Leaderboard

Popular Content

Showing content with the highest reputation on 08/04/2020 in all areas

-

These engines are in a very soft state of tune for the most part. It does not take a super hot spark to keep them happy. The real benefit of using a module like this is fewer moving parts... avoiding sub par points and condensers...and the inside of the distributor cap and rotor stay much cleaner. This is why I converted mine.....and it never fails to start and run right. Day in...day out. Jeff2 points

-

I dug out my 1942 Dyke's manual to see if there was any mention of pulling thermostats in the summer. There were good instructions printed. Every spring and every fall the cooling system was to be flushed out to remove rust and scale. (white scale is a result of using hard water in the system) Alcohol, or sometimes another type of anti-freeze, was added in the winter. Alcohol would have been another expense I suppose, not needed in the summer. Cars often needed water topped off as it boiled and steamed off. I remember all the old service stations when I was a kid had air and water readily available. For free! There was no mention of removing thermostats in the summer months. I suppose many folks just did it because they didn't know any better. The spoken word is a very powerful communication method. The thermostat idea may have been just spoken word and passed along. If enough people did it, and talked about it, it must be the right thing to do? People did not have computers in their pocket to look things up. Still to this day, there are lots and lots of folks who can't tell you what a thermostat is. Open a modern car, some engines are encased in shields. The only serviceable piece is the twisty-cap-y-thingy that has the numbers "710" on it. In some ways the more things progress, the more things stay the same.2 points

-

The front spring is the clutch fork return spring....2nd picture... the rear hanging spring in your picture is the E -brake pull back spring which on a 4 door or coupe also connects to a 10" extension link rod (approx.) hooked into a small hole in the floor brace. 1st picture shown is the E-Brake return spring with out the extension link...1948 Chrysler convertible X frame shown. Does not use the extension link.2 points

-

I often question some of the things that were possibly common practice in days gone by. Like what you just mentioned concerning thermostats, or my old man telling me my grandfather would build a small fire under the oil pan of their car in the winter to warm up the oil....not sure to this day if he was full of sh#@ or not. I know my grandmother wasn't joking when she told me her alcoholic father would drop them off at church on Sundays (in the 1920s) and then go to the bar. Then he wouldn't pick them up, they'd walk home. Not everything that was done in the old days was right, that's for damn sure. I'd never remove the thermostat from my 51 in any weather.2 points

-

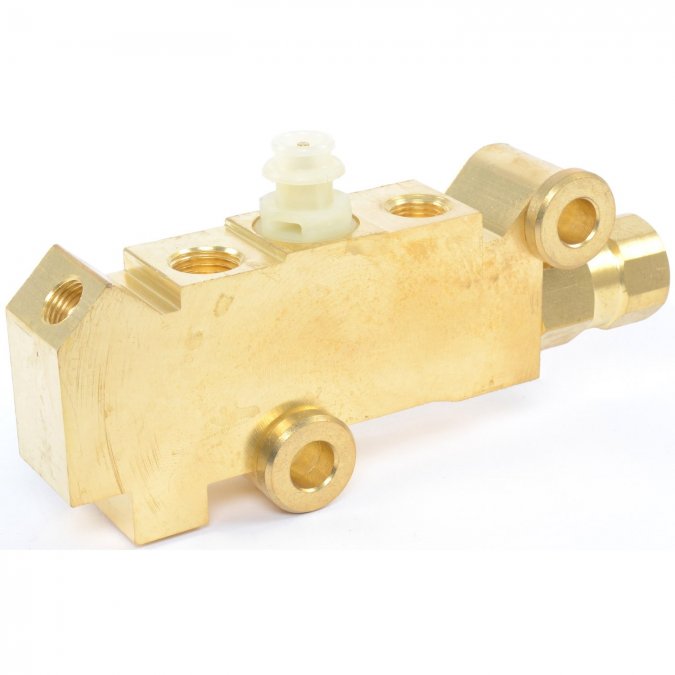

I’ll look into that valve. I’m keeping the stock mc and the stock rear axle and brakes. All hard lines are new nickel copper and the rubber hoses are new. I have two reasons for this conversion. I average 3500 miles a year with my car in sw PA where hills are a way of life. Even my driveway is a hill. I also haul my grandkids a lot so any safety upgrade is a plus. I think I have it figured out on paper, we’ll see how it works. Thanks for the advice.2 points

-

New Member: 1936 Plymouth 2 Door Sedan I just picked up this 36 2 door sedan, I believe it is a touring sedan P2? Original inside (I've been told) , 1 repaint many years ago on the outside,. It is said to have original 50k miles. Runs good, low RPM knock. Starts fine. Smoke bad on de-acceleration. I love it...Need to learn about these MOPARS as I've been a Shoebox fan for years... Bill j. "Tierod"1 point

-

I would start by pulling light bulbs, I imagine if tail lights are 1157 you have 12 volt neg ground.1 point

-

Agreed, the amount of heat energy lost through the radiator is the same no matter the speed since it's a recirculating system. The net amount of time coolant is in the block or the radiator is the same no matter the speed. Restrictors cause the pump to make a little pressure in the block...eliminating steam pockets (cavities) and thus keeping it from pushing coolant out the overflow due to that expansion.1 point

-

Check the battery terminals, coil connections, and ammeter connections for a clue to what may have been done for polarity.1 point

-

Look at it this way, the longer water is in the radiator to cool, the longer water is in the block to heat up. Almost always, if there is a heat transfer issue with regards to high water flow, it is due to cavitation, which is probably what was going on with the Ford flathead mentioned.1 point

-

What a great find. I love seeing these old gems like this that have survived and are still pretty much original. I bought a '36 Plymouth rumble seat coupe in 1956 for $25.00 but foolishly sold it later. Mine was black like your car is. Keep it and enjoy it. John R1 point

-

yeah...that could work...but you often get caught returning to the scene of the crime....1 point

-

Simplest way to find out is to drive back by in the daylight and see what you swiped 'em from..1 point

-

1 point

-

for the cost of any test...one would probably be best advised to just take the system down for a reseal...if the prior fluids caused reaction....the only real peace of mind here is to flush and start anew....1 point

-

1 point

-

AHHHH, I wondered about that when i took it apart, but thats the way it came out so i put it back the same, I'll swap those around and see what happens. Thanks AA1 point

-

Is it a 6 volt alternator, or has the truck been converted to 12 volt? If 6 volt it could be either, and I don't know how to tell the difference. If it is 12 volt it is likely negative ground.1 point

-

there is no need to run a thermostat if you wish...but if you pull it, you need to install a restrictor plate that is equivalent to opening of the thermostat...this is to control the exchange rate of the water in and out of the block.....many folks overlook the total purpose of the t-stat1 point

-

Yep, sounds right. Except the hotter spark...a hotter coil doesn't necessarily mean a hotter spark. All those recommendations should be read as, or greater. The module isn't all that special, it does one thing; break contact when the coil needs to fire. It's a switch, with current limitations. The current runs through it and that's the limiting factor. If reliability is the main concern then a higher resistance is better. Why run the module at it's limits. I see no need to run 60kv coil. As far as I know you aren't running spark quenchingly high 11:1+ compression or anything like that. In fact, you likely won't ever even actually see a 40kv discharge....or even close. The coil is going to fire at whatever the minimum voltage is to ionize the plug gap. That increases with plug gap, rich mixtures, high compression, extreme temperature etc. With 40kv on one of these low compression low rpm beasts you can run your plug gap out to probably .065 and be great and still probably not pushing the coils limits. ( Btw without a plug gap change your spark will not see a voltage increase no matter the coil, just current) So your 1.5 is probably as well suited as anything else as long as it can handle full voltage all day. So for me, slap in a 1.5 flame thrower coil w no ballast. Set the gap at .045 on plugs. Call it a day. Rest easy knowing I'm not pushing the limits of any component of the system.1 point

-

As an aside, a proportioning valve only handles on part of what you need to combine a disc and drum brake setup. The combination valve should handle all aspects of making a disc/drum combo play well together. The combination valve does the following. Proportioning, which the aftermarket proportioning valve will do as well and is the only thing it does. Hold off, which will delay pressure to the discs until a small amount builds in the drums and this only happens once the shoes touch the drum. This allows both the disc and drums to apply simultaneously keeping one end from locking up or applying with nothing at the other end potentially causing a loss of control. Then there is hinge point, modern self energizing brakes (which most of our stock ones are NOT) are not linear in their application and use leverage to apply the brakes even harder. Hinge point drops the rate of rear brake pressure increase to keep the rears from locking up in a hard stop. Finally, there is the pressure differential switch, which is what turns on the BRAKES light telling you that you lost pressure in one of the two circuits. An attentive drive will probably notice his brakes are not working right, but the average driver needs a warning something is amiss. When I converted my 65 Cuda to disc/drum I used the cop spec Dodge Diplomat braking system, including the factory combination valve. I figured the factory sorted it well so I'd just copy. Works very well. But the problem with combination valves is that they can be very braking system design specific. I know, for example, that in my cop brake swap there were two possible combination valves used, the difference in the braking system is that one valve was used if it had 10" rear drums, the other for the 11" drums.1 point

-

On my 47, disc front and 8 3/4 rear end I used a valve for the front (6) and a second (8)for the rear also used a rebuilt stock MC with 7/8 bore. Stops perfect. With a stock rear end very important you get the shoes adjusted to spec. good Luck1 point

-

1 point

-

When it rains, it pours, lol. Thanks for the pics Dodgeb4ya. it'll help me too.1 point

-

1 point

-

ya might want to snake a stiff wire in that axle housing drain to see if any sludge is piled up in there...but more than likely the differential leaked out of that old crusty leather pinion seal, judging by the dribbling evidence in that area...1 point

-

1 point

-

Beautiful car!! I’m slowly learning how my 40 Chrysler ticks....enjoy1 point

-

Sounds like you're keeping the stock master cylinder as I did. Is your rear axle stock or??? I removed the internal check valve from the stock master cylinder and did not install any residual pressure valves or proportioning valve to see how well it functioned. That was years ago and never had the need to install any other items. I am running modern 10x2 drum brakes in the rear and a Rusty Hope disc brake kit. Since your stock master cylinder has 2 outlets, consider installing a combination valve if you want added safety. It wont help if your master cylinder fails but it will help if you blow a line between the valve and the front or rear brakes. Most come with residual pressure valve built in too.1 point

-

I got the Fargo home today after 20 years or so in storage, I bought it in the mid '80s as a project for me and my Dad (he was a garage mechanic and Mopar man) just a few minor things, needs the rear end finished up, brake line and or horn. Not sure what the engine is, it was a rebuilt back in the day, and My Dad and I rebuilt it in the early '90s after a frost plug fell out and it over heated. I had lots of adventures with it, it once was my daily driver, loved it, cruising speed of 45, I have had it up to a mile a minute a few times, felt like the end of the world! Model, FM2 - 2 6 Thankyou for having me!1 point

-

1 point

-

Seems clear enough, "Ignitor II ignition can be used in conjunction with most ignition coils rated at 0.45 ohms or greater" I installed Pertronix ignitions on several air-cooled VW's and left the Bosch blue coils in place with no problems.1 point

-

Crazy, I reread your initial post and I believe you said you did NOT remove the head? Only thing I can think of is some crud was blocking that hole and it got dislodged? I suppose you could pull the head, tap the hole and use a shallow pipe plug well sealed to close it up. Just make sure it sits below the deck so teh head will set down properly. Might be an opportunity to mill the head some for a boost in compression, trying to find a silver lining for you here.1 point

-

After market motorhome would be my guess. Just glitter for that new vehcicle you really will not get enough use of to justify the expense, unfortunately few do. DJ1 point

-

Definitely aftermarket simulators. The 6 lug pattern is interesting. Maybe for an Iveco, Isuzu, or similar type of Asian style delivery truck.1 point

-

Great car, looks straight, complete, and unmolested. It appears to be a P2 - bright sergeant stripes on the headlamp stanchions, wood grain trim around the windows and on glove boxes (one fake ha ha), two wipers, should have brown rubber starter pedal pad and other rubber interior parts. These are wonderful drivers as they are small, steering is light, and the hydraulic brakes are adequate for a 2700 lb. car. Mechanical parts are available, although some are '36 only as this was a one year only body/chassis. Trim parts are expensive and somewhat had to find. The only change I made to my unrestored P2 coupe was a replacement L230 '58 Dodge flathead engine for the blown 201. It runs like a small V8. You've made a good choice.1 point

-

Using Ford flathead data for anything other than a ford flathead is only useful in the most general sense, the Ford's intake and exhaust tracts are way different and one could argue substantially less efficient that the Mopar flathead. The way the exhaust ports are routed through the block is what gave Fords the rep for overheating. A lot of the exhaust heat was dumped into the cooling system. Now your comments on the crank makes sense, but I think that it would be three pairs with the timing 120 degrees rather than 180, 360/3 is 120, with a cylinder firing every 120 degrees adn all 6 would fire after 720 degrees of crankshaft rotation. I thin the best bang for the buck would be a modern piston adn rig design with a shorter piston, using longer rods and a three ring pack using much thinner rings. Lots of mechanical friction to be removed and while the lesser bob weight would help higher rpm (not where we want to go as you mentioned) but it will help it rev faster too. I love these kinds of skull sessions.1 point

-

1 point

-

heaters were generally installed by the dealer. Cars without heaters have the holes stamped but not punched through. about all that you can do is make up a metal plate which will cover the hole.1 point

-

1 point

-

I ordered a small 2 stone hone from the internet that arrived broken, while I will get my money back, this puts me in a bad position on my timeline on the little car. So I borrowed one from my neighbor, something I really do not like doing. Long story short his was laying helter-skelter in tool cabinet drawer, one was damaged from use or storage I have no clue. I try to keep mine protected...so in returning his to him it wall also be protected. Just an idea to pass along to those out there who may wish to do similar. Use an old prescription bottle, a multi-step bit if you have one and drill to match the body of the tool. Stones are protected from accidental chips.1 point