Leaderboard

Popular Content

Showing content with the highest reputation since 03/24/2024 in Posts

-

Easter Sunday 2024: Finally had the opportunity to recreate a photo here in downtown Winona; East 3rd and Main St. Traffic was super light where normally it would be impossible to stop and pose the Meadowbrook for a shot. The beautiful buildings on the left were demolished in the 70s in favor of the mini mall. The foreground buildings on the right were demolished to make a parking lot. I put on a new fuel pump and hard line yesterday. Meadowbrook is back in business. Happy Easter everyone! 🙂12 points

-

8 points

-

My 49 has only 38,000 miles and steers pretty good without much wandering and I'd like to keep it that way. I have added oil to it and have determined that the seal leaks. Not unexpected for a 75 year old car. One of the benefits of the KT Keller era of cars is that they use a lot of off the shelf bearings and seals. My NAPA store found the seal CR Seals/SKF ( formerly known as Chicago Rawhide ) #12350 or MoPar 639-837 To get to the seal you pull off the pitman arm and I did this with a cheap Harbor Freight puller. It's a spline so all you have to over come is dirt and rust. The generator can be pushed out of the way to withdraw the sector and cap out of the top. As usual there's two ways to do everything of course and I tend to get it right after trying every other possible way. The top cover doesn't come off the sector until you back off the adjustment screw. My M.O. is to get the sector and the attached cover to the bench and then count the turns of the adjustment screw until they part company. I used 5 turns because it was easy to remember. The idea being if you put it back the way the factory had it, you have a better starting point than if you are guessing. ( especially with the steering gear in the car ) The next thing to do is to check the tapered bearings on the steering shaft. The manual says to push/pull on the steering wheel to detect any slop. I could feel a tiny amount so I took the bottom cover off the gear housing. As luck would have it one of the shim/gaskets popped up while the rest stayed put. The factory put a dimple in the frame to enable you to move the cover down a little but you can't take it off without unbolting the gear from the frame. So I snipped the gasket and bolted the cover back on. The up & down movement of the steering wheel was 2/3 less and the turning effort had not increased. All good signs and time to stop. The shim/gaskets are made in several thicknesses and this was a thin one. In my humble opinion, this is the most important adjustment because even a little up & down slop here moves the sector a lot. You can change the sector engagement with the worm till it's so tight you can hardly turn the steering wheel and the sector will still move if the bearings are not right. Now the problem becomes finding another gasket for the top cover. AMSNOS.com had MoPar 1142-262 for around $8 and when I called they had 15 in stock. ( 706 ) 337-4606 The plan is to put the top cover on the sector, turn the adjustment screw 5 turns and slip it back together with the new gasket. Since I detected no wear on any of the parts it should be very close to okie dokie and it won't leak.7 points

-

I went to a local AACA clubs spring swap meet this morning. At the second building that I stopped at a gentleman had a set of Senior Trippe Safety Driving lights. I examined them and they were complete even had the correct Trippe mounting brackets and the level in the top of the bucket and the original wire and the original Trippe black tipped bulbs. Came home and polished the buckets and then hooked them up to my 6 volt battery charger and the bulbs even lit up, no cracks in the lens. As many of you might know these Trippe lights are not cheap, the price ranges from 1600-2200 for a set in perfect condition. OK, no i did not even pay close to that amount. I asked the seller what he wanted for them and I was thinking at least $1000+. He came back with a price of yes $100. You never saw any one ever get their wallet out and pay the seller. I basically stoles these from him and I asked him if that was his price and he said yes. Also at the same time he had a box of the Autolite BullNose 6v sealed headlight bulbs in a box. There were six in the box. Asked what he was getting for the bulbs he said $20, I then asked each, he said for all six, so another $20 was spent. Got home and tested these and they all work. There is some rust on the edges and on the back but this can be removed and repaint the back a gray color. As you also know MoParpro sells these same light autolite bullseye for over $200 each. So not a bad day of looking for parts. I attached the picture of the Trippe Lights. Rich Hartung Desoto1939@aol.com7 points

-

My Great Grandfather, and guessing my Great Grandmother with the '55 Dodge (I'll be inheriting this summer) and what I believe is a '55 DeSoto. The truck was my Great Grandfather's then my Uncle's, and then my Parent's, and soon to be mine. My Dad just told me that he is getting too old to work on too many toys, and he is giving it to me. It is in a little worse shape than here, but pretty much original. I'll post pictures of it's current state, in the correct area, when I get it out of the barn, but from what I recall it definitely will need a gas tank and fuel pump, amongst other things.6 points

-

For several years I was hounded about getting a dog. Pun intended. Didn't want to do it. Not because I don't like dogs but because I do like dogs. I get too attached. I finally relented and on a Saturday morning and we took off on a two hour ride - one way - to pick up a basset hound puppy. That was eight years ago. Daisy is my buddy now. She hurt her back a few days ago and it was after hours. And the vet we usually use was going to be out of town for the Easter weekend and wouldn't be back until Monday. So I found an alternate local vet and took her in yesterday. OK I'm almost to the point of this post. I expected it to be a thousand dollars when I went back to pick her up. But I'll pay that - I don't skimp on medical stuff when it comes to people or pets. That's just one of the things that has to be done. BUT the bill was only 500 dollars - still not cheep. Now being of the old car mind set that means that I have 500 dollars left over to get some parts for the 47 P15. Not sure I'll get away with that😂 PS: I expected spinal problems in an old dog. But turns out it's only a pulled muscle. Really good news.6 points

-

6 points

-

Well, same here, the pup eventually become family and usually cause less trouble or heartaches. My little dog asks for nothing, gives all. I have had a number of dogs over the years and yes, they all been good animals. But this little guy, he is very special. He was 14 last Christmas...I have had pugs since early 80's....they my favorite breed. Here he is doing his Don King impression.6 points

-

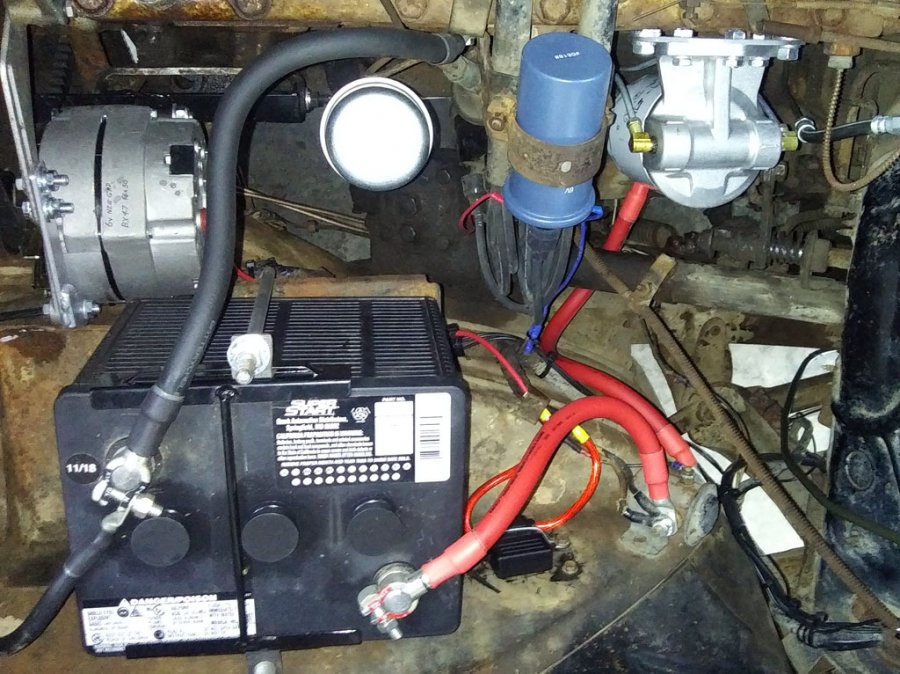

Or install a 6v alternator, keep the 6v battery and drive happily ever after. 😁6 points

-

Forum started in 1998 on some open source forum software. Was pretty buggy and required a lot of time to keep it working. Basically as the number of posts grew the index would get corrupted and have to start over. Remember the forum updates when we started anew?? Then went to a commercial product, I think it was vbulletin. I think they got bought and then support got pricey. Started looking for another solution and ended up going with Invision, partially because they had tools to migrate from the previous vendor. Migration was a pain, but got it done. Invision has maintained a fair price structure and is good about bug fixes and security updates. Support has also been good. They are reducing some of their features like the store for physical item sales, which is going away very soon. They don't think they can compete in that market with all the other marketplace solutions available. Same was true of the chat function. FYI additional security with the ISP has been implemented and guest access is again available.5 points

-

5 points

-

5 points

-

I’m sitting on the sidelines, watching. Minding my own business. I get dragged in to one of two discussions that will never be solved: 1. What oil to run? Zinc additive? 2. 6V or 12V? I’ll respond based on my experience and what makes me tick. 6V? Cool. I wonder how that system works? Let’s rebuild it and see if we can make my car perform like it did when it was new. I’ll learn a ton along the way plus it’ll feel good to fix something I know little about. Hmm. The wiring is old and crusty. A bit of a volatile mess. Do I order a new replacement wiring harness? Pretty pricey. Plus how am I going to improve my soldering and harness building skill-set? I’ve got plenty of time that I don’t seem to mind wasting. I sure don’t like paying someone else to do what I can learn to do myself. I sure don’t like letting money out of my wallet very quickly. Off we go. 6V it is. I’ll read and study all about it. I’ll make my own harnesses and upgrade wire gauge too. I’ll add relays & fuses. A 6V-12V converter too for my iphone. I’ll rebuild switches. Sockets. Salvage and re-use rare wire connections. Voila. My car starts up immediately and runs like a dream on 6V. I feel good. I like it. It’s different than everyone else on the road. It works well. People I meet like to talk about my 6V system. These experiences feed my brain good things about the vintage car hobby. I’d rather spend $1200 on books, tools and parts. Then another 40 hours of my time perfecting my skills, versus spending $1200 on a new harness assembly. So now I’ve appeased myself and quelled my curiosity. I like 6V and I’ll stick with it. Both of my cars are 6V and I’ll keep them that way. You can do whatever makes you feel good and secure. 12V if you like. The other 5 vehicles around my house are all 12V. They work fine too. No complaints except they are way harder to work on! Lol. Not sure I helped settle anything here. Now you just know me a bit better.5 points

-

Personally (from all the posts here) I like dogs, but just don't have the time for one. You have to be around (or someone) every so many hours. When we moved to our place we inherited Puma, the shop mouser. She's had her adventures (lost for 6 weeks after a broken carrier outside the vet's office....but we got her back..which involves the USPS phone call...long story). She's my little buddy in the shop and when she's gone, I will miss here dearly. Growing up on a farm I never got too attached to the cats as they were outside animals and could literally disappear overnight. But she has clawed her way into my heart. She's over 20 years old (we actually figure 22 from discussions with the neighbors) now and spends the majority of her day sleeping, but still needs to take a nap at the end of the day on dad while he makes sure nothing will go amiss overnight in the shop after welding, maintenance or woodworking. Hemp oil has given her a new lease on life this last year or so, the arthritis pain is kept at bay and she still plays, runs and jumps. I highly recommend this for older pets! When she's gone, I'll be alone out there, but won't find a replacement as I worry too much about yotes and eagles. I give you the engerizer bunny kitty and shop supervisor: Puma!5 points

-

Our current girls and are best friends! Roxie on the left, Queensland-Aussie mix, and Sunny, 100% Heinz 57 mutt! One suggestion after some substantial previous vet bills with one of our other dogs is get pet insurance. Cost is easily offset when you have those unexpected emergencies. Both my wife and I have had cats and dogs our entire lives and I don't see how you can live without them!5 points

-

4 points

-

Been awhile since I've been in an engine but I would recommend that once you remove the lower cap place some kind of sleeve over the threads of the cap bolts , rubber/vinyl hose, masking tape, etc. this will avoid worries of bolt threads scraping the crank shaft as you push the piston up per Sniper's recommendation. Just a thought.4 points

-

This adventurousness, driving about to see the eclipse-distracted, or wandering through a riot, seems like when I find myself driving through a snowstorm. I tell my wife that I was going out to see what sort of an idiot would drive around in conditions like this.4 points

-

We always had dogs, I love dogs. We had cats too, the last one went missing a couple years ago. Our neighbor has outside cats that hang around our place sometimes. I don't mind, they are good mousers. Our last dog was a Chocolate Lab named Coco who we had to put down the same week I lost my Dad. Hardest thing I have ever done. My wife said "no more", she can't handle the loss again. I hate the loss, but the joy when they are with us outweighs the loss for me. Just about the time I thought we might be ready to adopt another dog, 7 years ago, my daughter adopted a rescue. Remmy is a terrier mix with an unknown background, although the vet says his past was very bad based on a physical exam and his obvious trust issues. Remmy is a lone wolf, he doesn't like other dogs, or cats. He takes a little while to warm up to most people too. He and I became best friends quickly. Although he lives 2.5 hours away, we visit often, and we dog sit whenever needed. When his human brother was born, it really freaked him out. I slept on the floor in the living room with him for about a week until he adjusted to a baby making baby noises overnight. My grandson is now two and they get along pretty well, but sometimes Remmy just needs his space. We brought him home Monday after Easter to stay with us for two weeks, a longer than normal visit, but my daughters family has several things going on over the next couple weeks and rather than shuttle him back and forth, he will just visit with us. I love it!4 points

-

4 points

-

Buster dog hinting that he'd like to have what I'm having. We've had seven dogs over the past 50 years. This guy is not only the largest dog who lived with us, but also the most well behaved. He isn't a snuggler, but he can't control his licker. Lot's of kisses. He's an absolute gentleman when riding in the backseat of the DeSoto, and he has made himself the official protector of it. If someone gets too close to the car while he is in the backseat, he will let out a low growl in his throat if he doesn't know them. No snarl, no bare teeth, just the warning. Of course, if you passed him a burger, the car is probably yours.😉4 points

-

4 points

-

Rest assured I'm not leading the 6v marching band. But I think something we need to consider is these old cars were daily drivers back in their day and they started reliably. People weren't converting them to 12v just so they could get them started every morning. I have to wonder how many times a 12v conversion is performed just as a band-aid applied over systemic problems such as poor wiring, a sluggish starter or a battery that isn't being kept fully charged by an anemic generator. Perhaps many reliability concerns could be addressed by making sure the existing 6v system is in optimum condition by addressing basic maintenance issues. These old cars worked very well in their day, there is no reason why they can't be as reliable today if the electrical system is in good condition. Having said that a set of good battery and starter cables along with an alternator will go along way toward keeping a 6v car happy.4 points

-

12V if you prefer. That’s fine. I like 6V for old school cool factor. I like it when young drivers want to check out my old car. I point out the positive ground 6V system with a generator. Vacuum wipers. Suicide doors. Tube radio. Split hood. Flathead engine. Bias tires and more. They are often stunned and awed. I like being a custodian and teacher for these old systems. That’s just me.4 points

-

It kind of looks like the shifter bushing my 49 has. I wrote in about it a couple of years ago. My shifter was getting stiffer and stiffer and hard to shift. Pulled the whole thing apart looking for the problem. Turns out the “bushing” is a piece of webbing and it had dried out. So I lubed it up and it has worked fine ever since. Your steering shaft bushing looks very much like my shifter bushing. If you oil it, it might swell up and work fine. Lastly if your steering wheel moves up and down when you pull on it, you need to adjust the steering gear bearings. The seal in mine leaks so that’s a job I have to do as well. I’ve been through the shop manual prepping to do it. I have the front sheet metal off right now ( a rust prevention project ) so I can get good photos for a write up coming soon.4 points

-

I have an admittedly tight focus on the KT Keller cars, so that's what I research and play with. It's all about having fun after all and those are the ones I like. I am a huge fan of Overdrive transmissions because they don't really change the charm of the cars and actually add to it. When you put one in your car your speedo will be off at all speeds because the speedometer pinion gear was selected for a 4.1 ring and pinion. The good news is you can swap out the pinion from your old three speed to the O.D. and all will be back to normal ( assuming your speedometer doesn't need service ). But what if you changed the rear end ratio or the tire size? I don't advocate changing rear axles because I don't see much to be gained there. You can easily change the differential carrier ( aka 3rd member ) in a Plymouth if you want another ratio. Where I live there's lots of open road with highway speeds of 55 to 70 so optional ratios, tires and O.D. go well with my Plymouth. My P17 Coupe came with 6.40-15 tires ( modern equivalent 195/75/15 ) and a 3.73 final drive ratio so the speedometer pinion would be a 17 tooth gear ( p/n 652-848 ) for an example. Chrysler designed the pinions to use the same 6 tooth gear on the output shaft so you only need to change one gear to correct the speedometer. One thing you find out right away is selecting speedo gears is not an exact science. You can get close and you might hit it right on the button but you more likely will be over or under by 2 or 3 mph. That's why the Highway Patrol has an enforcement tolerance. So let's look at tires first 6.40 15 = 195/75/15 standard tire for a P17 6.70 15 = 205/75/15 standard tire for a P18 7.60 15 = 225/75/15 an optional size tire Final drive ratios 3.90 very common on long wheelbase cars 3.73 standard ratio on many optional on all 3.54 optional Chart of ratios & tires vs speedometer pinions 3.90 6.70 15 17 tooth pinion 3.73 6.40 15 17 tooth pinion 3.73 6.70 15 16 tooth pinion 3.54 6.70 15 16 tooth pinion All 7.60 15 16 tooth pinion So you can see you're not going to get an exact reading but you can get close enough to avoid a ticket. The part number for the 16 tooth pinion is 652-846. I have found that if you have the number for an obscure part the parts house will look to find it in their inventory but they are likely to blow you off if you just say "I need a 16 tooth speedometer gear." Happy hunting!3 points

-

Yup, between 65 and 70. When I had earplugs in, I tended to go faster, haha....3 points

-

Hello, I recently purchased a 47 WD21. As far as I know, it’s 100% original, but I honestly know very little about these trucks, so I’ll be visiting the forum frequently. I do not plan to do any modifications, but upgrading the oil filtration system does interest me. If anyone has done such an upgrade, please let me know your thoughts. what I know (or have been told) about the truck: New water pump, new brakes, new tires, new glass, new shocks, 12v, fuel system cleaned. I drove it home about 1 hour through the mountains. I learned a lot in that hour. Like she handles similar to a backhoe with low tires ha ha, and 3rd gear is the only gear I can get my foot on the brake pedal. But she ran great!3 points

-

Thanks sniper and DJK for digging up info. And here's my two cents about electric pumps. First off, I love 'em! And here's why: When one of my vehicles has been sitting for a long time, I don't have to waste precious battery capacity cranking the motor to get fuel up to and in the carb. I also put a electric switch in the supply line to the pump so that, in Autumn when I'm putting cars to sleep, I can turn off the switch and keep running the motor until it dies. This does a good job of draining the carb, reducing varnish build-up. Yes, I could use a gas additive (and I often do), but with lots of cars and equipment, and full gas tanks in each, that's lots of Stabil! And, in regards to leaving the mechanical pump in the line, I've done that numerous times, but one thing to consider is this: if you do that and the rubber diaphram of the mechanical pump fails, you'll get raw gas going into your crankcase and diluting your oil... and not know it!3 points

-

Public Service Announcement.Time to spring into warm weather driving mode. Remember to reverse your car's battery cables to change heater to cooler function. Happy Motoring to all.3 points

-

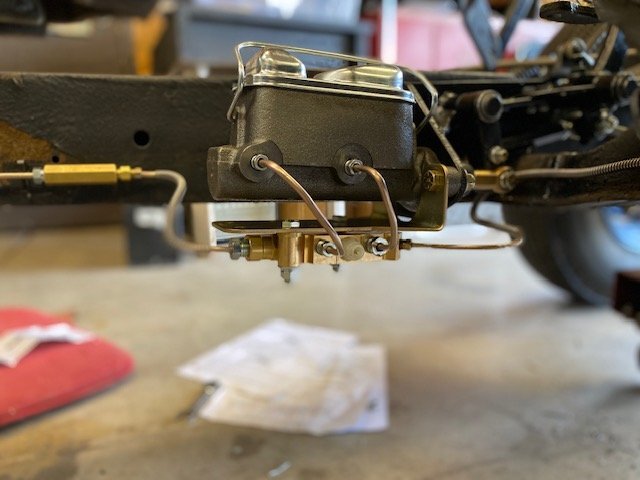

I'm moving right along on my '52 Suburban build. This week I finished upgrading the brakes to a dual master cylinder from ECI Hotrod Brakes and Brackets. It's very well made and I had no trouble fitting it to my existing underfloor brake pedal. The instructions were good, and the only thing I had to buy extra was a bracket off eBay, to hold the combination valve below the master cylinder. I tried to re-use all the original clutch parts that I could, but needed to add a bit of metal to the clutch pull back spring arm as it was wallowed out, and install new clevis pins. My wife donated her old tan purse for the clutch fork seal. I saved some $ by using the P15D24 Forum template and made one myself, as AB and others are all out of stock. Next-steering column fun! ECIChrysler.mov3 points

-

Ok. So. That was probably the most spectacular celestial thing I've ever seen. I still wouldn't go out of my way to see another total eclipse, but I am definitely glad I got to see this one. We were in the 100% zone, the skies were crystal clear, and we had an unobstructed view, so for three minutes and some seconds, all you could see was the sun's corona, and three stars/planets that popped up, seemingly out of nowhere. Like turning on a light switch. Funny light effects for an hour leading up to it during the partial eclipse, then BAM, it's dark, the temp dropped a good ten degrees, the wind stopped, everything got quiet, and you could look at the moon/sun with the naked eye, surrounded by the awesome display of the sun's corona. I guess I was expecting groups of white-robed Druids to pop up chanting pagan rituals, not that that didn't happen, but I didn't see any. I had to go through town earlier in the morning and it was already crowded at 0800, but then we stayed home. Had some friends over later to watch the event, who said it was packed downtown when they went through at about 12. Doesn't look like we got the full quota of madness that was predicted, but still got enough people to challenge our planning and preparations. Traffic on I-95 northbound was not quite bumper to bumper, but it stopped to watch the event for a good 45 minutes. The day isn't over yet, though, and tomorrow is worthy of staying home, too, everyone who trickled in over the past three days will be leaving at once. I got a kick out of this - there was a rumor going around that Taylor Swift flew into the Houlton International Airport on her private jet to witness the total eclipse. A friend was assigned to monitoring inbound air traffic, (his wife and kids were who came to our house to witness the event), all he would say was that a fancy private jet flew in, but he wouldn't confirm/deny her presence, despite our encouragement to propagate that rumor whether true or not. So, if you've never been outside, standing on the ground, to actually see a total eclipse in person, I think you've missed something worth seeing. Won't be another one in North America for something like 20 years.3 points

-

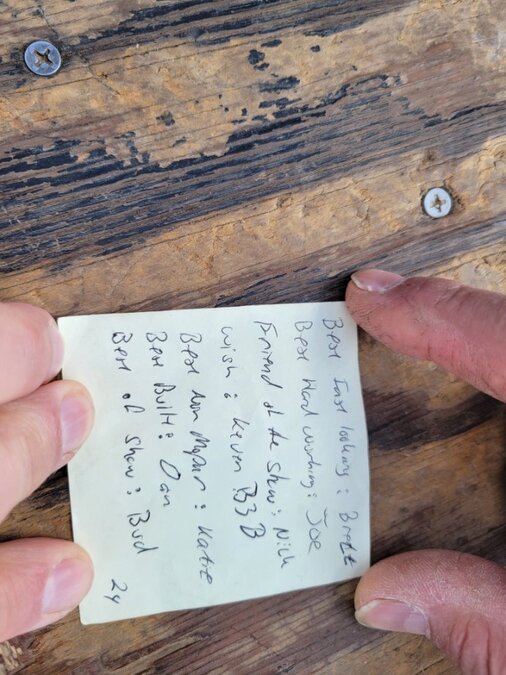

My photo dump. Sadly we missed "Friend of the Show" pic. I'll update pics with the awards tomorrow. Twinsies the grand master Tim! Best Non Mopar: Katy 71 Range Rover Best Hard Working Truck: Joe Light Blue B1/B2 Best Built Truck: Dan Red C series Best Fastest Looking Truck: Brett R/T Challenger (it identifies as a truck) Best of Show: Bud Red modified B3/B4 Not shown: Friend of the Show: Nick 4x4 B1/B2 Wish you were Here: Keven B1B (sorry have the year wrong in the note, I was looking at Brent)3 points

-

Success! Completed the Rusty Hope disc brake conversion today. Looks like the truck will make the BBQ after all. OMG! What a difference! It feels like power brakes. I’m willing to discuss this process at the BBQ if anyone’s interested. There were several issues along the way. It’s not the straight up bolt on project that I imagined and the biggest hang up was the first machine I went to. That had my spindles almost two months! Any way, I’ll be there…3 points

-

Ok, I've finally got a few things that worth an update. The bed panels are done and the front fenders are mostly installed. I'll be the first to admit the bed panels aren't perfect, but they are good enough for me. The trick is once installed, drive fast enough that people don't get a good look at them The panels are still at the painters, which is good because I currently don't have any room to store them. I've had a lot going on and the shop was packed with stuff so it's been really difficult to work efficiently. I finally managed to make room and once the front sheet metal is all bolted into place then I'll be able to move things around to make an assembly area to build the bed. This morning we worked on fitting the front fenders. Started on the right side and fought it tooth and nail to get the gasket and bolts between the front of the fender and the front nose. The left side we were able to apply lessons learned and it went a lot faster. The bolts holding the fenders to the nose are now tight, but the bolts holding the nose to the radiator frame are still loose. We're having difficulty getting the door gaps to stay put. I can pull the nose on the left side and get a decent gap but after letting off on the pressure it moves back closer to the door. Tightening the bolts on the left side don't seem to help it stay in position, it still springs back somewhat. The passenger side gap is slight larger than it should be so I think the cab needs to rotate slightly. I'm currently struggling with finding a method to pivot the cab (the four bolts are loose). I believe the front left bolt is somewhat of a pivot point and what needs to happen is the passenger side needs to pivot slightly forward. What's the best way to do this? It's been around 28 years since I dismantled the truck and its kinda weird to see fenders on the truck!3 points

-

3 points

-

3 points

-

Ready for Easter Sunday. Winter projects done. Time for spring. Rebuilt rearend all new brakes MC to wheel cylinders, new kingpins and bearings.3 points

-

It's amazing what we'll do for pets. Buster dog, a Border Collie/Pointer/Shedder mix, had his spleen removed last summer. It was a rough week for all of us. I slept on the floor next to him the first couple nights after his surgery. I don't remember what it cost but it was spendy. He's back to his big old goofy self again. He's also waiting on me to get this stupid cast off my foot so we can do our morning 2 mile walks again. Two more weeks, buddy.3 points

-

I'm not following the cheaper to go 12v unless you are referring to the incredibly complicated system the original poster is describing. Less than $150 for a new 6v alternator and nothing on the car has to be changed. I would, however, upgrade to the proper 6v battery and starter cables if they are not present, that will solve the cold weather starting problems.3 points

-

had to slap on the chains to collect the last of the sap last weekend.. season is done... time for clean-up.3 points

-

I like aluminum paint, it dries without any buildup. Check the inside of the tires for any tags, that could eventually rub a pin hole in the tube. I wiped the inside of the tires and the tubes with corn starch with a cloth. It doesn’t need a lot. I paint the bead of tire with rubber lube, so the bead slides easily on the wheel as it sets, you can put the lube on the wheel seat to ensure a soft seating of the bead. The flap doesn’t need any lube. Set the opening of the lock ring opposite the valve stem. I have a special hammer/mallet with a duck bill on the other side. I use the rubber part to tap the lock ring into place as I fill the tire slowly by adjusting the pressure on my regulator. This assumes that your rings are clean and no cracks, they have been painted and the notch in the wheel where they lock is perfectly clean. I’ve trashed wheels and rings that had been beaten with metal hammers. The lock ring ends should be almost touching when done correctly. Any questions, ask, it is a risky job even if you’ve done it before. These are 16” wheels, but the same design as the 20” wheels that I have. Once the bead is set and the lock ring is secured properly, I let the air out and refill with the valve core installed to eliminate any tube wrinkles. After you get it to pressure, you can bend the valve stem for access when the wheels are on the truck. If there is anything you don’t understand, ask. Rick D.2 points

-

Another vote for making your own. It’s like a puzzle to solve. You screw a few up. You learn. You get better. Building and shaping your first ever 3 ft line across the left rear axle housing? Order two 25 ft rolls of 3/16” brake line tube. 😄2 points

-

you may be onto something Sniper, I am going to say a rolling wheel gathers no red paint.....2 points

-

See now a song comes to mind I see a black wheel and I want to paint it red Apologies to The Rolling Stones2 points

-

I looked at the license plate mount this afternoon, and tried to get the old plate off to be able to get a decent picture. It isn't quite as I remembered. The center (vertical) bracket hooks under the bumper, and the center bumper bolt passes through it, securing it to the bumper. Then there is a horizontal c channel bracket fixed to it (welded?), with long slots, to accommodate various mounting points for the different shapes of license tags used during that era. This is the best I could do, as the tag mounting bolts are rusted fast, and just turn on the back side. (I could have broken the tag off, but didn't want to ruin such a perfect license plate.... )2 points

-

2 points

-

In the past I have used full covers when storing my car indoors. More recently have gone to covering the flat surfaces of the car with old cotton bed sheets only. I was concerned the full cover makes the inside of the car dark. Mice love the dark. Also, the bed sheets are easily washed compared to a full car cover.2 points

-

2 points

.thumb.jpeg.28cb36506a6b17cd30e7d4a22504384d.jpeg)

.jpg.b4d2e66dd2d75ec0841a1288a9cbcfb9.jpg)