-

Posts

15 -

Joined

-

Last visited

Reputation

2 NeutralProfile Information

-

Gender

Male

-

Location

Glen Ellyn, IL

-

Interests

Hobby Farming, New Product development & design, Automotive Restoration Projects, Welding, Programming.

-

My Project Cars

1948 Dodge B-1-B-108 1/2 Ton Pickup.<br />

1948 Ford 8N Tractor.<br />

1974 Corvette Roadster

Contact Methods

-

Yahoo

dandyj47@yahoo.com

-

Biography

BSEE with some Mechanical Eng. 38 Yrs Design Engineering.

-

Occupation

Electronic Engineer

Converted

-

Location

illinois

-

Interests

Singlehandedly acheiving world piece, finding the cure for the common cold

Recent Profile Visitors

1,177 profile views

-

I very much want to thank all of the Forum members for their interest and suggestions. A long time member is very graciously taking everything that I needed to find a new home for, so nothing will go to the recycler. I still have my B-1-B-108 in a barn in Wisconsin, but have had my moving dilemma resolved. A question for the Forum experts; Is this update sufficient, or should I attempt to remove my initial post or the whole topic instead ? Thanks.

-

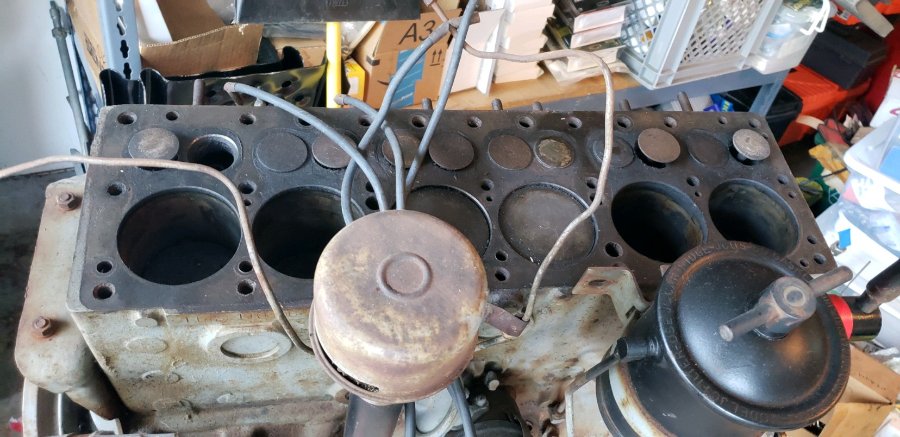

I'm moving and can't take with me a 218 CID engine flathead 6, with clutch, bellhousing, and 4 Speed Transmission with emergency brake. Engine is on a new engine stand which also goes for free. The equipment is in the outer western suburbs of Chicago in DuPage County where we reside until moving on 9/14/21. The only catch is that it needs to be picked up ON OR BEFORE 9/12/21. I have an engine hoist to assist in loading if needed. I would desperately want to find a good home for the powertrain otherwise I'm forced to get it to a metal recycler. Please text or call (630) 334-1923 if you would be interested in taking equipment. Thank you, James

-

I'm moving and can't take with me a 218 CID engine flathead 6, with clutch, bellhousing, and 4 Speed Transmission with emergency brake. Engine is on a new engine stand which also goes for free. The equipment is in the outer western suburbs of Chicago in DuPage County where we reside until moving on 9/14/21. The only catch is that it needs to be picked up ON OR BEFORE 9/12/21. I have an engine hoist to assist in loading if needed. I would desperately want to find a good home for the powertrain otherwise I'm forced to get it to a metal recycler. Please text or call if you would be interested in taking equipment. Thank you.

-

What is a fair price to ask for a complete 230 CID flat six motor with clutch / bell housing, 4 speed transmission , and integral parking brake ? I have to list and sell it and don't know what it's worth. The # on the block is TI42*II0405*. I'd be most grateful for any experienced input before I list it.

-

Copper Compression Gasket ? ? ?

James-48-B1B-108 replied to James-48-B1B-108's topic in P15-D24 Forum

Yes it was copper, I'll give it a try, pretty interesting, thanks. -

Copper Compression Gasket ? ? ?

James-48-B1B-108 replied to James-48-B1B-108's topic in P15-D24 Forum

As a final follow-up, I finally got back to the truck and took the calipers to the gasket I found in the drain pan and the drain plug itself, and measured 22mm ID X 30mm OD X 1.5mm Thickness. Found: 20Pcs 22x30x1.5mm Copper Crush Washer Flat Ring Seal Gasket Fitting M22 on Amazon.com for $7.99 with free shipping. Thanks again for your help. -

Copper Compression Gasket ? ? ?

James-48-B1B-108 replied to James-48-B1B-108's topic in P15-D24 Forum

Thank you all for your input, I've been traveling and couldn't check my topic string until today. The truck is up in the barn which is 250 miles north of where I live, and now that I know it needs a washer, I will have to locate a new one and bring it up with my next visit. That is extremely helpful for sure. -

Changed the oil on my '48 B1B and the drain plug slipped from my fingers and fell in the oil change pan. After the oil was fully drained, I reached into the collection pan and fished out the drain plug, threaded it back in the oil pan to a reasonable torque. I filled the crank case with fresh oil and then proceeded to empty the collection pan into an old jug. When empty, on the bottom of the pan I found a large copper compression washer of a size that looked about right to be able to fit around the drain plug. Is there supposed to be a washer around the drain plug ? ? I'm not eager to drain the new oil to check this out and not surprisingly, I can't find any diagrams that show a detail of the pan and plug. There doesn't seem to be any seepage of fresh oil around the drain plug. I would very much appreciate a dose of your knowledge on this and apologize for making a short story long.

-

Regarding possible (perhaps probable) causes of the engine being locked up, for what it might be worth, I have an extra engine and transmission which I could only turn back and forth a few degrees by wrenching the manual crank nut on the damper pully. On removing the head and oil pan I could see that the pistons moved up and down a very small amount but the exhaust valves were frozen in their guides and were the total cause of the lockup. Replacing those bad valves and their guides was all that was needed for the engine to turn freely. The bad part is that removing frozen valves in a flathead motor is no easy task.

-

'48 B1B Glove Box spring connection points.

James-48-B1B-108 replied to James-48-B1B-108's topic in P15-D24 Forum

What phenomenal support, thank you all, very much ! Now I'm itching to get to the barn and finish installing it. I hope that after a learning period, I can provide such help to others in the community.- 14 replies

-

- glove

- compartment

-

(and 3 more)

Tagged with:

-

I have finally acquired a spring for the Glove Box in my 1948 Dodge B1B and pocket like installation point on the bottom of the door itself is the obvious connection point, but where does the other end of the spring attach. Would really appreciate some instruction on this.

- 14 replies

-

- glove

- compartment

-

(and 3 more)

Tagged with:

-

carburetor Factory Appropriate Carburetor

James-48-B1B-108 replied to James-48-B1B-108's topic in Mopar Flathead Truck Forum

Thanks for the information, so it would be either an E7B1, E7C1 or E7F1 as delivered for the 1948 B1B. I'll start looking for one of those.- 5 replies

-

- carter

- ball and ball

-

(and 1 more)

Tagged with:

-

carburetor Factory Appropriate Carburetor

James-48-B1B-108 posted a topic in Mopar Flathead Truck Forum

Only been at this for a year, and I'm hoping to draw on your collective knowledge. The 1948 B1B-108 1/2 Ton Pickup I have has a Carter Ball & Ball Model D6H2 which I am told is not the original model for that application, what was the factory installed model for that year and model pickup built mid-year in Detroit? Thanks very much for your help.- 5 replies

-

- carter

- ball and ball

-

(and 1 more)

Tagged with:

-

Great post Jocko_51_B3B ! I have a 1948 B-1-B with a spare engine which I have started to rebuild and has several exhaust valves frozen to the guides. The one that was frozen partly open I was able to use a large channel lock pliers to rotate back and forth to free up, BUT of course, those in the closed position don't permit grabbing with a pliers. So if you don't mind, I have a few questions relating to your post regarding welding nuts to the top of the valve head to provide a place to grab and twist free. 1. would you mind providing as many details as possible about your weldments: (all around the hex, inside the thread area, etc.)? 2. how large of a size nut did you use? 3. How critical was centering of the nut to minimize shear forces? 4. What welding system did you use (ie. Stick, MIG, Oxyfuel, etc.)? 5. How readily did the valve face bead accept penetration? 6. Did you end up replacing the offending valve guides along with those valves? THANK YOU very much for any and all information you would share, I'm determined to save my engine block. James