrook, they were in their unrestored 52 Olds 98. They are the ones responsible for resurrecting the Meadowbrook from a storage unit and turning it into what it is today. It was their first old car they bought and owned it for 21 years, now it's our turn to enjoy it. We cruised The Great River Road along the Minnesota/Wisconsin border, stopping at a scenic overlook on Lake Pepin. Then we turned onto an old county road that wound through the back country hills of Wisconsin. He took us to the area where his grandmother grew up, showed us his favorite spot in the world that was so peaceful you could almost hear a pin drop outside. Then we stopped for lunch at an old creamery before winding our way back up the River Road to his place where we all sat outside in the sunshine and talked about cars and life. We've put almost 5k miles on our Meadowbrook in the 2.5yrs we've owned it, and today counts as my favorite miles so far. Get out there and make memories with your classics. You won't regret it!13 points

-

Hi all! Until recently I really had no reason to look for forums like this, because I had no vintage vehicle, but mainly because it would just make me extremely jealous of all you who have some amazing oldies! When I was a teenager I had a 1973 Dodge Dart Sport - my most fun car ever! My dad taught me how to make my own repairs, so I learned quite a bit. One evening back then, my cousin took my car for a joyride (without asking) and totaled it! Since then, I’ve always wanted to do a restoration. Well, finally after all these years, I had a 1948 Chrysler Windsor dropped in my lap - well, my garage from a close friend who was paying me back for some money I lent him. I did not expect this! But, it’s a great surprise. And, from what I understand, a good car to start with, because there is still a lot of parts out there for it. It’s in relatively decent shape. The body and interior are great, but my friend says it runs slow - not much power. It’s been sitting in a container for the last couple years without running, so I’ll be cleaning out the gas tank and spark plugs, and see if I can get it going. Then take it to a mechanic friend who will do some tests on it to see the extent of work that may be needed to the engine. Anyway, there’s a lot more I can say, but some of you are already asleep, so thanks so much for this forum and site! I’ve been looking around for a couple days now and I know you all will be invaluable in my process! Here’s my new’48!13 points

-

Pouring down rain this morning. Flood watch in effect. Headed to the shop in the dark when out of nowhere a huge fallen pine tree is hanging into my lane. At 45 mph it hit the roof on the passenger side near the corner of the windshield. Was expecting broken glass and significant damage. Nada.....zip....nothing. Not even a scratch. Got to love that old Detroit Iron. I am positive an impact like this would have messed up a newer truck. And yet the only evidence is a few pine needles. And an elevated heartbeat..... Old Pilothouse trucks RULE! Jeff13 points

-

Clear skies, no salt on the roads an temps in the low fifties. Every other vehicle seemed to be an SUV with a Christmas tree on the roof although there were a couple motorcycles. Ended up waiting at the station. The former Delaware, Lakawana and Western RR station is in Jamesville, NY half way between Onintavia and Orvilleton. The right of way is still in use and carries traffic on the Sesquehanna and Western from Binghamton to Oswego.. The station was built in 1869 and had been moved twice. It is now the centerpiece of the village park along the tracks. It is available for community events. The train still passes the station, but no longer stops13 points

-

A few pics from this evening's cruise. These darn cars make me eat so much ice cream. I wonder how many cones have been eaten in this car over the past 64 years? I was experimenting with my iPhone tonight taking some pics. You can get some groovy distorted looking images. Lots of fanatical waves and thumbs up tonight during my cruise route. I stopped for gas and a guy approached and said he loved the car. Could he take a few pictures? Of course, I replied. Thank you. I took her up several good hills tonight. Testing her for speed and watching the temp gauge. I hit my local hill in 3rd, pulled hard, shifted into 4th and pushed on up, hitting 50 MH. Speed limit was 30 MPH so I did not go any faster. She ran great. Great cars these old Chryslers.13 points

.thumb.jpeg.6ef7997bc12cdbc7a328734758328c5a.jpeg)

.jpeg.01888a0f2205eea29913e456668c7b91.jpeg)

.png.be6cf88bd9acadb5f9de0bacc1dbfe84.png)