Leaderboard

Popular Content

Showing content with the highest reputation since 04/18/2024 in all areas

-

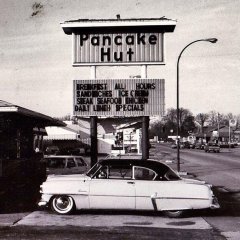

My Great Grandfather, and guessing my Great Grandmother with the '55 Dodge (I'll be inheriting this summer) and what I believe is a '55 DeSoto. The truck was my Great Grandfather's then my Uncle's, and then my Parent's, and soon to be mine. My Dad just told me that he is getting too old to work on too many toys, and he is giving it to me. It is in a little worse shape than here, but pretty much original. I'll post pictures of it's current state, in the correct area, when I get it out of the barn, but from what I recall it definitely will need a gas tank and fuel pump, amongst other things.6 points

-

6 points

-

I speculate that pre ww2 bolts were more likely to be cut but with the advancements in the military equipment, i.e. planes, etc, stronger threaded fasteners were needed. Just a thought. dan...2 points

-

I've used Rustoleum and Tractor Supply's implement paint for rust "proofing" on many projects over the years. No paint will kill rust that isn't addressed but it can inhibit surface corrosion on clean surfaces. Two VW Beetle floor pans (inside and out) and running gear received the Rustoleum satin and gloss finishes and both have held up well for over twenty years. I usually use a brush because the paint can be applied thicker and the cost and mess is much less than spray cans. I've also bought quarts, thinned with mineral spirits and shot it with a spray gun when that was the best option.2 points

-

The dimmer switch might have corrosion on the contact points. Press the dimmer switch several times to clean the contacts. Check the fuse for the light switch might be blown. Go to the headlight junction block and use a test lamp to see if you have current flowing to the connection block. If you have power to this section then your lights might be toast. Pull a headlight bulb disconnect the wire connecter then test with a 6 volt battery charger to see if they light up. If they light up then check each connecter at the base of the bulb to see if you have current flowing to the socket. Also could be a grounding issue or maybe the bulbs are bad. Just basic diagnostic procedures. Rich hartung desoto1939@aol.com2 points

-

The filter is far from the headers. The pipe that it is close to is an intake runner, and when the engine is running those runners stay very cold. That's why I built it like that. Cold air is denser and allows more power to be made. The long runners introduce a ram effect on the intake charge and produce more power. This was a question about installing the windshield and rear window.2 points

-

I like aluminum paint, it dries without any buildup. Check the inside of the tires for any tags, that could eventually rub a pin hole in the tube. I wiped the inside of the tires and the tubes with corn starch with a cloth. It doesn’t need a lot. I paint the bead of tire with rubber lube, so the bead slides easily on the wheel as it sets, you can put the lube on the wheel seat to ensure a soft seating of the bead. The flap doesn’t need any lube. Set the opening of the lock ring opposite the valve stem. I have a special hammer/mallet with a duck bill on the other side. I use the rubber part to tap the lock ring into place as I fill the tire slowly by adjusting the pressure on my regulator. This assumes that your rings are clean and no cracks, they have been painted and the notch in the wheel where they lock is perfectly clean. I’ve trashed wheels and rings that had been beaten with metal hammers. The lock ring ends should be almost touching when done correctly. Any questions, ask, it is a risky job even if you’ve done it before. These are 16” wheels, but the same design as the 20” wheels that I have. Once the bead is set and the lock ring is secured properly, I let the air out and refill with the valve core installed to eliminate any tube wrinkles. After you get it to pressure, you can bend the valve stem for access when the wheels are on the truck. If there is anything you don’t understand, ask. Rick D.2 points

-

Another vote for making your own. It’s like a puzzle to solve. You screw a few up. You learn. You get better. Building and shaping your first ever 3 ft line across the left rear axle housing? Order two 25 ft rolls of 3/16” brake line tube. 😄2 points

-

preformed and then curve and bent to fit a box for shipping, you better off making your own tailor fit set.......2 points

-

Here's a possibility. I wonder if the Dodge rod bolts have threads that are cut, while the Pontiac rod bolts have rolled threads. Rolled threads are formed by dies that displace (smash) the material into the shape of threads, without removing any material. This results in threads that have larger outside diameter than the adjacent shank section of the bolt. On the other hand, cut threads are just that - they are made by cutting material away to achieve the thread shape, so the threaded section diameter will not be any larger than the diameter of the adjacent shank. It's kind of hard to tell from your photo, but it looks like that might be the situation. If so, then accordingly, the Dodge rod might be made with smaller bolt holes to snugly fit its cut-thread bolts, but the Pontiac bolts, with their rolled threads are too large to fit. I have a couple of Dodge 230 flathead rods at home, along with their bolts, and I can tell you that the threads in those bolts have the appearance of being cut, which surprised me, since I have seen other Dodge flatheads that have the appearance of having rolled threads. I have no reason to think that those are not the original bolts, and perhaps they were early rods that used cut-thread bolts. I could take some measurements and photos of those rods and bolts some time in the next few days and we can see if they match the dimensions of your bolts. We can also see how thin my other rods are (the ones that used rolled-thread bolts) in the wall between the bolt holes and the bearing saddles. I remember them being pretty thin. We might find that you have room to ream out the bolt holes in your rods to accommodate the slightly larger Pontiac bolts, or some aftermarket bolts, such as those from ARP. From the strength and durability (fatigue) standpoint, the bolts containing rolled threads are very much preferred. I believe virtually every manufacturer uses those types of rod bolts nowadays and have for many, many decades. I remember seeing early rod bolts from other engine makes that used cut-thread bolts, but I think most everyone moved away from that type of design long ago.2 points

-

As others have said, the Dodge/Chrysler/Plymouth/DeSoto flathead sixes have hardened exhaust valve seats from the factory, and they are very capable of handling modern, unleaded gas without any issue. They came that way starting in 1933 or 1934, and remained that way throughout all years that they were produced, which was well into the 1970's. So you don't need to worry about that.1 point

-

Moparpro is a great place to way overspend on parts. There is nothing special about him.1 point

-

My 51's vacuum line is routed similarly, across the head, Ian has a 40? Odds are they changed it.1 point

-

Did not try that... The "gas test" was only performed because I spilled it while filling-up 😂1 point

-

Yeah that is the stock correct P23 vacuum advance line. It is supposed to go over the head as shown. It's never been bent out of original shape either. Fuel line looks OE too.1 point

-

I have not seen a paint that would hold up to the effect of Dot3 fluid.....powder coat may stand up but would be in my opinion stained at minimum. Most areas you cncerned with are likely not subject to ease of powder coating either. Go DOT5 or forever be ye careful.1 point

-

I should have stated more clearly, that I am only referring to the sedans, the design with the continual slope from roof top to deck lid. The other style sedans may well be different all together in that area. But on these P15 sedans, the arm rests mount in the exact same position in relation to the rear wheel wells. I will have to do some actual part to part comparison to know for sure that they are exactly the same. But if anyone else is following this topic, and has patterns for the P15 sedan rear arm rest upholstery, I would sure like to get in contact with them.1 point

-

I think the vacuum line is suppose to follow the head around the front, not over the head. As for the fuel, perhaps parts of the alloy disolved out of the metal, leaving a sponge-like material. Or what you are seeing is vapour condensing. That's my guess. The tops of these carbs do warp easily, I usually tap the metal between the bolt holes with a small hammer, then sand it flat on a true surface. The hammer makes it so you dont have to sand as much to get it flat.1 point

-

All Mopar flat sixes (and 8's) can from the factory with Valve seats (hardened). NO need to change anything but maybe timing if you have been running a higher octane gas. They have No problem running non leaded gas- never did! 😁 DJ1 point

-

My P15 had developed a habit of occasionally going dark between high-beam and low-beam switching which made me wonder if the switch was going to totally die soon. A really dark road and the proximity of deer meant the car was more likely to pull this little trick. I replaced the dimmer switch and now the lights are reliable. I was pleased to see Rock Auto carries the switch in the Standard brand which is usually a good bet for aftermarket. I had to replace the old bullet connectors on the harness with ring terminals but that was a minor blip to get a new switch. https://www.rockauto.com/en/moreinfo.php?pk=445771&cc=1486874&pt=4340&jsn=3901 point

-

That's great news! No need to PM, you can just post them here, I am sure everyone would appreciate these, for reference 😀1 point

-

1 point

-

Stainless, when in contact with ferrous will rust. I have done a lot of stainless projects over the years and you have to avoid contact with ferrous at all costs, especially on sanitary work. Cupronickel tubing works well. It does not rust and it is easy to form. The best SS to use would be 304L or 316L but hang onto your wallet and plan on purchasing some rather expensive tools to form the flares. If you do not have plans to show your car at Amelia Island or Pebble Beach, save some money and use the copper nickel alloy tubing.1 point

-

Stainless steel is more brittle and work hardens easier and it does rust. Not better on many fronts.1 point

-

There is no rational reason for having a plastic filter in proximity to the exhaust manifold. I don't even like having a metal filter in that location because it can absorb heat which is transferred to the fuel (vapor lock). There are locations that are much better suited for a filter.1 point

-

Are your rims actually rusty on the inside? Mine were pretty clean (original paint, too), so I just washed them and that's it. The tubeless tires use soapy water for mounting. Since we have tubes, I just used the good old tire talc powder. Both on the tube and inside the tire (spread it around with a piece of cloth, etc). Do not use organic baby powder for automotive tires 🤣 You don't have to worry about setting the bead, etc. Your biggest concern should be how to not pinch the tube in between the tire and the rim. Also, make sure that you have the correct-size tubes. One of my old tubes had a fold in it. When I put the tires on, I inflated them to around 10 psi, just to hold shape, and then pushed around the sidewall, on both sides, to make sure that the tube was nicely seated in the middle of the rim.1 point

-

1 point

-

1 point

-

1 point

-

I've heard a rumor that flathead replacement fuel pumps have a half-baked machined pin installed 🤔1 point

-

It’s good to learn with these old bombs. When you get that perfect double flare you’ll then realize that you forgot to put the nut on. Oops . I enjoy making up my own fuel and brake lines. I agree with Plymouthy Adam’s, you’ll have to reshape them anyway after unpacking them.1 point

-

That is a very reasonable answer. I have some smallblock dodge ARP rod bolts and just like the pontiac bolts, they also will not go into the 218 holes. I would appreciate your efforts in measuring your flathead rod bolts to compare numbers when you get the time. Thank you and anyone else who has early flathead dodge rods available to measure the rod bolts. This seems like a plausible answer. WELL AS A MATTER OF FACT: You are the man of the hour. I just went out to the garage with my nut/bolt gauge and also a 3/8-24 standard bolt with nut and amazingly so, they fit the Dodge rod hole, rod bolt, and nut exactly. Additionally, the pontiac and ARP bolt will not thread onto the nut/bolt gauge or the 3/8-24 bolt and nut. We have a winner!! Sorry, no chicken dinner. But many thanks for the solution. I never would have thought in that direction. Now it's a matter of if the rod and cap will take a reaming without interfering with the bearing. Thanks again for all the responses and especially the solution. It does seem odd that in all the builds online, no one mentions this. Thanks again all. dan...1 point

-

My 93 F250 rear shock upper mounts sit about 2 " inboard and below the frame rail. To install these on my truck would require mounting them on the inside of the C shaped frame, open side of the frame is on the inside so I would guess the standout to the shock stud to be about 4 inches. you'll have to wait till it stops raining and dries up a bit if you need more accurate measurements.1 point

-

1 point

-

The engine pictures are current, but it's not done under the hood. Planning on using a fuel block and hard lines. I set that up before I was able to find the right fittings to use on the hard lines. The filter is in a temporary position. As an update, I have been able to put some of the stainless on the strips that are on the glass. Slow going and hard on the hands.1 point

-

1 point

-

I agree with you that could happen, but only because it is a Pertronix. Points system won't do that because they fire on points opening. With the points open at rest there is no current flowing so it won't fire. Closed at rest there is current but the closed points don't interrupt the flow so spark. I have read that Pertronix fires on point closing, but have no personal experience with them.1 point

-

1 point

-

SURVIVOR: saw this Dodge between Lake Graham and Newcastle1 point

-

1 point

-

I have only installed a 2 piece flat windshield once, so I cant give specific advice, but I recall that multiple friends are a big asset to the task. Some pizza, cigars, beer, whatever you have to do to get some extra hands will be well worth it. Go slow and be patient, you can make it happen. Good luck!1 point

-

I consider points a switc0h. Open, close, on, off. Ignition switch on, ign switch off. Logic tells me my previous post is a possible scenario and every electrical circuit in the truck is available when the key is on.. I don't know whether or not Pertronix would or could respond similarly. How repeatable is this condition? Now that it's sat for a while will it do it before starting the engine or does it have to be run for a while. Will it do it after sitting for ten minutes or a half hour? Will it do it a second time, turning the key on and off immediately after it does it?1 point

-

I went to Tractor Supply this past weekend, for the second time in my life. That is all, carry on ship's work.1 point

-

1 point

-

Likely not a "factory" accesory, more likely a mass produced catalog or dealer option, these aren't listed in the Accesories section of the manuals.1 point

-

1 point

-

Mark does an excellent job explaining the inner working of the doors. Check it out. 1941 Plymouth Restoration (#13) The other videos in his series are also very well done. You can tell he was an educator.1 point

-

Thanks sniper and DJK for digging up info. And here's my two cents about electric pumps. First off, I love 'em! And here's why: When one of my vehicles has been sitting for a long time, I don't have to waste precious battery capacity cranking the motor to get fuel up to and in the carb. I also put a electric switch in the supply line to the pump so that, in Autumn when I'm putting cars to sleep, I can turn off the switch and keep running the motor until it dies. This does a good job of draining the carb, reducing varnish build-up. Yes, I could use a gas additive (and I often do), but with lots of cars and equipment, and full gas tanks in each, that's lots of Stabil! And, in regards to leaving the mechanical pump in the line, I've done that numerous times, but one thing to consider is this: if you do that and the rubber diaphram of the mechanical pump fails, you'll get raw gas going into your crankcase and diluting your oil... and not know it!1 point

-

The decline of the Champion Spark Plug and the death of a company. The Champion electrode was made from mainly tungsten powder at a company called Fansteel in North Chicago. They mixed, pressed, sintered, burnished and then brazed it to the copper sparkplug core before shipping them out to Champion for assembly. The company also made many other items like the Lynx golf club casting, High end tungsten darts (Black Widows & Diamond Backs) as well as supporting WW1 & WW2 military needs, they downsized in the late 80s and were dismantled early in the 90s along with VR Wesson a sister company that made carbide cutting tools. Fansteel Inc.docx1 point

-

1 point

.thumb.jpeg.28cb36506a6b17cd30e7d4a22504384d.jpeg)