Leaderboard

Popular Content

Showing content with the highest reputation on 12/17/2020 in all areas

-

3 points

-

Having fun making these silly videos...Hope the next generation clings on to these old cars. They sure are fun and unique.2 points

-

Just having mine done now. For my old style ball and trunnion drive shaft joints on the '41, I ordered two kits from Andy B (to do both ends) $205 including shipping to AZ. Of course if you have to replace one or two housings, that would add to the cost. If you need housings, shop around. There are some on Ebay and others. My u-joint housings were fine, no wear; I had replaced one worn housing when I took them apart to inspect them about 5,000 miles ago. I too had some recent vibration above 45 mph or so, so while I have the tranny out I decided to have the shaft balanced and rebuilt in case that was a contributor to the vibration. Having new pins pressed in and the shaft balancing is going to cost another $100 or so. The kits do come with Boot and clamps. The rubber boots are a little bit of a struggle to install through the housings, but with some lube and patience it certainly can be done. I have done it and it's not too bad at all. Here is a link that does a good job explaining the process. Hope it helps. https://www.classiccarrestorationclub.com/video/how-to-rebuild-a-ball-and-trunnion-drive-shaft-008786/2 points

-

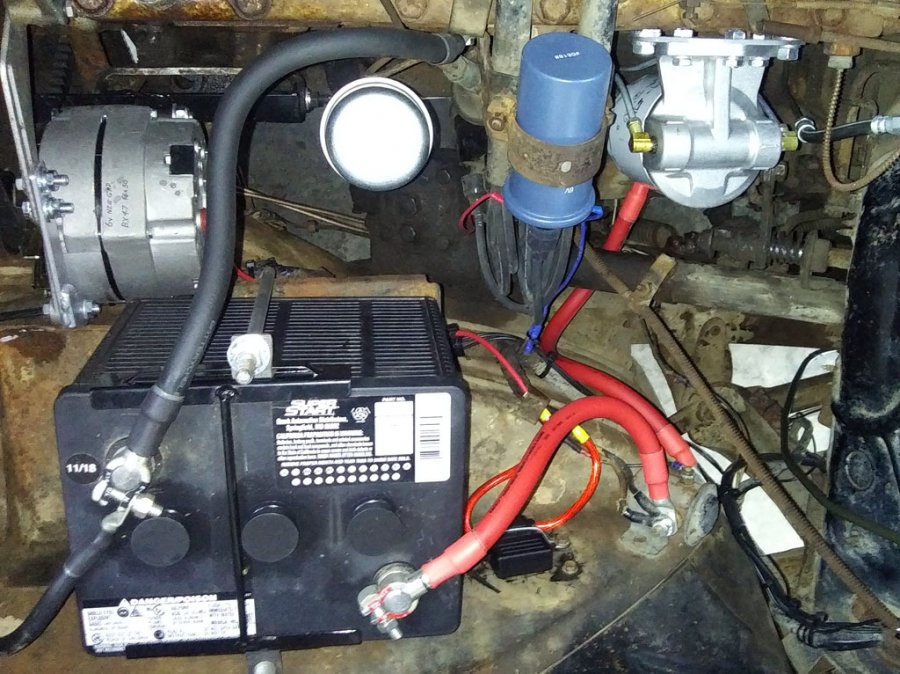

Here is the 6v system in my '48 P-15. It spins as well as any older 12v vehicle I've had and has never failed to start. The key components are fresh, properly-sized battery, starter and ground cables, and the 6v alternator which keeps the battery hot all the time. Here is the vendor where I sourced the alternator: https://www.ebay.com/str/HowardEnt?_trksid=p2047675.l2563 It is internally regulated so one wire is all that needs to be connected, the old regulator gets tossed. Battery cables: https://www.batterycablesusa.com/1-0-gauge-battery-cables-0-awg.html Provided the starter and ignition is in good shape there is no reason why a 6v system shouldn't start your car reliably.2 points

-

Flange yoke: https://www.dennysdriveshaft.com/p2471_dana_spicer_2_2_349_dodge_flange_yoke_replacement_for_old_de.html Driveshaft I ordered with the slip yoke: https://www.dennysdriveshaft.com/p9619_1310_series_3_inch_with_spline_and_slip_driveshaft_for_chevy.html My driveshaft ended up being 59 3/4 inches and Dennys wanted to upgrade me to a 3.5 inch tube. After I spoke with them and explained the HP and Torque the driveshaft would be transmitting, they agreed to stay with the 3 inch tube.1 point

-

There was a thread a year or so ago (which I can't find) where I posted a shopping list for the parts needed to build a driveshaft for our cars that is a bolt-in replacement. The necessary adapters are available that bolt to the flanges on the transmission and diff, a seamless conversion. Seems the total cost was somewhere around $400.1 point

-

Sounds about right. It just makes you THINK you have a lot of money if you have 17 grand floating around in your wallet these days. The reality is it buys very little,and what it does buy is junk mostlhy made in China by slave labor.1 point

-

1 point

-

I wasted a lot of money trying to stay with the original. My new u joint shaft is perfect.1 point

-

1 point

-

I remember working on some Link Belt excavators 'back in the day' that had a 12/24 volt system All of the electrical system was 12 volt, with a 12 volt alternator, but the starter was 24 volt. It had 2 - 12 volt batteries with a fancy series-parallel relay/switch in between them. It would connect the batteries in parallel under normal conditions for 12 volts, but when you pressed the start switch it would switch to series connection to give 24 volt to the starter motor. It worked well, but it was weird to work on.1 point

-

I changed my 47 to a 12v to start but everything else is still 6v positive ground. It required 2 batteries. I had to do it that way because I have a fluid drive coupled to an m5 transmission and I didn't know what 12v would do to those expensive and hard to find solenoids and other stuff. Rube Goldberg would've been proud. I don't know if I'm going to keep it that way but it makes the it easier to start until I can get it on the road and run the motor in a little bit. Also, I used a 56 Dodge starter that is 12v but has a gear that is compatible with the tooth count on the flywheel. (144 teeth or something like that) The next year they upped the tooth count to 177 so a later starter won't work. Some have suggested that although the 6v started works fine on 12v, binding and failure to disengage can happen. Anyway, good luck1 point

-

1 point

-

I converted my 51 to 12v last year. Battery, alternator, regulator and bulbs where all I had to change. I emulated the charging system of an 87 Diplomat in my case. http://www.yourolddad.com/12-volt-conversion Napa was able to give me 12v versions of my 6v bulbs, just took them in and they set me up. I did put in a 12v heater blower motor mostly because my original 6v one was not useable. http://www.yourolddad.com/blower-motor Wipers were a whole 'nother deal and I ended up fabbing up a current limiting circuit to slow them down, not 100% satisfied with it though, seems to be too slow for a one speed setup. The speed I have would be perfect for a slow speed setting on a two speed setup. Still mulling over what to do here.1 point

-

I would make sure you have extra thick battery cables if you haven't done that yet. Helps cranking on 6v a ton. I have seen people use 8v to get a little more oomph during cranking but that is known to be hard on lights and electronics. I am a little biased towards 6v just because I like the stock configuration and I'm not entirely sure what the 12v conversion constitutes of.1 point

-

Sorry I don't know the gas milage. I really don't want to know either. Its purely driven for pleasure. Knowing my gas milage seems like a way to screw up the pleasure part of cruising about in a big old flathead powered car! lol.1 point

-

I found myself engulfed in looking into my archives of old MoPar literature today. Came across this internal memo sent to Dealerships and thought I would share it. With a bit of luck the opening note can be read... It was printed on yellow paper with brown ink! I would be thrilled to find any of the mentioned items under my tree this year! Enjoy.1 point

-

1 point

-

Got it! Started from scratch, drove car, brake pedal got firmer and firmer, brake lights stayed on, put car up on 4 jackstands, all 4 wheels really dragging, sucked juice from master cylinder, took a 1/32 drill bit and stuck it into tiny drain back hole, fluid shot up about a foot! All wheels free, I remember blowing out the two holes while rebuilding the master cylinder, but I probably just jammed more crap into it...when I let car back down, it just about rolled out of the barn by itself...thanks to all the assist....now to deal with loose steering and moderate death wobble....1 point

-

1 point

-

I've done friction welding making custom CV axle shafts in the past (weird stuff like Artic cat ATV insides and Bombardier ATV outsides......) I also do quite a bit of friction drilling - also known as flow drilling. We make thin walled manifolds at work and the flow drill gives enough material that a 12ga steel tube can have NPT threads. Another cool technique I have tried in the past is thermite welding. I helped repair a piece of cast for a traction engine and did it the "way it would have been done" when the engine was in use.1 point

-

Many years ago I working the booth at a trade show and the company next to us did explosive welding. Didn't think much about it until I started looking at the samples on the table (It was a really slow show) and a sample of aluminum welded to bronze caught my eye. Wait a minute, how did you do that? He explained the process and and noted production days were a lot of fun with all the explosions! Customers were mostly military contractors who needed weird hybrid materials.1 point

-

1 point

-

1 point

-

0 points