Leaderboard

Popular Content

Showing content with the highest reputation on 12/06/2019 in all areas

-

3 points

-

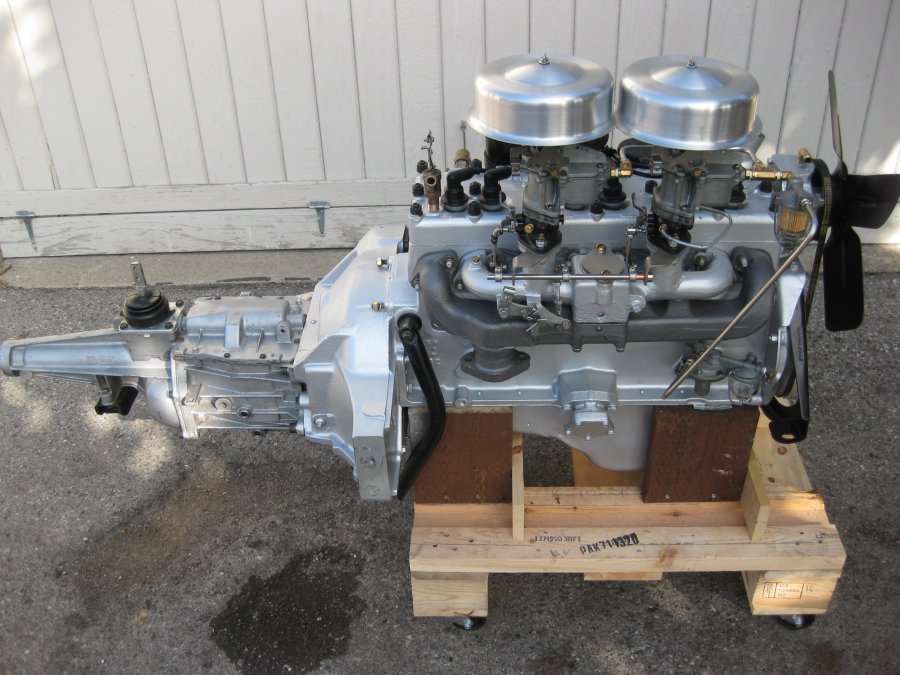

I boxed the frame and added a M II style front suspension, front mounted power R & P disc brakes, coil over shocks. Doing it this way, all the sheet metal bolts right back on, stock wheel track width can be maintained and I can set the ride height where I want it. Maybe it's more a matter of where you want or are comfortable doing your fabrication. Most of these frame swaps are also going to have some sort of powertrain swap involved as well. I can't imagine too many of these S10 swaps will have the factory flathead and trans going back in and if you want Mopar powertrain, you probably won't find a lot of aftermarket support for using it in a S10 chassis.2 points

-

2 points

-

1 point

-

Do not try to yank the wheel off by pulling on the steering wheel rim! You will be sad when you destroy the wheel...... Yes, you need a puller. Read the threads about pulling the steering wheel to get the big picture of the process. If you are fortunate the wheel will pop off the shaft once you start persuading it with the puller. I used a generic puller like this: https://www.ebay.com/itm/Lisle-45500-Harmonic-Balancer-Puller/352774075278?epid=9028573416&hash=item5222f9338e:g:avAAAOSwxMNdazxy Instead of putting the pointy end of the puller into the steering shaft, drop a bolt into the shaft so the puller can push against the bolt head instead of damaging the threaded end of the shaft.1 point

-

in the absence of the C612 tool....often folks use a harmonic balancer puller....1 point

-

Nice ride! The Deluxe is much more rare than the Custom trim level. Enjoy!1 point

-

My phone's camera has a sneaky way of making my car look nice. It's not nice. It's super rusty. This morning when we took it out things were frozen solid, and road salt is at a minimum right now. So I don't worry about it much. If my car was rust free like my 48 B1D, I wouldn't drive it at all in winter.1 point

-

Point file. They used to be available in every parts store. hastings was one vendor i recall.1 point

-

I forgot to mention the trick to filing contact points is to clamp both contacts onto the the filing tool at the same time so that the edges are worked parallel...then clean the contacts with rubbing alcolhol on a cotton swab or the like...1 point

-

Dec. 6, 2019: Drove my daughter to Cabin Coffee so she could get a "turtle frappe". She texted me from inside and said some old guys (everyone is old when you're 14) liked my car and wondered why it wasn't put away for the winter. She came back out with her coffee before I could finish my return text. My battery was down a bit for whatever reason so the generator was working hard. It leveled out after a while. Heater worked good. I need to take it for a longer cruise! ?1 point

-

I heard that at one time there was a small flat file that could be used to clean the contacts and that should be done periodically...also heard that an emory board could be used as a substitute...1 point

-

You have to call Tom to order the correct bases. A lot of his stuff isn't on the website. That said, he's been downsizing the business in recent years, so no telling what's in store1 point

-

I dug up the shock absorbers that I pulled off of the '49 1-ton to study them a little more, as they appeared original with the DPCD logo stamped into the dirt shield. I was able to get the p#s off of them and critical dimensions: F -- 1261982 -- 12.38 -- 20.25 R -- 1196294 -- 11.75 -- 18.75 I could not find neither of these p#s in the parts book nor could I find any reference to them online, so I'm not sure if these were original to the truck or if the p# I'm looking at on the dirt shield is referencing something else...these dims compare very close to the dims of the 31000 & 32207 shocks that I've been using for years from Monroe, which were listed as replacements in their interchange book back in the 90s. So I did some studying of the parts manual and Monroe's Instruction Guide, as well as Gabriel's Online Catalog (which took some digging to find), and found some more part replacement numbers that could be used. Some shocks are more available than others, and some shocks are cheaper than others, but after putting a few more hours into researching this topic, I think we have more options available for builds and restorations. One thing I noticed in the parts manual is the specification of 1" domestic and 1-3/8" heavy duty export. Looking at the shocks available, the common spec for passenger cars is 1-3/16" bore, with light truck shocks having a 1-3/8" bore. I switched to a large bore shock on The Blue Bomber years ago, and it produced a slightly bouncy ride unladen but under a heavy load or pulling a trailer, the truck rode nice and smooth, and braking was much more controlled, with noticeably less nose dive. So if you are just going to use your old buggy for commuting, then the 1-3/16" shocks should work fine, as they are a stronger design than the originals...if you plan on carrying a load on a regular basis, then the bigger shocks are a good investment. I know when I was hauling water with both my '48 1/2 ton and '49 1-ton, I noticed after a few years that the replacement shocks (1-3/16" bore) were all leaking as I was really loading up the suspension but not moving in a hurry on any trip nor traveling tens of thousands of miles annually. B-1-B, -C, -D B-2-B, -C, -D Front -- Monroe 31000 = Monroe 59001 = Monroe 32293 Gabriel 81147 = Gabriel 82047 [1-3/8"] -- Monroe 34904 - Monroe 37098 - Monroe 37112 Gabriel 61500 - Gabriel G63689 Rear -- Monroe 32207 = Monroe 59017 Gabriel 81676 - Gabriel 82007 [1-3/8"] -- Monroe 555004 Gabriel 61550 = Gabriel G63949 - Gabriel G63299 B-3-B, -C, -D B-4-B, -C, -D Front & Rear [1-3/8"] -- Monroe 66858 - Gabriel 82065 The Monroe and Gabriel shocks are not exactly the same in extended and collapsed dimensions, but they are generally within 1/4" of each other. The best way I can explain this is that the Pilot-House trucks have a certain suspension travel, as do other makes & models that have similar geometry, and the manufacturers make shocks that fall within a certain range within that travel, so several different shocks could possibly fit a certain suspension geometry and still work. I would favor a shock that allows the spring to hit its bumpstop so that the shock is not bearing a severe load...conversely, a shock should still have some stroke left when the springs have reached max vertical travel so that the tires are not being lifted off of the ground prematurely, enabling more control of the vehicle in extreme situations. Obviously, the B-3 and B-4 shocks that are available now are more limited...just looking at the applications online, that 11/16" mounting diameter does not appear to be an industry standard as the 5/8" and 3/4" mounting diameters have been used on many shock configurations over the years. I would list the different colors that these shocks are coated, but some of the factory descriptions do not match the pictures on their websites...also, some vendors had different colors listed from the factory website, so I reckon ya get what you get in the box1 point

-

One reason is there is a bolt In kit to do the s10 swap. early s-10 frames left a lot to be desired in weld quality, had a 4wd that broke a front diff housing. What happened was control arm brackets were pulling away from frame. personally if i was doing a swap, my preference would be a dakota chassis,to keep it all mopar do like how this is going though.1 point

-

Well I guess this topic might have gotten your attention. As some of you might know there were several major mechanics tool companies during the 1950's. One of these tool manufacturers was the Bonney Tool company and they were located in Allentown, PA. Last month while I was making a delivery of some automobile windshields I literally ran into the old Bonney Tool Manufacturing facility. I had passed this facility on the other side of the building every day but never knew that the plant was still in existence. I have attached some picture of the building with the Bonney name still on the building. While going thru my Miller Tool catalog, I found several pages in which they had listed some of the Bonney tools that were available to all of the Mopar dealerships. I have copied on of the pages from the Miller Tool catalog. So yes we still have some reference points and building that pertain to our old MoPars. You never know what you might find just around the corner or when you take a different route to get to another delivery point. Life is full of surprises and I just wanted to pass this onto everyone. Rich Hartung Desoto1939@aol.com1 point

-

I was lucky enough to have met up with Don a couple of times. He was a great guy with a ton of knowledge. One of my first interactions with him was when I ran into an issue with the flywheel bolts on my B3B. He asked for my address, and in no time I had a envelope with enough hardware for multiple engines. Here's a picture from a car show that some forum members gathered at a few years ago.He was a great guy, and he will be greatly missed!1 point

-

So sad to hear this news about Don. I would like to send my condolences to his wife and family. Don was one of those special person that had a great deal of knowledge about our Mopar family of cars and trucks. He was someone that always had pictures for a person that was working on an issue and was able to explain to the forum members onhow to diagnosis an issue and get you started on the right track to solving the issue. Don came from old way of doing things and was great at passing on his knowledge. As a current society most people only want someone to do the work for them and provide them with the answers to their questions instead of doing some research, but Don was always there to help when ever he could. As club members we still need to support each other in all of endeavors and issues with our cars and trucks and I hope that we can all continue to support each other and continue to pass along the knowledge that we acquire as we continue to be the custodians of our antique cars and trucks. I say custodians, because they really own us and not us owning them. Our goal is to pass the car or truck along to another person that is interested in keeping the hobby alive. Don we will all miss you and you updates and especially your knowledge on cars. May you rest in peace and hope you find another car in heaven. Rich Hartung Desoto1939@aol.com1 point

-

1 point

-

1949 and 1950 Desoto did in fact use drag links. I have on one my 1949 Desoto CV. As far as I could find, Rare Parts is the only game in town. FYI. In my case, I set the two tie rods to the length specified in the service manual. I then centered the steering box. Guess what? the Drag Link is not the correct length! Nothing is bent. I also found specifications from MOPAR sources that contradict themselves as to the length! I am going to, in March when I am cleared to do work, pop off the link and see exactly how much it is off then drive up to Rare Parts (Stockton, CA) and see what they have. They told me they have a wall lined with all the drag links. It sucks that the ends are not replaceable. I did find an off road outfit that manufactures and sells drag links with spherical ends that can be adjusted. I was giving some thought to machining some tapered pins that would be tapered on the one side and have a shaft with threads on the other. Then using this companies drag link. The only thing to deal with then is the slight bed in the drag link. James1 point

-

Thanks Merle--We now have a nice firm brake pedal and don't have to pump it up anymore--Steve1 point

-

1 point

-

" The wiring in these old cars is indeed scary " The wiring in these old cars is not scary. It is in many cases just old. Good grounds and good connections are important when the voltage is low at 6V. When you have 12v or 24v systems, they are more forgiving of such things. I do agree that "load shedding" high current items like the head lights using a relay can be a good idea if one has wiring that is getting brittle with age. However, if you put in a new wiring harness and are using 6 volts, then the system will work for 50 years as expected and is not in any way scary. On the 1947 Desoto, I cut all the wires 18 years ago at the bulkhead and replaced it with new wire for the engine bay and the headlights. I still have the factory wires in the dash and to the rear. However, it is starting to have insulation issues. So when I rebuild it next year it will get all new wiring. On the 1949 Desoto I used an all new stock harness. I added several grounds in the engine bay, two at the rear frame to body. One thing I do on all my cars is the following... I take out the headlight bucket and make sure it is clean and perfect. I then either bolt or use a brass rivet and run a #10 wire from the bucket directly up to the battery for the headlight ground path. I do not rely on the body for that. Doing so makes sure that over time that the resistance in the fender bolts, the fender to frame bolts and the like do not degrade the voltage. I can tell you that I have been driving the '47 for 18 years daily and nothing has burned up yet. But, time is showing itself....1 point

-

I just installed a pair of headlight relays in my '38 Plymouth last week. All new wires and cleaned up grounds. They certainly were improved as they are much brighter. I used a relay for each circuit, (hi & low beam). I also have each circuit wired up with it's own 15A fuse.1 point

-

It saddens me to inform the forum that Don Coatney passed away on the 2nd of December. It is also his wish that no service will be held. Let's all take a minute to honor this man and his dedication to this forum and count our blessings as life is short. Don was a great friend, they are far and few these days.0 points

-

This announcement came to us this AM via Facebook. Long time member and contributor to these pages Don Coatney has passed away. https://www.northernindianafuneralcare.com/notices/Donald-Coatney?fbclid=IwAR3TuqNU5fKgxGaL_gQXkqyCJt-F09m80kr09pwFG5Yc61BjRq6xA6Vadh0 Our condolences go out to Lisa and Don's family. Don's contributions to this forum and these pages were very informative and assisted in keeping a lot of old Plymouths, Dodges, Chrysler's, and DeSotos on the road. Wishing him smooth roads and great scenery on his final trip.0 points

.jpg.67a39991473d5d85cf8819f3dd56d058.jpg)