-

Posts

16 -

Joined

-

Last visited

Reputation

1 NeutralProfile Information

-

Gender

Male

-

Location

New Jersey

-

My Project Cars

1947 Dodge D24, 1959 Ford Thunderbird

Converted

-

Location

New Jersey

-

Interests

Cars

Contact Methods

-

Occupation

Ditigal Strategy

Recent Profile Visitors

421 profile views

-

If I recall, I believe they are flush with the deck, but I don't recall 100%

-

Thanks, didn't want to force it if it wasn't meant to come out.

-

I have searched this site and can't find what I'm looking for. I am replacing the Master Cylinder and it looks like the new MC doesn't come with the Shaft Pedal Pin. Should the Original Pin slide out or push out? Thanks in Advance!

-

Thanks, I am going to take one more close look at them before I decide what to do. Thinking inspecting them for any real damage or wear might be a good idea to be safe before I go crazy.

-

Thanks! You are correct, I actually took a minute and looked that gasket in comparison to the block and it does only go on one way. I did pick up the permatex coating as well and thanks for the info on torqueing increments, that'll help out.

-

I hadn't planned on needing to this deep into a project, but all of this makes absolute sense. I assume I will need to remove the valves in order to lap properly. Do I need to compress the springs in order to remove the valve? is so, what would be the right tool to use? This is my time playing with a Dodge and a flathead so I don't want to assume it's like my ford FE. I am also reading through the shop manual, but real world comments sometimes are better. Thanks Again!

-

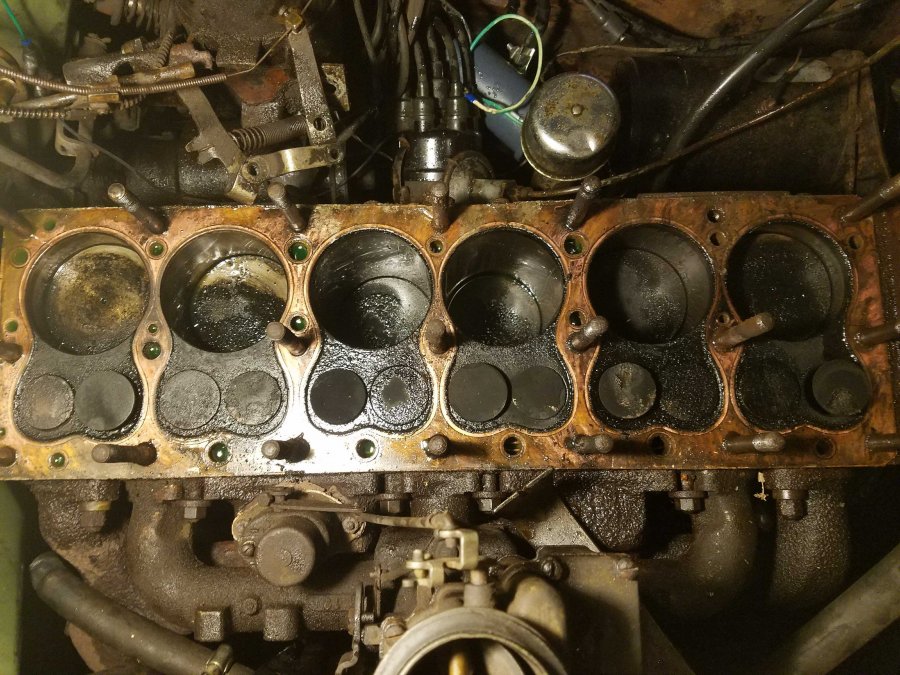

Couldn't get a clean shot of the valve without getting in and removing them. Having said that, the valves aren't in bad shape but do have some wear on them. My question to the team is... Is it worth changing the valves? Are there any advantages to changing them or disadvantages if I don't? I have everything cleaned up and ready to reinstall the head, but wanted advice on the valves before I proceed. Thanks for the great input for this project!

-

Found these on another old thread...curious if they worked... https://www.summitracing.com/parts/pio-pg-362-25/reviews/?sortReviews=Newest https://www.amazon.com/ARP-Head-Bolts-Chevy-396/dp/B001T68KLK?tag=viglink121987-20 I am thinking of the first set. There are reviews that people have used them for the dodge. and they are cheap.

-

My old gasket was copper on both and I noticed my new gasket has a copper side and blue side. It does not state which side up on the gasket, does anyone know if it matters? Also should I use some type of sealing compound on the head gasket to ensure a proper seat? I always had mixed feelings on this.

-

Thanks I will. The valves seem to be moving freely now.

-

Odd, I replied to this but it didn't look like it was posted. I did pick up a can of flat black to give the head and water neck a shot to clean it up a bit. I thought about the bolts, but shockingly the bolt screws came off very easily and appear to be in great shape. I am guessing the gasket was replaced before and maybe they didn't tighten to spec, maybe that's the reason for compression issues. If I keep her longer term, I will plan a complete rebuild and engine clean up. under the hook is kinda dirty and wiring appears to be original.

-

Thanks for the great info, I will be looking into this this evening. I lubed up the valve she is moving again nice and smooth. One other question...What are the recommendation for cleaning the valve and pistons while still in the engine? I have only ever cleaned and restored during rebuilds. As you can see in the above pics I have some nice crud on the valve heads.

-

I have done some research and all signs are leading towards head gasket replacement, but wanted to get some advice while I am thinking about it. The back story...My 47 D24 sat for about 2 years and every once and a while I would try to start her with no luck. I recently replaced the battery and ground wires and was able to get her started, but the intense smoke filled the garage so bad, that I had to stop the car. I check the compression on all cylinders and here are my results: 1 - 0 psi 2 - 90 psi 3 - 75 psi 4 - 75 psi 5 - 65 psi 6 - 70 psi I pulled the head and the 1 cylinder has a stuck valve, but all others seems to be opening and closing OK. 2 questions...1) how do I unstick the Valve? 2) while the head is off, is there anything else I should look at as far as maintenance? Thanks!

-

I used the instructions that came with the unit, but being new to this style car, was looking for experienced advice. The particular model that is designed for the 47 show one wire to the Neg. (-) and the other wire to the ignition switch, just not sure where to wire that one since this car has the key and push button start. Thanks again for any help.

-

not at the time of the install, that was one reason for the upgrade. not saying this is the issue, but still trying to troubleshoot.