-

Posts

358 -

Joined

-

Last visited

-

Days Won

6

johnsartain last won the day on July 24 2018

johnsartain had the most liked content!

Reputation

105 ExcellentAbout johnsartain

- Birthday 07/11/1960

Profile Information

-

Gender

Male

-

Location

Sierra Vista AZ

-

Interests

Into Motorcycles and off road, woodworking

-

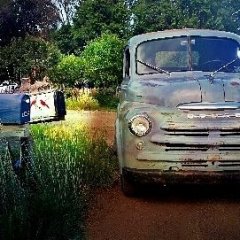

My Project Cars

2000 Dodge Durango, 1950 Dodge Model B-2-B, 1950 Dodge Model B-2-C, 1965 Rambler Classic 770, 1964 Rambler American 440 H

Contact Methods

-

Biography

57 years old father of 4

-

Occupation

Software Engineer

Converted

-

Location

Sierra Vista, AZ

-

Interests

Motorcycles, Off Road, Old Cars, and Old Trucks

Recent Profile Visitors

3,182 profile views

-

Has anyone ever adapted a Heating and Air conditioning blower box to fit the1948-1951 Dodge Pilothouse cab? I am hoping that there is an option such as one from a Dodge Dakota, Ford Ranger Pickup, Ford Explorer, or even maybe a Chevy S10, or Blazer. Although I prefer to try to use the Dakota so my harness from the Ram 1500 will work, I may have to cross breed and gene splice this thing. If all else fails there is Vintage Air. The one I scavenged from a 1997 Ram 1500 is just too big.

-

Properly tuning your engine and setting the timing also affects the amount of manifold vacuum that is generated. You can observe this by connecting a vacuum gauge and adjusting the timing. You will see the vacuum increase as you adjust the timing. Many old timers use a vacuum gauge to set their timing rather than a timing light. One guy recommended to me to set the timing to a point where the vacuum is at it maximum. I did so and found that although the timing was a bit advanced when observed with a timing light, the engine ran better. The 218 and 230 flattie's have a lower compression than most modern engines so pinging wasn't a problem either.

-

I recently started building a back up 6 cylinder flathead engine for my truck. All I got was the block and crank. I had a set of connecting rods and pistons from a prior engine build but may likely get a new set of pistons as they appear to be standard bore. I was trying to remember about how the offset worked on the connecting rods and I will share what I found out about the offset of the rods. Even though I have found some information on this site it seems to be pretty scattered about and I found myself wanting for clarification. This is my take from what I have seen with my engine and connecting rods. Factory rods for the 23 inch 218 and 230 engines are numbered 1-6 at the rod end caps denoting which cylinder they go to. The numbers are not always clearly stamped and in some cases nonexistent. I have read of several instances where engines may have a number 3 rod on a number 1 journal. I assume this is ok if a rod needed to be replaced as the offset would be correct. On rods 1-2 the thinner sides of the wrist pin boss goes together. Same on 3-4 and 5-6. The Connecting rod bolts are offset as well. Facing the camshaft side of the engine with the #1 connecting rod to the right, the #1 rod bolts are offset to the right and the #2 are offset to the left, same with 3-4, and 5-6. When rods are not clearly stamped, scuffing with a scotchbrite pad on the sides of the rod and cap will possibly reveal a number on the rod and/or the cap. This is only based on my experience with my engines. Other may have had different experiences and your contributions to this thread are welcome even of your experiences contradict mine.

-

-

I'm not sure how many springs you have broken, there were just a couple on mine. I used 3/16 brake line, bent to the curve of the spring and enough length to extend an inch and a half or so past the break. After slipping them on, I crimped them to hold them in place. It worked fine for me.

-

Just curious, I have a 94 Pace Arrow motor home that has a 19.5 inch rim. It uses the same rime all the way around, drive axle, tag axle, and front axles. They are a 10 hole rim but for the front end only 5 lugs are used. I have to wonder of this is workable for your application? The GM P30 chassis.

-

US Radiator carries a near original 3 and 4 core radiator which would be ample to do the job. The Link I am sending is is for a radiator that would fit the truck in its original radiator mounts without modification. Of course if modification is not an issue there are several bottom and top tank radiators you might use that can beat he price. http://www.usradiator.com/dodge-truck-1948-54-radiator.html

-

I found it interesting reading about the tube, mostly concerning the manifold bolts. Using a flat steel bar makes sense as well. I was skittish about pounding a bar in beside the tube. The reason I am concerned about the head bolts is that mine are not new old stock bolts. They are Pioneer PG-362-25 bolts of the same size thread and are about 1/4" longer than stock bolts. Knowing that the water distribution tube is accessible behind the manifold bolts gives another option to break it loose from the side of the water jackets as well.

-

After having difficulty replacing my water tube and failing to extract the bugger, I was wondering what the odds are that the water tube in a flathead 218 aligns with the middle row of head bolts? (I did not disassemble this engine completely and tried to do it with the head still on.) Might that make it more difficult to pull and replace the water tube with the head bolted to the engine? This could be an issue particularly if the bolts are a shade too long. Thoughts anyone?

-

I am posting these links again for everyone's information. It seems that it keeps getting asked and every time I look it cant be found so here goes. If you need a good source for remanufactured starters these are the links for two sources. https://www.filterspro.com/WILSON-91-06-1821_p_1843669.html and http://www.oreillyauto.com/site/c/detail/WIL0/91061821.oap?ck=Search_mch6106_-1_3090&keyword=mch6106 Filters Pro has no core charge

-

The crossmember does get in the way. It's worth a try and the radiator removal does give a little more space.

-

60 psi doesn't sound like a big issue. The gauge goes up to 80, if I remember right. As long as you don't peg your gauge, there are not any other problems that will likely occur at 60 psi or less.

-

I read a study recently that claimed that humans eat more bananas than monkeys. For the life of me, I cant remember ever eating a monkey.

-

Have you replaced your Fuel cap by any chance? New caps are non vented. This will cause a vacuum to be drawn on the tank and reducing fuel flow.It can reduce it to the point that the carburetor starves of fuel and the engine dies. If you have bought the new non-vented cap, it can be converted to vented by removing the center piece from the cap.

-

What amazes me is that after 74 years, all of a sudden over the past 2 Christmas's someone has decided that they are so smart that they figured out that the song is about data rape. Everyone before them was too stupid to realize this. Hundreds of thousands, might I say millions of people have all been wrong for YEARS, thus wrongfully enjoying the song. But suddenly the offended few are the only ones woke enough to realize this and now it must be banned. Here's a hint. When everyone else is wrong, and your the only one who's right, re-evaluate your perspective.