Leaderboard

Popular Content

Showing content with the highest reputation on 02/09/2022 in all areas

-

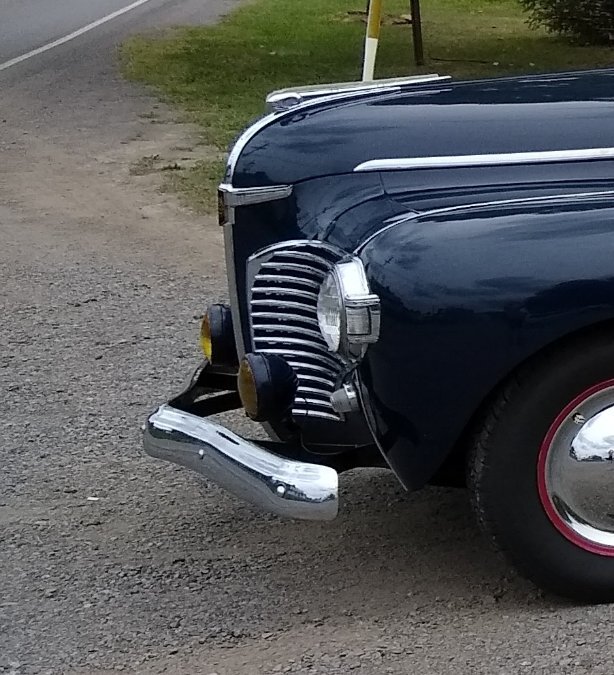

I have never really liked how far the front bumper sits ahead of the body on my 1941 Dodge Business Coupe. One of my winter projects this year was to make new bumper brackets and move the bumper closer to the body. I also like the cleaner look without the fog lights. Below are before and after pics.5 points

-

Tonight there was a small old 1938 Sedan in Canada that once again, propelled itself. I am tickled to share this brief clip tonight. One more has been checked off my bucket list. Many of ya’ll have experienced this. It sure feels good. A fresh new 237 engine. Now I just need to go find where I put the brakes. I seem to have forgotten to install them. No workee! ?4 points

-

4 points

-

Factory max recommended oil pressure is 50. Chrysler used to pull random flathead six engines off the line, mounted them in a water brake dynamometer and run them under load at 3600 rpm for 24 hours, as part of their quality control procedures. My car was running 3280 rpm at 65 indicated on the speedo which showed as 62 on the GPS. When I had the engine at the machine shop, I asked the fellow what his recommendation for sustainable cruising rpm. He said for long stroke engines that was 80 to 85% of peak hp rpm, assuming good operating conditions regarding engine temp, oil pressure, and oil quantity and condition. My rpm at 60 to 65 fell within the 85% brackets. He also said that exceeding 4000 rpm for more than a couple minutes without modifying oil supply to crank and cam could result in expensive noises. Use the calculator for your specifics and operate accordingly. Our car has the 4:11 rear, before the od was installed, we did several 500 plus mile trips at 3300 rpm sustained with no problems. But checking the oil level at every fuel stop was part of the routine. This after the re build.3 points

-

When first breaking your engine in it’s good to have the car pull at close to full throttle to maybe 45-50 MPH and then take your foot off the gas and coast down to 25-30 MPH. Repeat many times. This sucks the rings out to the cylinder walls and really helps them seat well. The first few hundred miles are very important. I had the 260 V8 in my ‘63 Ford ? Fairlane 500 rebuilt last year and was told again by the rebuilder that’s the best way to seat rings. I was reasonably gentle the first 500 miles until I changed oil. Now I drive it a little harder than I used to. Lots of ring seating advice on You Tube. I liked the one on “piston ring break-in 101”, I think by Luke Shaw. He stresses the engine needs to be worked and not over-babied initially. However your car, your choice. Have fun!3 points

-

Lol, you like to live dangerously. I use 10w30 detergent oil. Others use what they like.2 points

-

2 points

-

Lee Petty said his 49 P17 could do 92 mph. He used Imperial wheels, tires, shocks and springs. The Imperial tires were very large diameter so he changed the final drive gears to 4.3. We worked it out that little 218 must have been turning 5,200 rpm! Which must have been really flogging it. But then he only had to do it for 500 miles. Peak output is listed as 3,600 rpm so…. Maybe that’s why he got torn down 15 out of 19 races. Enzo Ferrari loved his race cars and he didn’t put much effort into his street cars even though they paid the bills. So you don’t see many Ferraris at the supermarket. The reason is the cars he spent his time perfecting only had to last 24 hours. The typical “licensed” Ferrari was lucky to make it to its first or second tune up before major work. Lee Petty’s P17 I am certain was pushed beyond all reasonable limits. So kids, don’t try this at home! I would think a redline at or near 3,600 rpm is good unless you do some serious work to the engine.2 points

-

Tonight I took it beyond my driveway for the first road drive. I stuck around the neighbourhood. Hilly up and down terrain. Baby-ing the motor. I pulled a few short hills. Through all the gears. No lugging and no high revs. First impressions: Torque! More torque. I can feel it right off idle its right there. Also pulling turns and on the hills too. In 2nd and 3rd, I feel quite bit more torque. It's quite pleasant. And smooth! Oh boy is it ever a smooth running engine. Like creamy butter is applied when the toque comes on, up the hill. Early indications are this 237 in a P6 is going to be quite a nice little package for me. I look forward to completing the full break-in period so I can work it hard up the big hill home. My testing ground. I topped up the master cylinder and the brakes are back.2 points

-

2 points

-

maybe it was optional but both my Luxury Liners, 41 Sedan, 41 Business coupe and the spare bumpers on hand all have filler panels between the body and the bumper..1 point

-

Back to the max rpm— I have seen these engines make 5k if allowed to breath. My biggest concern is cylinder ridges on later life engines. If the engine spent any amount of time at lower rpm’s, cylinder bores most likely are worn there, stretching rpm’s may allow a few extra thousands above the ridge, potential cause for ring failure. If ran in at high rpm’s from the start, think they are capable. Question is— where you feel comfortable.1 point

-

before taking any action on the oil pressure issue (question), I'd confirm with an independent gauge. I wouldn't assume the original is accurate.1 point

-

For a small block Chevy maybe and as a MINIMUM. Heck the factory recommended oil pressures are above that guideline anyway. IIRC, the Mopar Perfomance engine book called for less pressure than 10 psi per 1000 rpm, but I'll be darned if I can recall the exact amount anymore. I;m not even recalling where the book is that has the info anymore. lol Not all engines are the same. The flathead has two sets of oil control rings, the SBC one set. The timing chain on the flathead is twice as wide as the SBC as another example. One cannot automatically assume that what limitations a specific design has is applicable across the spectrum of all engines. Lots of variables, but if you are seeing that kind of pressure with a thick oil, change viscosity.1 point

-

1 point

-

1 point

-

Not sure why you think 60 psi is dangerously high, it isn't. If you have Facebook search out The Freewheeling Tony Smith and read up on his oil system work.1 point

-

These long stroke engines were originally designed for torque with minimal transmission shifting. My understanding is back in the day it was considered luxury quality to be able to drive around in only 1 or 2 gears. The less shifting the better the car. So torque was king. Not necessarily top end speed for the average car owner. The old square cars plowed through wind resistance best they could. Air flow design had not been considered until the early 30's. Soon after the Chrysler Airflow was released. The flat head six in mass production by the early 1930's, there became less demand for the 4 cylinders engines. Henry Ford even had to relent eventually. The Mopar flathead 6 saw little change until it was replaced by the V8 in about 1954. Compression numbers rose over the decades, stroke changed and grew bit. The basic foundations of the engine design, still the same since the 19-teens. High revving, was not part of the design for these mass produced people movers.1 point

-

My speedometer was like that when I first picked it up. A drop or two of CLP oil in the gauge side of the cable and it has been smooth and quiet ever since. A nice 'No tools required' job. Your milage may vary Keep in mind that max safe rpm when the car was fresh off the showroom floor, and max rpm when 70+years old are likely to be different. Wear, loose parts, tired fasteners, sludge, deposit build up, state of the carb and distributor. You have good oil pressure on your engine. How's the compression? Have you adjusted the valves? Is the oil pan full of sludge? Does it smoke? Rattle? Does the distributor vac advance work, or suck air?1 point

-

a few years ago, my nephew helped me put the cab back on my b3b, he asked “where do the air bags go?” Oh to be 20 again…. ??1 point

-

Thats a really good question. A few factors and you can chart up with your tire size and gear ratio and mph. But your ears know when when your pushing it. 3600 is max. 2800-3000 should be your sweet spot. Buy a Westach for 140.1 point

-

You can buy oil specifically designed for breaking in engines. I got mine at Auto Plus when breaking in the rebuilt engine in my 1951 Dodge D39 business coupe. I put 500 miles on it and then used 10W-40 for next 2000 miles. No need to change more often than that in my opinion. I never took it over 50MPH for the first 500 miles and then drove it however I wanted. I certainly didn’t baby it.1 point

-

I recall seeing a factory test horsepower/torque curve that went up to maybe 4000 or 4200 RPM. Power dropped off pretty dramatically after 3600 RPM (RPM for max horsepower). Personally, I'd rather not abuse my nearly 90 year old engine that much.1 point

-

Thanks for the kind words folks. I am 99% sure I know what’s wrong with my brakes. They have been sitting with no residual pressure at the wheel cylinders, for the past 15 months. They have been dripping down. Not uncommon for old cylinders that the owner hones, scrubs with scotch brite and re-uses. They’ll seal up and stay dry when used. Park it for a few months, then they start self bleeding. Despite my reluctance, I am going to install SAE30 oil tonight. Initially I put in 10W30 for first start-up. I’ve flushed it through the engine for probably 30 minutes by now. I’ll dump it now. Then proceed to break-in the rings with SAE30. 100 miles or so later I’ll dump the SAE30 and go back to 10W30. Someone has convinced me the SAE30 is the right oil to break-in the engine. I am skeptical but what the heck. I’ll do it. Won’t hurt anything. For my fellow Canadians, Princess auto stocks it. Easy to get.1 point

-

Many years ago, I was changing the oil on my first Mopar, a 75 Dart SE with a slant six. Took 12 quarts of oil to hit the full mark on the dipstick. Being a relative noob about cars back then I thought something was wrong, but wasn't 100% sure so I stopped and waited till the neighbor guy who was into cars got home from work. After we confirmed with the Dodge dealer that it should take 5 quarts not 12 and being told that a new dipstick and tube were not available we ended up getting a universal dipstick. We put in 4 quarts, marked the dipstick for low then added one more and marked it for full.1 point

-

Ordered some stainless tubing to make a dipstick tube. In the pack were various sizes, the smallest one was like a string. Could actually blow thru it . Ignore the oatmeal remains in the bowl. Mini Tubing 3.mp41 point

-

1 point

-

1 point

-

all jokes aside, no chance of going through the ice. it was 18" thick. we put about 6 to 8 of the blocks under the ice where they are being loaded, which helps with buoyancy around the "opening" and the loaded truck or trailer.1 point

-

1 point

-

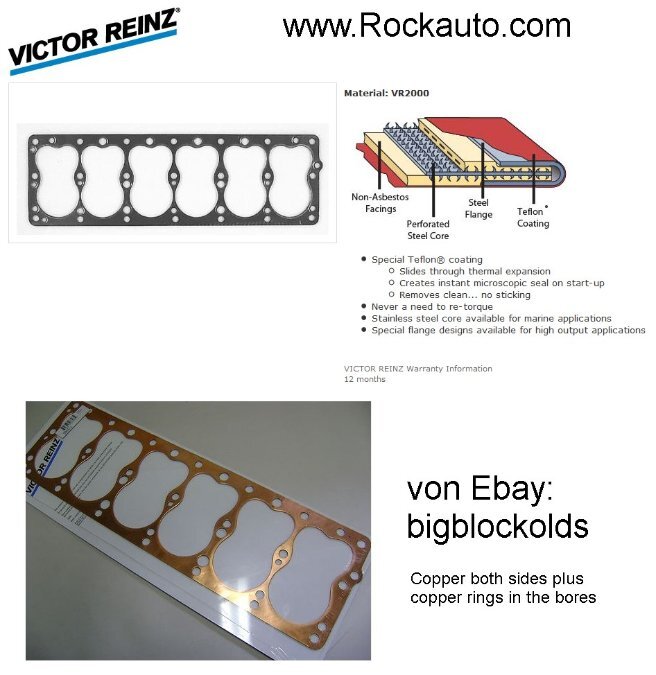

The gasket is not symmetrical, so You cannot turn wrong side up- if not obstructing needed holes! Remember the order of tightening the bolts, following a helix (see last pic) in several steps! And You must follow the torque instruction (see Service Manual) with a torque wrench. Under-the-tree shop practice is not recommendable any more. Dont forget to add antifreese to the water- it must protect for corrosion too. I can´t find the right one now, antifreese comes in different styles. Sealant or not is more a question of belief- I prefer not to put it because of the risk of overdoing (and getting some in the holes!) and the mess when having to scarpe it off when removing it. Good gaskets of today don´t need sealant. Greetings from Düsseldorf! Go1 point

-

blocks were sticking to the bed (another remnant of friday's storm), so each had to be "loosened" before being unloaded all manual labor at this end. that's a workout just lifting the block about 4 inches onto the ramp. good crowd, too. lots of kids, plenty of smiling faces. went back for another partial load. got 13 blocks, but lost 6 when exiting the lake (there's a pretty good double bump exiting the lake, and moderately steep). however, the 2-speed came into it, and started shifting on this trip, so the driving was easier. ended up with 73 blocks into the icehouse this year. some will still be there next year when we harvest again.1 point

-

1 point

-

1 point

-

There was an "ice house" in the small town where I attended high school in Ohio. It was on a remote side street. It had been in service for several years but by the mid 60's it was not making money. This (doomed) Ice House (still using harvested ice packed in sawdust) started selling beer. In a last ditch effort to stay in business they did not fully check ages of the customers. What is a high schooler to do:confused:1 point

-

Here's what I was talking about. Here's one of Wally's pictures adjusted to "back in the day"... Here's the link to the web site... http://labs.wanokoto.jp/olds Once there, click "English" in the upper right corner.1 point

KLKL.jpg.059feb8a98dbc2aa6e8aabd24c7f020c.jpg)