Leaderboard

Popular Content

Showing content with the highest reputation on 07/31/2021 in all areas

-

"stock trans is busy with rpm".... What I mean is running my three different stock trans, at around 55mph, the engine is running at alot of rpm, around 3000 rpm best I can remember. With the 5 speed, I run around 2000rpm at 55 or so. Where I live, it is hilly, and some open roads. Lower gears are great on steep driveways, and some of my friends live in some difficult places. Much of my driving is on 55 and 60 speed limits. So the TK5 works great for where I live.2 points

-

2 points

-

A thermostat is a valve. It opens and closes automatically. Either allowing coolant to flow from the block to and through the rad. Or not. A cold engine runs inefficient and makes more sludge in the crankcase. Rough running too. The sooner everything gets hot,(operating temperature) the better. When the engine is cold the thermostat stays closed, so the block coolant cannot circulate through the radiator. This allows the block to get hot quickly. When the coolant temperature reaches the thermostat rated temperature, it begins to open. The 160 thermostat opens sooner than the 180. Then the rad takes over and does its job cooling everything as much as it can (within its limitations). If its 100F outside either thermostat stays wide open. The rad cools as best it can. At this point it makes no difference what temperature rated thermostat you have. Both thermostats are wide open and trying the cool everything down. However when its cold outside, maybe the cold air flowing across the rad is cooling the block down too much. We get little heat from the car heater. The engine is not hot enough. Its not burning efficiently again. The 160 thermostat will close and remain closed. Allowing the block to run upto to 160F. Then the thermostat will open, allowing coolant flow to the rad, cooling again. The block cools down. It may get too cool, the ‘stat shuts off flow again. The cycle repeats over and over as the thermostat tries to maintain 160F coolant temperature. The thermostat could also be named a regulator, as this is exactly what it’s doing. Indeed a 180F thermostat may be better in the winter. If its quite cold out. Keeping the block and coolant a little warmer. Trying to maintain 180. You may be cozier in the cab. The car enjoys better, cleaner engine fuel burn efficiency. If you are cruising along, 50 mph on a flat section of road, it’s -20F outside. The engine is not working hard. Its not making much heat. The thermostat may be closed. A 200F rated ‘stat if possible, might seem a better choice. The rushing cold air, you still may not get enough heat in the cab. The block just can’t get hot enough. Then we try blocking the rad with a piece of cardboard. That helps! Removing a thermostat for better cooling? Many did it back in the day. They did not understand the principles of operation. Old wives tales. Back in the day before social media. You are actually causing premature wear on engine parts by removing a thermostat. The engine takes longer to warm up.2 points

-

2 points

-

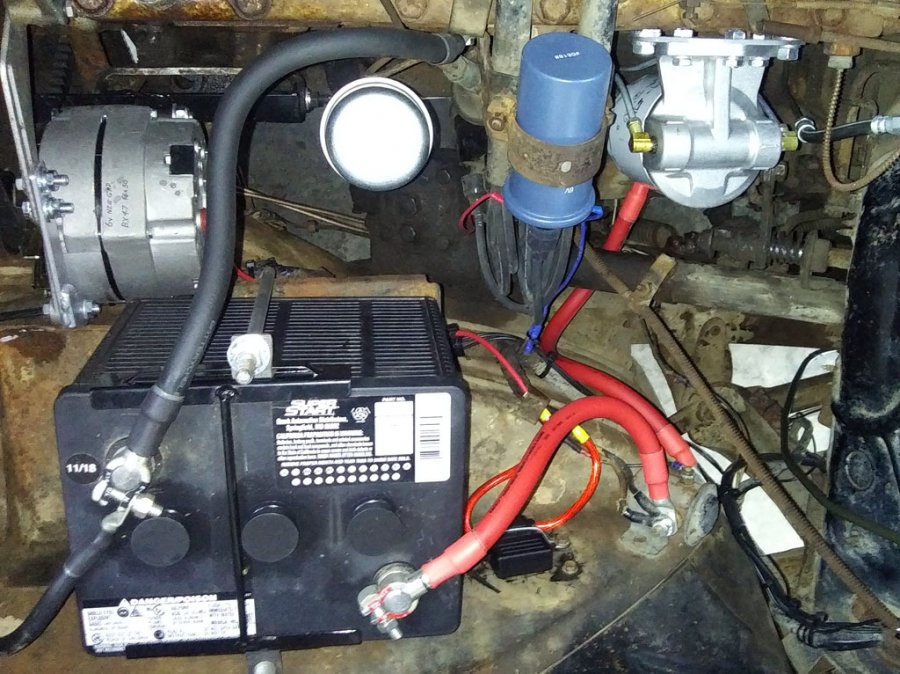

Maybe I'm just lucky but I've never seen a hint of parasitic drain with my single-wire 6v alternator and I never use a charger. Even in the winter, pull the choke, hit the starter and it fires almost instantly (I do have an electric fuel pump, however). I suspect one reason this is the case is that the alternator keeps the battery fully charged even at idle. I've had the P15 sit undriven for three weeks or so and have never been able to tell the starter was lagging. If someone wants to retain the generator, that is fine. But some of the above comments about drain, wiring complexity, difficulty in sourcing, etc, just haven't been applicable in my installation. The alternator has been completely transparent in operation, headlights always bright, starter spinning quickly.....and the ancient regulator (tried twice to get a new one that worked...) in the scrap box. It's good to have options. ?2 points

-

You’re a braver man than I am! Also, I have never seen that option before……..on any car. I see from the packaging that it is a genuine Mopar product. Very interesting and thanks for posting.2 points

-

1 point

-

Looking good. I'm glad the MC bracket worked out, one less thing off your list to worry about1 point

-

The start to open temp is usually where the thermostat is labeled. So 160. But remember, thermodynamics and the understanding of how engines operate has increased tremendously since our cars were built. Today;s engines can last over 150k miles with simple maintenance. Ours were lucky to hit 100k, usually much less. A lot of it had to do with machining processes, material choices and lubricant improvements. But don't forget moisture in the oil is harmful no matter when the engine was built. All that sludge found in old engines? Too cool thermostats helped put it there. Lots of SAE papers on this issue out there.1 point

-

I believe that is a 160. I think the thermostat rating is when it will start opening. Someone correct me if I'm wrong.1 point

-

As a postscript , after those few months of time pass with the truck sitting and in your possession, you may consider the mental transition away from rational roi to hobby/passion where the costs up to now are sunk costs and become fuzzier like fish stories become greater, and you look at it as a hobby whose costs invariably are irrelevant, and complete has lots of positive and fond memories of your sister and boyfriend, and one day those will be important and this debacle will be a footnote. To boot, it will also have some nominal pretty decent resale value, and you will enjoy it thoroughly. The fact is you have a very solid and complete (in terms of pieces) truck and it’s on its way to being a very nice daily driver. If you can afford it, plow forward with rose colored glasses, and join us in this forum, start a build thread, and the peanut gallery will join you on your journey, and maybe meet you at the annual picnic in California.1 point

-

While the service manual doesn't say to use one or the other specifically, pg 69 in the plymouth manual tells about the uses of each. The first paragraph gives the impression that 160 is the norm and the 180 is for colder climates to help with the heaters. Joe Lee1 point

-

The Studebaker engine was designed by the same group of engineers. It does look very similar but I don't believe anything interchanges.1 point

-

Military spec Dodge 230. Pricing may be a good deal if it's in good shape, as in ready to run.1 point

-

How old are you? ? I’m 72 and still have a decent memory but don’t remember those….but maybe I am actually forgetting. ? What I do remember were those wonderful air pumps/gauges like the ones pictured below. I think the last time I used one at a SERVICE station was probably about 30 years ago. They were accurate, quick, and FREE. Sometimes progress is not always for the best. Good ones sure go for big money nowadays at swap meets. I even like the old bricks in the second picture.1 point

-

1 point

-

That wiring scheme will certainly work even though there is a redundant connection. The wire from the alternator directly to the battery isn't necessary since the same connection is being made at the 'Bat' junction on the old regulator. The regulator can be removed if those three wires are simply tied together.1 point

-

With the Gyromatic it’s important to keep your carb and distributor especially if you find an engine from a different application. You just need a good short block. All of the ancillary components can be taken from the original engine.1 point

-

Now that is something modern trucks could use. Factory puts them in with the stem up, facing the bottom of the bed and no one ever checks them.1 point

-

Going to agree to disagree here. I like the stock gear spread and with an OD it would be pretty close to perfect. I mean the TK5's 2nd gear is almost as low as the stock 1st gear and you think the stock trans is busy with rpm? Maybe I am not understanding what you mean by that. Anyway that's what makes the country a wonderful place, you can be happy with the TK5 and I can be happy with something else and no one is upset.1 point

-

Comes from the same thinking that gave us nitrogen in tires. Racers do it therefore I must do it. Without considering why racers do it and what their perceived benefit is.1 point

-

1 point

-

It wouldn't take a competent auto-electric shop long to repair your generator. I'll bet you could have it fixed and back on the car in less time than it takes to: figure out what 6-vt alternator to use; find it; buy it; 'drop it in' (as if?); and sort out the wiring. How much driving are you going to do while the generator is in the shop? A fully charged battery will start the car multiple times and run your ignition, signals, brake lights and so on for hundreds of miles. If you need to use the head and tail lights in a pinch, they will do OK... dimmer than usual and your spark intensity will be down, but the vehicle will be functional. Top up the charge every night and you're set. Maybe this is the time to replace your old battery with a shiny new one using some of the money you saved by not buying an alternator. Your old battery can live in the trunk for the time being with a pair of booster cables 'just in case'.1 point

-

I installed a 6v Howard Enterprises alternator in my P15 and it has been flawless. https://www.ebay.com/str/HowardEnt?_trksid=p2047675.l2563 The price is very reasonable since they don't charge extra for shipping. It is a one-wire, internally regulated alternator so you can either remove the regulator or leave it in place as a terminal connection. Just one connection to the battery terminal or lead on the regulator is all that is required. I removed the regulator since I never intend to return to the generator and installed a 60a fuse in its place. I fabbed my own bracket but Howard's universal bracket set will save you some time.1 point

-

I used this modern cv boot on mine, just cut it down. The nice thing about it is you just slip it right on as it is split. I used hose clamps to secure it and it comes with tiny bolts that stitch it shut across the split seam. I have put a few thousand miles on them and they are still holding up. I tried those new reproduction leather boots and they shredded. And I dont want to use the new old stock rubber boots as they are super difficult to put on and heard they also fail. Here is the exact one I used: https://www.oreillyauto.com/detail/c/dorman-help/cv-driveshaft-axle-16804/cv-boot-12852/246d80e5eb6e/dorman-help-cv-joint-boot-kit/mtm0/03609 I cut and trimmed it about halfway into the third rib. I would recommend putting it on first and figure out exactly where you would cut it for your application. They even have them in stock at the store.1 point

-

I know I'm not considered part of the "Posse" in any photos. Side note though, CO isn't a bad stopping point between CA, WI, and MN......1 point

-

A couple of interesting things here from these photos from April (3 months ago). This has turned into a complete restomod rather than just enhancement. The owner should have appropriately informed you, or rather given you appropriate estimates and expectations. It's looks to be only about 1/3 complete (that's I guess the 20k out of my estimated 60k full restomod), unfortunately, though possibly the fitting of the engine and trans was majority of the work, there is quite a bit of work to be done but not impossible, and you would have a very nice truck afterwards, except @Frank Elder may never talk to you though he might join the posse forming (he gets a bit annoyed at putting "cheby" engines in Mopars). This mechanic definitely is not the only one who could do the work, but it would take someone who has done complete end to end builds before to do it efficiently. You don't have to take them to court, but you have to sound convincing and assertive so he takes it seriously. In the end, the work looks quality-ish so far*, but the expectations on what you want vs what he thinks you want or knows how to do are totally off. He's way down the road of restomod, and going back now is pretty much gone. There are folks on this forum who have done similar and could give better estimates. My original numbers above presumed back to original with few mods. This is like an episode of Texas Metal; just be careful it doesn't come out lowered 12 inches. On the positive side, now that the running gear is "modern", then most any mechanic would know how to work on it, and hook everything up, so your options are greater. Instead of looking for a restoration shop (though they are still good), you can tell them you have a truck that half-way through a Chevy 350 restomod, but needs to be "finished". Summary: Given the state of the truck, you are likely $20k away from a good daily driver truck. a) You could sell this one for probably $7k in its current state (parts alone), and let someone else finish it. You could buy something (or nothing) else. b) You could Finish it yourself in your spare time c) Have this guy bring it to some state like running d) have another shop do the work that you trust and can supervise. A good shop that focuses on it could knock it out in a couple of weeks, but rest assured you are in the middle of a complete restoration. If that's not what you bargained for, or negotiated, then you may seriously consider suing, but lots of other custom shops can finish this truck for you. You can also take your pick of personalities on Motor trend network; I'd go with Stacey David though I think Garage Squad would be more appropriate here. ? Observations: 1. He's got a 1950 or so Chevy truck behind this one; I think He's turning your Dodge into that one. more interesting and relevant: 2. The engine is in place and mounted, and presumably so is the transmission. It looks like this GM 350 just by looks but they all kind of look the same *Is my imagination, or is that engine and cab sitting too far back? That front cross member should be underneath the engine 3. Front suspension and steering changed completely -- rack-and-pinion now. No steering wheel shaft so steering not yet connected. 4. Not clear from these pictures what's going on with the drive shaft or the rear end, but the rear wheel hubs are the same as the front wheel hubs, so I think the rear axle was also changed out. Did he mention 4-wheel disc brakes? 5. Not seeing a lot of wiring - so on the todo list 6. whole front end fascia needs to be put back together and wired up. 7. rear truck bed and wiring needs to be put back together 8. Not seeing any brake lines - need master cylinder probably too 9. not seeing any fuel lines - probably never fired up 10. Need exhaust, cat, muffler 11. A/C needs to be connected as well as heat 12. Linkage for transmission 13. Interior - totally needs doing - that's quite a bit of work (what happened to the old one?) 14. Did I mention wiring, lights, etc? 15. Giving away/getting rid of a complete engine/trans/steering/diffs for the truck is a shame. That alone would be worth at least $1000 sold to many of us on this forum. 16. No Carburetor - need to buy one 17. No radiator/cooling system Questions to get current status on and expected work in regards to: For each, what has been done, what remains aa) What's the minimal work required for the vehicle to move/stop under its own power a) Wiring: sub-a) 6v to 12v conversion b) Fuel system c) Brakes d) Front suspension e) Rear Suspension f) Rear Differential/Axle g) Engine sub-g) Engine management, fuel injection 2) Is the engine placed appropriately to keep proportions? h) Transmission, Transmission linkage I) Drive shaft J) Front Fascia K) Interior seats, dash L) Steering M) Fuel system N) A/C O) Heating P) Bed/Running Boards Q) Doors/Windows/Windshield wipers R) Cooling system S) Overall Look - The truck should look original with original proportions bb) What the heck took 3 years? Would love a timeline of this work. It's like anything, can you come to amicable terms with this person, or is it better to break up, because you are in a broken relationship with this mechanic. I listed about 20 items (incomplete list), consider (generously) if each item took 1 day for one skilled mechanic, then a build would take approximately one month in total, and each day costs $560 labor/day + ~$500 in parts (that's a generous underestimate), then remaining build is approximately $21k. Yeah... that's why they call it a "passion".1 point

-

My opinion, worth little: that old overdrive, to me, is a lot more fun than rowing a 5 speed. Something about lifting that foot and having it shift...1 point

-

1 point

-

1 point

-

You can get it at Aircraft Spruce. https://www.aircraftspruce.com/catalog/appages/cat.php1 point

-

Thank you Ralph, I appreciate that. I've known for awhile I would be paying more than I wanted to, but never in a million years did I imagine it would be in exchange for nothing. I bought it with a small inheritance from my sister. Wherever she is, I bet she is sad too.0 points