Leaderboard

Popular Content

Showing content with the highest reputation on 09/03/2022 in all areas

-

75 years ago today, a red Plymouth convertible rolled off the line in Detroit. Delivered to Gettysburg Motors in Pennsylvania, it stayed in the same town until 2004 when I imported it to the UK. Still beautiful, but certainly no powder puff, last weekend it was put through its paces at Prescott Hill Climb.8 points

-

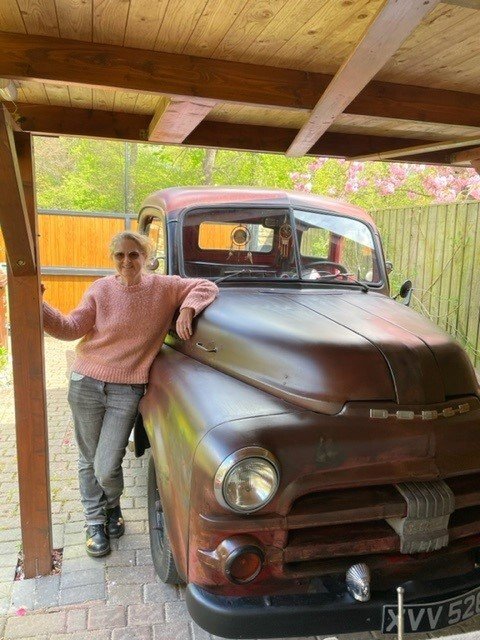

Hello all I hope I’m in the right place I see it says mid 30d and mopar I have a 1934 dodge coupe that’s been sitting since 1967 Motor was seized and it was dirty I spent a month and half getting parts for the motor did an in frame rebuild new rings main and rod bearings car runs and drives excellent it’s still amazing how a car sat for so long and runs and drives so well But hey it’s a Dodge I am not going to restore it I think it looks great the way it is! Thank you all John3 points

-

3 points

-

If the red part is actually part of the fuel gauge assembly I doubt it's show up in the schematics. Looks like a capacitor/condenser to me. Might be something someone added for noise purposes? So I looked up the part number, 1149325 I believe. Found an NOS one on EBay, no red thing on it. https://www.ebay.com/itm/3639065167882 points

-

2 points

-

Today I’ve taken my Chrysler on a road trip. A 250 mile trip. All hi-way driving in the interior of British Columbia. 2 lane non-divided hi-way. I took my thermostat out to experiment. The engine maintained between 150 and 160F at hi-way speeds. Ambient temps about 80F. Running a bit too cold probably. I’ve burned a bit more fuel than I expected. I suspect partially due to the cool engine operating temps. I am also thinking that my float is a touch low. . I engaged overdrive as soon as I left the driveway. Once in 3rd plus OD, I cruised at 60+ mph very comfortably. Not once did I downshift for any hills. It is plenty hilly around here, so that is impressive. The shocks and springs were noticeably good. A very nice ride. The hi-ways are also twisty in places. 55 mph was about the max comfortable speed I maintained on turns. Otherwise my skinny stock sized tires squeaked defiantly. 30 psi in them. They are radials that look like old bias tires. This was my longest out of town trip in my Chrysler. There is a big difference between my Plymouth and my Chrysler on longer hi-way trips. OD being the biggest factor. The Chrysler front steering feels a lot lighter. Not as good road feel. Maybe its the radials. My Plym has stock bias tires. Maybe I prefer the stiff road feel with the old leaf springs. Stiff tire sidewalls. Less lean maybe. My Chrysler has a more modern front steering geometry. Perhaps I need to tweak the sector gear a touch. I will look into later for sure. The 251 engine my Chrysler doesn’t feel any more powerful than the current 237 engine in my Plymouth. Could be due to power to power to weight ratios or the gear ratios. 4.11 in Plym. 3.93 (or something close) plus OD in my Chrysler. It definitely gets there faster though. As 60-65 is very comfortable. Not so in my Plym which really feels strung out at those speeds. A great day and a real nice opportunity to compare two 1938 Mopars. Some very different features and engineering in a few ways.2 points

-

A couple years ago I bought this lift a bit used and abused and rebuilt it right down to renewing the alignment turn tables and have used it a number of times but this is the first time I use the two rolling jack to lift a car at all four corners with the lift raised. I knew I would like this...I have made a few lifting devices to attach the arms to allow full use of the jacks....this lift required a light tweak on the mod as the factory has crammed a few thing in this space, panhard rod, shocks, traction bars, e-brake setup and exhaust prevented lifting with the axle tubes. Modified my V blocks with a cutout to allow lifting with the very heavy made factory traction bar mounts. The cutout prevents contact with the forward portion of the traction bar. This car getting renewed hydraulics and brakes all four corners plus clutch master and slave. Next up will hopefully be alignment of yet a different car.2 points

-

2 points

-

If you click on the three small squares in the upper right corner of the post you want to link and click share it'll give you teh direct link to teh post to copy and paste1 point

-

Hope you could find where I intended. Crazy link I thought would go to the correct page. It was on p14.1 point

-

You can angle the drift to focus the impact towards the outer rim to help avoid damage to the center area.1 point

-

Finally got the master cylinder off. Everything removed from under the car. Started using paint scrapers to get off the loose stuff and grease/dirt. Hate using sanding wheels on a grinder first and having it fling crap all over. Seems like the frame is in better shape than it looked, just surface rust. Also floor bottoms aren't too bad. Some kind of weird thick coating on the leaf springs. Scraped it off, loose in places.1 point

-

In SC mice can be a problem. I keep a bag of mothballs in the trunk and driver floor of the car. Keeps moths and mice away. You have to change them about once a year, and if you are working in/around the car make sure to air it out first with a fan. Will give you a headache, feels like a hangover next day.1 point

-

That sure sounds like fun! His car with the carrier on top looks like a great adventure!1 point

-

I knew I had his name spelled wrong......lol Your car looks good in the photo, sadly while the vinyl tops looked sharp they hid a multitude of sins and allowed rust to form and when actually would be visible, you in for some serious repairs, then add the flipper and the cure-all bondo...you get a bigger surprise a short time later. I think most of us sported slightly darker hair at that age.1 point

-

The lip must face inwards, as it seals the oil within the the axle housing. I believe what you are seeing in the post you linked is the outer metal housing of the seal that he was using. As for your seal driver, you may want to fabricate a flat plat on the end of it. A good seal driver is flat on the end to provide a solid surface to press against the seal body. By just using a pipe it is hard to spread the load out over the entire surface, especially when you can only strike your hammer on one spot around the perimeter. Most times when I don’t have the proper seal driver I use a blunt tool such as a brass drift, I also have some steel drifts. If have to use a punch I find one with a larger blunt end. I then use gentle taps with the hammer working around the perimeter of the seal until it’s seated.1 point

-

I have had better luck with modern replacement seals instead of NOS seals, a proper driver is critical.1 point

-

I got sick Thursday night and my work went on hold, but I did get back on the bicycle yesterday. These are the handlebars from the Huffy Sea Star 12” French princess bicycle (found in someone’s junk pile.) It’s Grinder Time. Tubing cutter keeps it square. These should “handle” the sissy bar. But more gussetry is needed before welding! A bit of metal from a broken wood lathe and a cardboard pattern. It’s gonna look very laid-back. I don’t know how it will ride yet.1 point

-

it doesn’t need to be a true seal, it was intended to keep dust out. the original was felt. i’ve run my truck at times without the bottom cover of the clutch housing. still has the remnants of the felt.1 point

-

I only know one other guy that trims the guides, the freewheeling Tony Smith. He's working on determining the best route to go for airflow in a flathead. As for the work, no more or less involved than porting and frankly doing one without the other is wasting time, imo.1 point

-

1 point

-

1 point

-

parts finally arrived and I have it ready to wax now....been a long time since I have taken this one to a crusie in....1 point

-

THIS ^^^^^^ When I left the SF Bay Area, both riding my motorcycle and driving (old and new cars) became exponentially more enjoyable.1 point

-

I’m out on a Sunday morning drive in my Plymouth today. Again looking for possible photo ops with period correct backdrops. Lately I’ve been reading the Grapes Of Wrath for the first time. Although it takes place before my ‘38 car was built, I feel I have more appreciation for travel in the 1930’s. People were tough. Cars also tough. Times were yet tougher. A great period of car evolution was in full swing. By contrast, today we watching a massive change in transportation. Perhaps the most complex automobile evolution since it’s inception. Electric vehicles. Momentum is growing. The change is in full swing. As the decades pass, the early days seem more attractive to me. I am fortunate to be able to relive them in my own limited ways with my 1938 Mopars. Perhaps yet an earlier period car is in my future….Maybe some day. Odometer 683 miles.1 point

-

What a day. Yesterday I cut grass to relax. Today's goal was to remove the pistons from the "woods car" block, and put the block and all spare parts in the old shed. As in normal mechanic work, one freaking piston had to be stubborn. Others were a little difficult, but one was extreme. Would not budge, so I finally took a very large coal chisel and broke the aluminum out around the piston pin, removed the rod, then was using a large brass punch underneath the crown. Was not stuck on the ridge at the top of the block, was at the bottom. Got to the oil rings and broke the aluminum around them. Nope, wouldn't move. I finally got my drill and drilled several holes in a circle underneath the piston crown. Then I knocked the middle of the crown out with a punch. Hoping to weaken it and relieve pressure on the rings. Tapped more on the remainder of the crown and the piston slowly came out. I tossed the rod for that cylinder. Banged it so much it had to be bent. Then I loaded the block on my dolly and pushed/pulled it to the shed. In soft sand. Did the same for the fluid drive, oil pan, head etc. Cleaned the garage up some and took off the trash to the dump. I am worn out. Did an 8 am to 3pm day. Can't hardly get around I'm so tired.1 point

-

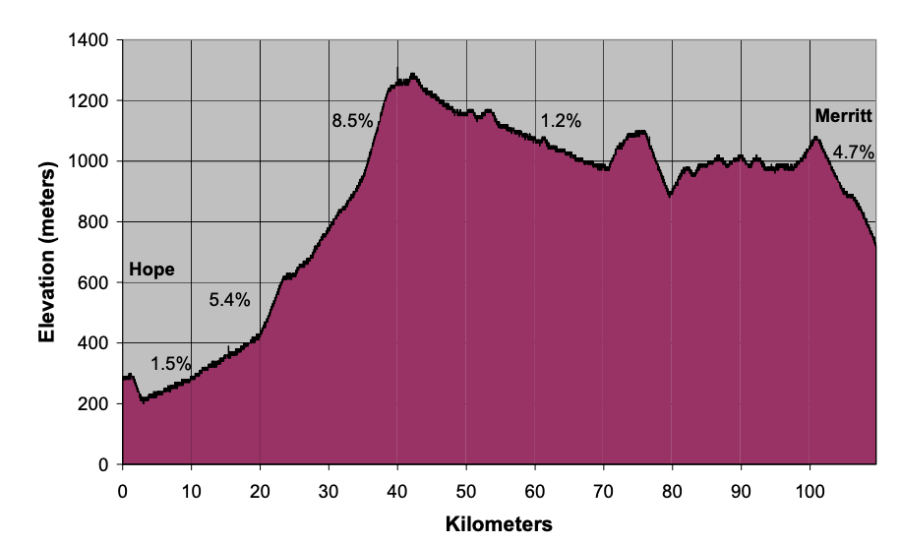

I enjoyed a nice trouble free trip. Just a tad under 300 miles total travel. I took a GPS along today check my speedometer and odometer. Seems I am traveling about 5% less than what my speedo reads. Not bad considering the car's age. I calculated my fuel economy. I am getting about 16.5 MPG with bias tires and my 237 ci engine. The car performed very well. I know my temp gauge is out about 15-20F. I took some caution today just to be safe. Heading back up a long mountain range home, there is a long grade. For many miles. It was a pretty warm day. Over a period of 20 mins I watched my gauge slowly creep up and up. The steepest section was yet to come. My temp gauge was pegged past the 212 mark. I would estimate I was actually under 200 still at that point. A profile of the hi-way home is shown. When I got to about the 800M elevation mark, I pulled over and shut the engine down. I waited until the temp gauge read 160F. I fired it up and without any trouble we climbed up and over the pass, maintaining 50 mph in 3rd gear. 1:1 tranny output and 4.11 rear end. The temp never did read higher than 210 (in reality probably 190F) all the way up. The car performed beyond my expectations. For my own peace-of-mind I may install a new accurate temperature gauge. Maybe bolt it down on the bottom edge of the dash. I pretty well maintained 50 MPH the entire trip. Glad I did the trip. I look forward to more. The engine oil level never moved. The car show was fun. Just one other old Mopar car. A 1937 Dodge, convertible. Pics seen below.1 point

-

1 point

-

1 point

-

My 52 B3B. My grandfather bought it on October 21, 1952 for $1,634.81 to use at his auto repair business. He told me when I was about 10 that it would be mine one day and I inherited it in 1975 with just under 48,000 miles on it. Work, kids, life, I just got around to the restoration thanks to the pandemic lock down. My goal was to put it back just like it was the day he got it. That's him at his shop in the early 60s.1 point

.thumb.jpeg.6ef7997bc12cdbc7a328734758328c5a.jpeg)

.jpeg.01888a0f2205eea29913e456668c7b91.jpeg)