Leaderboard

Popular Content

Showing content with the highest reputation on 11/20/2018 in all areas

-

2 points

-

2 points

-

I used trex like composite product in mine. An aged silver/grey called something like beachouse cottage or some such. You can get it in thicknesses like 5/8, 3/4, etc. Got it at lowes. Perfect, no stain, machines like wood, wears like iron.2 points

-

I used yellow pine for my bed floor, i was able to find relatively clear 1x6 stock, I used waterproof glue to glue the boards to correct width. I think it would be a bad idea to try to glue the bottom into one large solid wood panel. Solid wood will expand across it's grain no matter what kind of finish is used. If the bottom is separated into individual strips, each board will expand and contract a small amount that can be concealed by the metal strips, if the panel is one large piece it will expand and contract as much as 1/2 inch in width. If you have holes drilled through the panel the board will likely split at one or more of the series of bolts. Plywood will not expand and contract in the same way. Bill2 points

-

1 point

-

1 point

-

1 point

-

Short answer is No, The bodies share no stampings at all. 49 to 52 however, while not identical share many of the stampings including the transmission tunnel.1 point

-

I've been known to scribble on some paper. This selection of subjects are still vehicle related though.1 point

-

What you see is prototype........ Thanks for clearing that up - looks like some "finished product" I've seen!? (the final will be in plywood and not OSB?)1 point

-

1 point

-

anyone remember the bypass filters in the 60s that used a toilet paper element? My father-in-law thought that seemed like a great idea. So he just put a roll in his standard Chevy 216. Really bad idea. Similar to that described above. Mains were toast. Rods weren't as bad, probably since the mains were pressure lubed and plugged, while the rods dippers still worked.1 point

-

If you free it up gently with lube,you may not have to rebuild anything. If it was a good 30k mile engine before getting stuck,it will be a good 30 k mile engine after getting freed up. Use brute force with no lube,and you might break something,bend something,or score cylinders.1 point

-

dpollo, I agree with you. Most vintage bypass filters I see on these engines have the drain/return port at the bottom and are fed from the upper side. However, I also know that mine is clearly marked IN at the bottom port, and OUT at the upper port on the side. It is a filter from the Deluxe Filter Company of LaPort, IN., and it uses the "JC" sock type element. This was marketed as the Heavy Duty filter from Dodge Trucks. Any of the other cartridge type element types I've seen flow from outside-in. Any pleated paper filter element needs to flow this direction as the pleats are more open around the outside, providing more surface area for the filter media. You have reminded me of an issue with a failed bypass filter that I experienced early on in my career. I was working on a Cummins V12 (1710) with bad turbos. The turbos failed from lack of oil pressure. Upon further inspection I found the oil pump suction screen packed full of what looked like shredded cotton. This engine had a pair of Luber Finer bypass filters, along with the spin-on full flow filters. I found that one of the Luber Finer filter elements had split open and spilled its guts through the return port and into the oil pan. What a mess. Now that I think about it, I have to wonder if it had been plumbed backwards. I didn't know any better at the time to investigate that. Now I'll never know...1 point

-

1 point

-

Reg, I did read that somewhere about the starter. I have a later 1953 bell housing I can use. I’m sure I will run into some unexpected challenges but this swap has been done many times so it’s do able. I will keep you up dated on the swap and I am also doing some chassis improvements as well. Thanks to all for the help. Kevin1 point

-

Triple carbs with the RIGHT carbs would be OK. The Ball and Ball carbs have been offered in so many configurations over the years I am sure there is a set of triples that would work splendid on a stock motor. The problem is - I have no idea what carbs to tell you to look for other than ones with small venturis. If they can tell you what carbs would work and you have room to fit everything - then I see no issue. Without that magical piece of knowledge or the desire to figure it out.... then I wouldn't go that direction.1 point

-

1 point

-

Hi Andy - sorry to take so long to get back to you, but I finally got the water pump rebuilt and back on the car. While it was off, I removed the engine drain cock and poked around inside the block with a piece of wire. After poking around a bit, the coolant poured out, so I think we got that problem sorted. I also checked the freeze plugs, as you also suggested, and they all look OK, so I’m just leaving them alone for now. As for the rebuilt water pump, it has a two blade impeller like the original, but they did install a sealed bearing, so there’s no need for grease, although they did put the original grease nipples back on (probably for originality purposes). I then took the car to my mechanic and had him flush the system, completely replace the antifreeze that I had put in the car (as I wasn’t happy with the mixture/protection) and change the oil to get ready for winter storage. Anyway, back to the water pump, the car seems to run a bit cooler, and so far, I’m happy with the rebuild. It was a fun learning experience that will hopefully give me the confidence to attempt more repairs/projects in the future. Thanks again for all your help. - Rosco1 point

-

Yeah for the price I couldn't say no. I also have a bunch of parts already and have some experience with these cars so shouldn't break the bank. I took to cleaning the car some more. The drivers side is starting to look better. I'm totally into the patina look for this one, so other than running and driving and dealing with floor rust, I'm going to enjoy it as is once buffed up. I'll get some new tires and keep it as stock as possible. I prefer original for my cars as opposed to modified.1 point

-

1 point

-

Cold Blue's connections are backwards. I have seen the stuffing of the element work its way back to the pan when a filter is hooked up this way. This material is then picked up and circulated to the bearings where it will block the annulus on the end mains , resulting in bearing failure. Conn47, your original diagram is correct. Also, the filter is the by pass type where it filters about 15 to 20% of the oil at speeds above 30 mph when the oil bypass is open. Not as good as found on Chrysler sixes and all modern engines but better than nothing.1 point

-

1 point

-

If change is hard to deal with why don’t everyone just give it to a good nonprofit organization like your local Lions Club or The Salvation Army. No more stress and you did something good.1 point

-

I took my son often to many junkyards off the beaten path when he was growing up. He told me recently that was the coolest thing he remembers as a kid and was so fortunate to have been able to see all the old stuff. He's a gearhead now himself, loves vintage autos and is a pretty darn good mechanic. Which is unusual for this generation. We had fun, it was always like a treasure hunt.1 point

-

I think they were built well. I don't think Ma Mopar thought these cars would be running 70 years later? Fatigue starts the first day after construction, it's only a matter of time after that point.1 point

-

Had a old ford 390, one morning it was running rough, leaned over the fender and whacked the throttle a few times. Blade let loose and buried itself 6" deep in the inner fender that I was leaning over .... needed to change my pants that morning before work.1 point

-

1 point

-

I have old pressure treated lumber in mine. The previous owner did it and as the metal strips were missing he just butted it up against each other. Not the answer for a show truck, but for a driver, or in our case it has been used on and off on our evergreen nursery to haul equipment in the field between long "rests" stored awaiting being put back in street legal condition it works well. Looks okay too for a working truck that has been outside for at least the 15 years we have owned it and before that too. Disregard the paint on the bed shaped like parking light surrounds.1 point

-

If you are gonna glue them together why not use a sheet of Marine plywood.They make some with really good looking veneers.1 point

-

"The battle, sir, is not to the strong alone; it is to the vigilant, the active, the brave." -Patrick Henry Peace. USAF 1970-19741 point

-

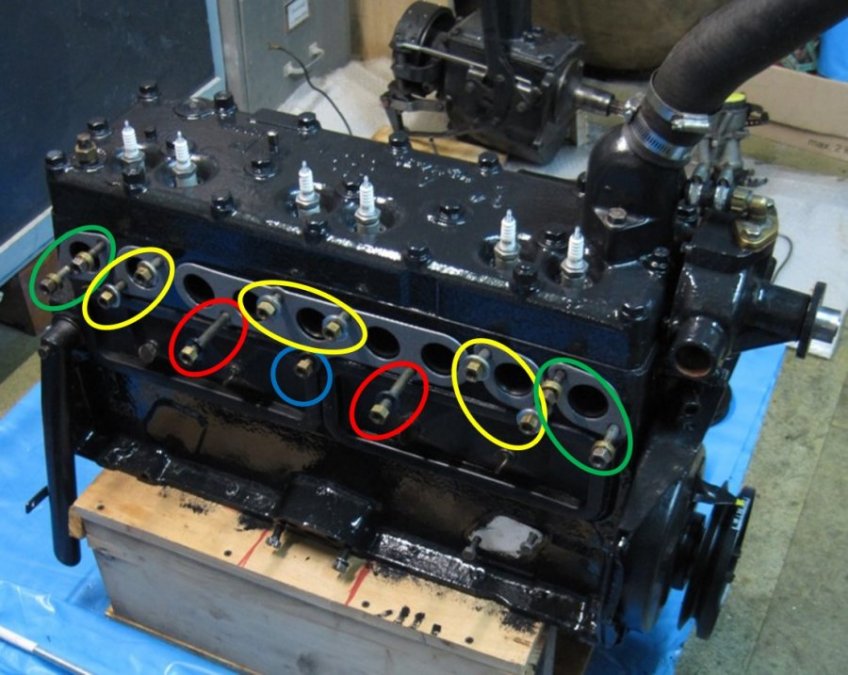

Wondered that too, when I got my new nuts and washer sometime ago. Here my thoughts: Requirement is, that the bolting doesn`t lose its preload to ensure the manifolds doesn`t leak. Parts do expand when getting hot and contract, when getting cold. So the bolting has to compensate that movement. Bolts / studs are working like a spring when properly tightened. Longer ones do have a better preload=self-lock than short ones. Assumption: no additional locking precausion needed on the long bolts, so standard washers and nuts are used (red circles). On the other hand a reason to use conical nuts on short bolts (green circle) might be, that not enough self-lock is guaranteed. The slots on those nuts are working like a locking device. The conical washer are needed as a counter part of course. Remains the question why there are short bolts without conical (lock) nuts: Those with the yellow circle have to hold two manifold flanges. Therefor a washer with a larger diameter is needed. Assuming these are no special made items but standard parts, there doesn`t exist conical washers with a larger diameter. So regular washers and nuts are used. On that with the blue circle there is just not enough space in height to put the conical nut and washer between the manifold flange and wall. Regarding the different material. Brass parts doesn`t seizure like steel. The conical nuts need to be of steel due to their job working as a spring, too. Just my assumptions ...1 point