Leaderboard

Popular Content

Showing content with the highest reputation on 01/15/2022 in all areas

-

7 points

-

When I dive deep into a hobby, I almost become obsessed with it. Digging in to find as much info as I can. I hunt for an on-line home for my hobby. The best place for support specific to my chosen passion. I found P15-D24 while seeking out options in a Google search. This site is without a doubt, the world-wide home for flathead era Mopars. I am a Facebook user too. I am a member of many FB groups specific to flathead era Mopars. I certainly don't learn much there on FB. I don't feel connected with any FB group members. Here we seem to have friendly, caring people who want to help. The age demographic here lends to respect and kindness. I have recommended this site countless times to FB users in specialized Mopar groups. I cannot tell you for sure how many come here, then register and stay. I have a suspicion that some users in here have different profile names on FB. So we can't really tell who's who between here and FB. I agree that the FB user interface is terrible. Yet it does help feed my seemingly endless desire to feed on flathead Mopar era information. However, indeed here at P15-D24 it feels more like home. @2nd place would be the AACA forum. I like it there too.2 points

-

2 points

-

1 point

-

It is the number of the mold that casting was made from. It is for QA purposes, so that if there is an issue they can narrow the iffy mold down quickly. When casting heads the foundry will use a number of molds to facilitate mass production of the castings. They have to be able to track what casting came from which mold, the -# does that for them. It is not the number of revisions to the mold, as some say. If the mold is revised the part gets a new casting number. The final machining will set the part number.1 point

-

It's nice to see a youngster interested in those old vehicles Looking forward to hearing that engine run!1 point

-

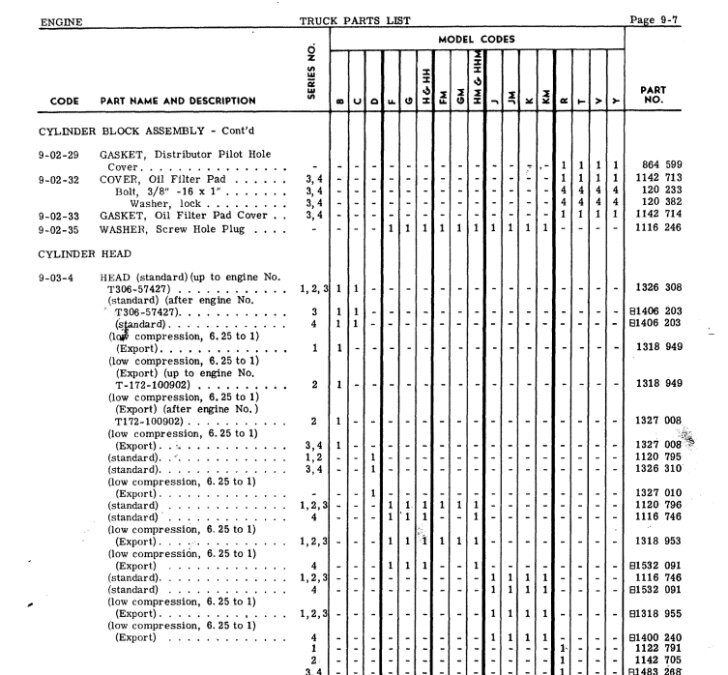

Interesting theory, Greg. It got me thinking, so I took a look at my parts catalog. In the B-series trucks, the 1/2 and 3/4 ton (B & C) trucks got the 218 and the 1 ton (D) got the 230. I see that indeed the 218 and 230 engines have different head part numbers. (Serial number break is likely for internal vs. external bypass) But it seems they also had a low compression head available for export models. I wonder if the car side did the same thing.1 point

-

Installed the 19" Derale fan. Huge difference! Much quieter and moves more air than the fan that came with the radiator. As a side note, I found the Derale fan on ebay for $52.00. Seller said it rattled when turning, so he had never installed it. Since these fans are usually North of $150.00, I took a chance. Turned out that the spring washer on the shift had been installed backwards, once I turned it around and installed it correctly, it ran quiet and smooth as silk. Score one up for Wes! Wes1 point

-

In order to get an accurate reading, you need something like a piece of plexiglass to keep the surface tension of the liquid from throwing off the reading. I used a grease to seal the Plexi to the head. Alternatively you could use a non water based modeling clay or 'silly putty' to press into the chamber. Once you have it to shape and leveled across the top, pull it out and drop it into a graduated cylinder that has a known amount of liquid already in it and note the change. Ie if your measuring cup has 50cc in it. You drop your chamber mold in and the level rises to 150cc, you have a 100cc chamber. My work may have some scratched up Plexi they are throwing out, I will see if I can nab any. Bryan, did either of your heads have a date code cast in?1 point

-

I did this as well. Two bottles of Marvel in all cylinders and changed oil. I’ll see if I can pull the valve covers and take a look. To my knowledge, a stuck valve would still create some kind of backfire through the exhaust. I’m going to check the intake and exhaust manifold for a blockage. However, oil does get pushed out the exhaust a little bit and the carb sucks, so the exhaust-end is probably good too. It’s just so odd. The starter was fine before I pushed it back into the flywheel gears, engine is free and lubricated, put fuel in the carb, air is sucked in, WAS a new battery. I just don’t understand. Timing and cables HAVE to be it. It’s a fairly simple machine. I hear that the oil pump and/or distributor cap can be inadvertently turned the wrong way, - messing up the timing. Fuel very well may be burning wayy after the compression stroke. Maybe this is why it’s sluggish to crank? (Combustion at the wrong time giving the engine and starter resistance?) I’m 22, so I don’t have a huge understanding of these old-timers1 point

-

1 point

-

Sweet! Nice solution. Must of been a little tricky figuring out getting those standoffs in just the right positions before welding? Do the oem hubcaps fit well and go on and off easily? I'd like to do the same on my 39 Plymouth's rear rims which I had custom width wheels made by the Wheelsmith. I'm now running a smoothie cap which looks OK, but would be better if I could use my oem Plymouth hubcaps.1 point

-

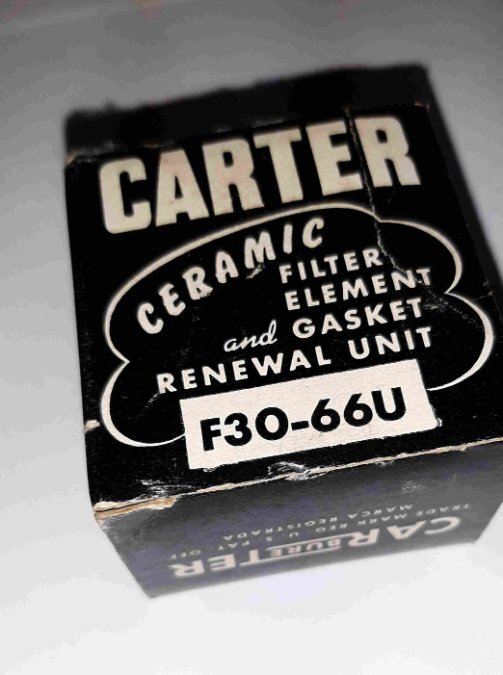

The ceramic filters are pricey...kinda hard to find with gasket...they certainly will last as long as you can drive a fire truck. I've had the the same ceramic filters in my 4 tonner for over 30 years. The NAPA ones Young Ed shows will be just fine too...in fact I just ordered a couple for another truck engine.1 point

-

1 point

-

I forgot to mention one good test. Do a voltage drop measurement on the starter cable while cranking. That will confirm if you have a cable issue that is hidden or a battery that isn't holding up during cranking.1 point

-

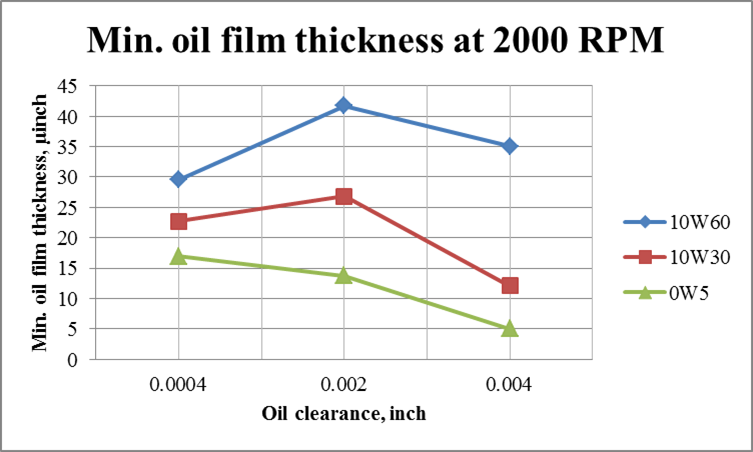

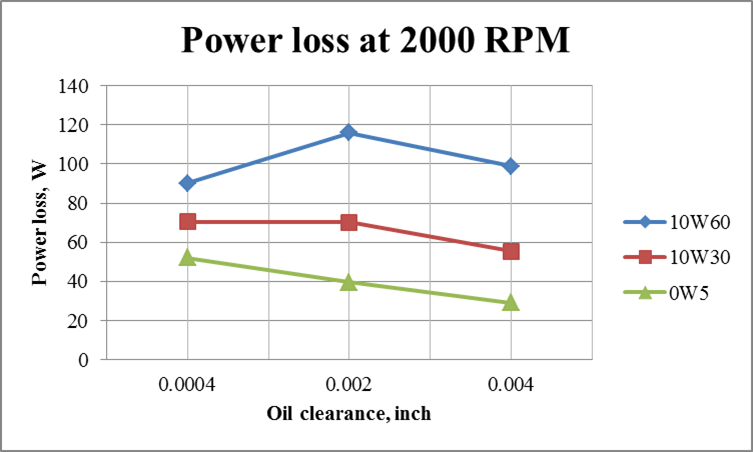

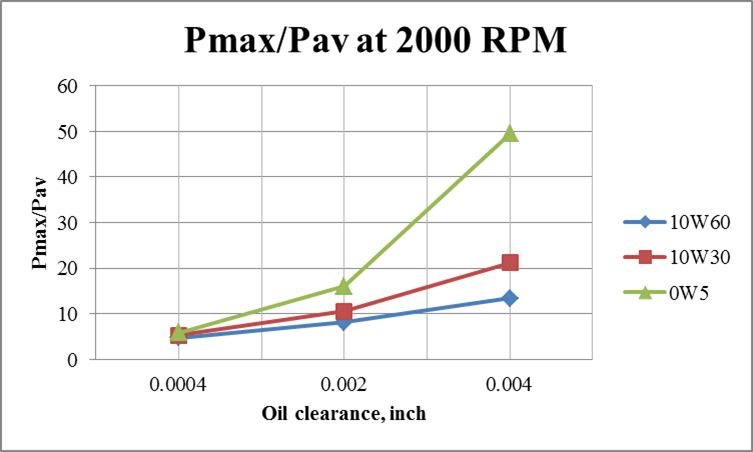

All this discussion about viscosity and break-in in the end have to do with oil thickness coating at various RPMs. Found this really technical paper online that relates oil film thickness, power loss, oil pressure to viscosity at differing rpms I haven't really digested it all, but it should inform this discussion. https://www.substech.com/dokuwiki/doku.php?id=effect_of_oil_viscosity_on_hydrodynamic_friction_of_engine_bearings1 point

-

Interesting question! First, I've worked in the software industry since the early 1980s, (yes last century) My personal opinion is Facebook has the worse user interface I have ever seen and for something like a question/answer forum it is worthless. That's why I license a commercial forum software. I think the trend of many sites to move to Facebook is financial because it is basically "free". No license fees, hosting fees, security certificates etc. But the experience basically sucks. From an admin point of view the forum software in way ahead of what I can do on a social media platform. I have a p15-d24 Facebook account, primarily so members can use those credentials for registration and login if they want. Really haven't focused much on posting on Facebook just do to time constraints. At some point I will look at making it more active, primarily as a"recruiting" activity back to this site.1 point

-

Omg..."Rob-Rated"....how did I miss that??? This is why I'm friends with you. You remind me I was in the 5th grade once. Thanks brother ?1 point

-

Try reading thru this thread for help searching, it is more towards searching on the computer full site version vs. cellphone version. https://p15-d24.com/topic/46048-search-help/1 point