-

Posts

262 -

Joined

-

Last visited

-

Days Won

1

3046moparcoupe last won the day on October 24 2017

3046moparcoupe had the most liked content!

Reputation

56 ExcellentProfile Information

-

Gender

Male

-

Location

Hurst

-

Interests

Music/Guitar and Old Cars / Streetrods

-

My Project Cars

1930 Plymouth Model-U 3 Window Coupe, and 1946 P15 Plymouth Special Deluxe 2 Door Coupe

Contact Methods

-

Biography

60 yr old OCD / Old Car Disease

-

Occupation

retiree

Converted

-

Location

Hurst Tx

-

Interests

Vintage Mopar, guitars

Recent Profile Visitors

-

205-70-R15 tires on a P15 ? anybody ? pics ?

3046moparcoupe replied to 3046moparcoupe's topic in P15-D24 Forum

beautiful Greg.. -

205-70-R15 tires on a P15 ? anybody ? pics ?

3046moparcoupe replied to 3046moparcoupe's topic in P15-D24 Forum

Thank you all for the reply's back. From my research, I would agree with what was also shared about the original wheel size being 16" for the P-15,...then the 15 " wheel came along later. Greg, a google search tells me that the 215-75-15 's (tires I have) are 27.7" diameter, (close to the 28" measurement you mentioned), and the 205-70-15's I'm considering are 26.3 " diameter...(it does make ya think when ya see the difference in rotations per mile but I do believe I will be driving it 90+% just around town 30-40 mph.. Thank you Adam for the pic and text,.. when I searched 205-65-r15 dimensions, it came up with a 25.5" tire diameter,...compared to my 215-75-15's, that a total overall diameter difference of almost 2 1/4" smaller. Your pics just a little angled, (by the way thank you again for the pic), but from what I can see, the wheel well doesn't look overexposed to me at all, nothing low rider looking about it to my eye...I might even consider going with the 205-65-r15's like you have,.. which would lower my stance ( 2 1/4 " divided by 2 = 1 1/8"). Beautiful business coupe Andy, thank you for the pics,..why did you sell it ? Steve -

When we got our 1946 Plymouth P15 Club Coupe project, it came with it's mopar steel 15 x 4.5 " wheels and a set of P215-75-R15 tires. Typically the tires looked like new but were over 10 years old, so I had the wheels sandblasted, then powder coated, and I replaced the P215-75-R15 tires. I just purchased a set of US wheel 15 x 5 " chrome smoothies and was considering getting a set of P205-70-R15 tires mounted up for the car on the new chrome rims. Reason being: I will want to lower the stance on this car some and just this tire change will get me almost a 3/4" drop. However, I'm not at all interested in the car looking like a low rider (please no offense to you low rider guys or gals intended , anyway - thought I might just ask here on the forum,...before proceeding forward,.. ANYONE OUT THERE RUNNING 205-70-R15 TIRES ON THEIR P15 ? and if so, if ya can attach a picture that would be great... thanks Steve

-

I sure hope I'm not violating policy here ( I don't believe I am), as I'm not selling anything,....but I did want to try and take this opportunity to share and hopefully give back to my forum members here who have done so much to help us with our project, an opportunity to stretch their hard earned dollars just a little further. That said, I just recently sold a Cargo trailer I haven't been using much the last few years, and the proceeds have allowed me to obtain a few of the more expensive items I have had on my wish list for the car for the past 5 years.. In the process of looking I stumbled across the following and wanted to share for those out there who might not be aware. Steele rubber's one piece windshield gasket (with the slot for the stainless molding trim), pp#40-0274-50 and Steele Rubber's one piece (requires no splicing) back window gasket, pp# 40-0454-81 are both available through Bob's Classic Auto Glass located in Oregon. The cost savings by purchasing through Bob's is $90.50 for both items combined. I spoke with Steele Rubber about this, and they confirmed that these gaskets are legitimate, new, Steel Rubber products and that Bob's purchases from them in bulk quantities. Steve

- 1 reply

-

- 2

-

-

Installing a Spin-on Bypass Oil Filter (photos)

3046moparcoupe replied to Sam Buchanan's topic in P15-D24 Forum

Thank's Sam I appreciate your kind and courteous reply back. Without a doubt, my biggest handicap with all this (restoration work) has been made evident over the past few years (especially to myself) in regards to how badly I can over analyze things, and in the process very often just " not see the forest for the trees". Trying to do better with it. Man old habits are hard to break. I do want you to please know, I would never try to be a smarty with anything I write or say here on the forum, (it honestly was a sincere however maybe misguided concern on my part) in regards to the oil spillage. I think your simple idea of a plastic bag, sturdy enough and stout enough to handle some hot oil, is about as good a suggestion as anyone could make, and 1st grade simple to boot. ( Again the "forest for the trees thing raises it's ugly head" ). I thought I was a pretty good wrench, when I started this project almost 5 years ago, however soon I realized how much of a "good parts replacer I had been over the years". One things for sure, my project would be no where near what or where it is today, without the help I've received here on this forum. I really appreciate the patience extended my way from everyone. Steve -

Installing a Spin-on Bypass Oil Filter (photos)

3046moparcoupe replied to Sam Buchanan's topic in P15-D24 Forum

Looks great Sam, nice job on the bracket. I was strongly thinking about doing exactly the same thing, (replacing my cannister oil filter housing with a Wix spin on, same exact part numbers you have used here),...as I need to (at a minimum) replumb my old cannister filter with hard metal lines to replace the hoses that the previous owners had used to plumb the in/out flow to and from the cannister to the block, and I had thought that doing the change to a modern spin on filter would be a good, in-expensive, upgrade. Then I got a little spooked when I read some reviews on folks claiming to have received filter brackets from Wix that were poorly machined when manufactured. It wasn't here on the forum, but out on the internet when searching for reviews. Some were stating that they received filter brkts that were not built square in relation to where the filter threads on, and the gasket sealing area, so the filter would not seal. Others however were worse, and I saw more of this same second bad review repeated several times, and that being. The threads on the large threaded tube where the filter spins on were uneven, jagged, sharp, etc,...enough so that when the filter was attached to the bracket they were claiming it was damaging the threads on the oll filter itself and actually pulling metal filings from the female filter threads that they felt would end up inside the engine. After reading that crap, I thought well - there's no way for me to know if these reviews are legit, and/or if actually true, were those rare instances. Hummmm, I suppose one could get past this concern once the bracket and filter were in hand, by screwing the thing together and then taking it apart to check for fitment and/or any signs of metal glitter. I've screwed enough filters on in my life, I suppose I could possible tell by just the feel of it.. At this point I thought about how every time I do an oil change on our modern cars, and I loosen the filter,..and you get that immediate spillage of oil when the gasket seal is broken that you put your drain pan underneath to catch, wait on to stop, then wipe clean with your rag ang go ahead and remove the filter. With the starter directly underneath I began to wonder if the spin on by-pass filter would be nearly as messy. Without any anti drain back valves in the top of the by pass filter it might not be nearly as prone to spill over like a conventional filter does, to the point where just a rag or two underneath the filter to cover the starter would be plenty enough to keep oil off the starter, so maybe not an issue at all. ..I don't know ?? All this had me to the point where I thought I might just be better off to stay with the old design, where you remove the filter lid and lift the old cartridge out. Your thoughts or ( anyone else out there who's had experience with oil spillage associated with removing a modern spin on by-pass filer installed on the side of the engine block above the starter), would be appreciated. thanks Steve. -

46 P15 Canister oil filter hose routing question

3046moparcoupe replied to 3046moparcoupe's topic in P15-D24 Forum

Thank you Merle, I believe we might have this cat skinned :), and I want ya to know (here on my end) that your effort and sincerity to truly help is obvious, valued, and much appreciated. Thanks for helping me work through this. When I drain the cannister and open it up to do the re-plumbing, I'll give everything a really close look for any kind of in/out markings, and if I don't find anything to the contrary, I'm gonna re-plumb it with the hard lines back the way it is currently, flowing from inside - out. Steve -

46 P15 Canister oil filter hose routing question

3046moparcoupe replied to 3046moparcoupe's topic in P15-D24 Forum

Merle, I was looking again at the diagram that DB4ya posted, and that you were good enough to commented on, about seeing different flow patterns. Am I wrong here, or is it showing two different style housings with the input and output ports opposite to each other (as far as the plumbing lines go), but when you look at the actual oil flow arrows inside the cartridges themselves, unless I'm mistaken they both appear to me to be showing the oil flowing from the inner tube area of the filter cartridge itself, outward. ?? Am I not seeing this correct and missing something here ? thxs again, Steve -

46 P15 Canister oil filter hose routing question

3046moparcoupe replied to 3046moparcoupe's topic in P15-D24 Forum

Merle, you are absolutely correct, MY BAD,...I should have looked back at my picture before just speaking off the top of my head. You'd think as much as I've looked at this I could remember. I suppose it's all starting to run together a bit. But YES, you are correct. Therefore in agreement with your understanding of how cellulose pleated filters work, these lines should be reversed. Sorry about that, and thanks for going the extra mile and pointing out my mis-spoken error . I appreciate your thoroughness and extra effort. S. -

46 P15 Canister oil filter hose routing question

3046moparcoupe replied to 3046moparcoupe's topic in P15-D24 Forum

Thank you Merle, (DB4YA and Pete),..well Merle (last night the more I thought about your previous statement it dawned on my that you had to be talking about the filter cartridge itself when you stated that flow direction would depend on the filter design). So I called WIX Customer Support this morning to ask them and they dodged the question every way they could, just simple would not answer it. I got reply's back like this: (QUESTION) Which was is oil flow in and oil flow out for this filter ? (ANSWER) when you put the filter in, have the bail wire handle pointing up. No sir, I'm sorry let me explain my question again, I should have been more clear (QUESTION): Which way should the oil flow through the filter ? Should it come into the filter from you pressurized oil output port on the engine block into the filter cartridge through the bottom center hole and exit the filter cartridge through the side walls to return back to the engine block ? (ANSWER) There is no pressure in a bypass filter setup. (QUESTION): Does it matter which way the oil flows through the filter ? Does the filer cartridge element care which way the oil moves through the filter for it to do it's job ? (ANSWER): It's an enhanced cellulose filter with some additional material for support in it, with no anti drain or bypass valve in it. (QUESTION): Does this pleated style filter cartridge care which way the oil flows through it to do it's job ? Like my home AC pleated fiber filter does, where you have an arrow on the side of the filter showing which was is in and which way is out for proper air flow filtering ? (ANSWER) My documentation doesn't show anything. Well, I appreciate your time with this, thank you and have a nice day....:) Merle , he did know that a by-pass filter doesn't filter all the oil, that it only filters a portion of the oil as the engines running,...and he didn't sound like a young kid,....but it was like trying to count hen's teeth to get an answer from him,...a lot of long moments of silence. Well, I appreciate your help with the detailed reply back, showing the WIX filter itself, confirming the numbers I gave you, and stating that per your understanding, most pleated cellulose filters filter from the outside inwards, which is the way this cannister is currently hooked up. A little over 4 years ago, when I got the car, one of the first things I did was remove the cannister, clean it out, and while it was off the car I painted it to get rid of any cancer,....when I put it back together, I did a non detergent oil change and put the new WIX filter in it. I don't remember any markings on the filter itself (in /out), and I don't see any markings on the pictures of the filter shown on the Wix web site, but since I'm gonna re-plumb this cannister anyway with hard lines, I'll take the lid off, remove the filter and check it again to see if there's any markings showing in and/or out. if I don't see anything, I suppose the best I could do would be to hook it back up the way it is now, which does agree with your comment about "most pleated style cellulose filters filtering from the outside - in.... Steve -

46 P15 Canister oil filter hose routing question

3046moparcoupe replied to 3046moparcoupe's topic in P15-D24 Forum

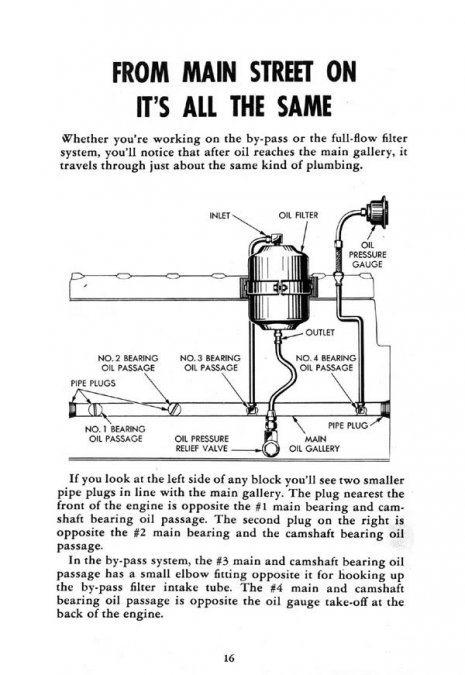

Thank you Pete, 9 foot box, and Merle. I sure appreciate the input. Don't know that I've heard from Pete or 9Ft before, but Merle has helped me out many times, as I think I'm probably the "KING" of the question asker's here on the forum That said, the senior forum members here really deserve a big THANK YOU shout out as I don't think I've ever asked a question here on the forum that hasn't been addressed, and typical very quickly. Best forum (or I should say forum members anywhere). Pete, that was my last thought before pulling the garage door down last night, after starring at this for a bit,....if I clocked the entire cannister 90 degrees clockwise, it would pull the hose away from the rear f the starter and the upper hose looked like it would have enough slack in it to allow for the turn...at that point however I decided to pull the garage door down and reach out to the forum for some experience. As usual it payed off, as both Merle and Rallyace were kind enough to confirm that these lines should be metal, which makes perfect sense. I can make them up just like a hard brake line and they will be out of the way and way more reliable, than hose. As far as which line goes where..one thing I've learned during the 5 years working on this project is to not assume anything is correct,...(I'll be honest here, at first I thought it actually might not matter, as long as the oil did pass through the filter), however I didn't want to leave it at that, so before posting this reply, in effort of trying to confirm which hose goes where , I tried looking at pictures I could find on the internet, here on the forum and just on the internet itself. Basically in the pictures I found that did show the in and out routing, as Merle stated "best as i could tell in the photos I found it done both ways", so I still didn't have a confirmation on this...then I found a diagram that Don Coatney had posted in the past, which really seemed to help. I've attached some of the pics "which seem to show it done both ways" and also Don's diagram "which in my mind is the answer I needed. Reason I say that is (when I compare some of the pictures I found, to what I see on my engine), it seems like all the ports on these blocks were not made exactly the same way. The two ports on my engine are one above the other, with the top port threading in horizontally into the block (in my mind - this would have to be the #3 bearing oil passage galley port shown in Don's diagram ) as this port is in direct line on the engine block with the other 4 bearing ports shown on the diagram. The diagram shows this port as "IN" to the filter, and it would make sense that this port is connected to the same oil pressure being used to lube the bearing. The lower port on my engine is threaded vertically into the casting of the block, and as shown in the diagram that is the filter outlet side to engine block return port coming from the bottom center of the oil filter. All that being said and shown, It would appear to me that 9 ft box might just be correct in his statement that the lines on this cannister filter are hooked up backwards, but again - I know Merle has mega experience and I need to better understand what he meant when he said "filter design". Merle am I anywhere close to understanding this and getting this correct ? Or in your previous reply back, if you were meaning that the difference is in the construction of the actual filter element itself, I am using a Wix 51010 filter....on the top lid of this cannister housing is says to use a WIX PC-10 filter and per the Wix Filter web site cross reference, the Wix 51010 filter is the replacement for the old PC-10. -

46 P15 Canister oil filter hose routing question

3046moparcoupe replied to 3046moparcoupe's topic in P15-D24 Forum

Thanks Rallyace. That would explain the clearance issue. I'll plumb this all back in with hard metal lines. I appreciate it. -

Reaching out to my forum members again for clarification. I appreciate it guys. Today I figured I'd mount up my re-conditioned starter and generator to allow for getting the coiled up generator leads routed and terminated and I've got some honking 2/0 battery and ground cables, terminals, connectors, etc.. sitting here waiting to go on the car. Stabbed the starter, bolted it up, and was immediately reminded of something I had noticed and since forgotten about , once I started taking this car apart a few years back. One of the in and out oil lines between the block and the canister type oil filter, tries to lay on and rub the back of the starter. It's the line that comes out of the bottom center of the oil filter. I experimented with loosening the clamp that holds the filter housing and tried rotating the canister clockwise - which (if I went far enough) would produce a small clearance between the hose and the rear of the starter, but then the upper hose is now over in the way of the shift linkage,... I messed with it for a while, thinking I might could find that exact right sweet spot (by rotating it both directions and also moving the entire canister up and down in the circular clamp that holds it in place to the block. I also loosened both of the nuts that attach the Cannister brkt/clamp to the block to make sure the entire bracket was as far towards the front of the car as possible. (which it was, I did however notice that both holes in the Cannister mounting to engine block bracket were oblong shaped to allow for some forward/backward movement...my 1st thought was that it would be easy enough to increase the width of these oblong holes a bit and I could gain some clearance that way),..if nothing else presents itself to remedy this.. Anyway - it got dark thirty on me, and as I was putting tools up and staring at this thing a bit, I began to wonder if possible the entire assembly should be turned so that the hoses are actually pointing more towards the driver inner fender ? This would get them away from the shift linkage and the rear of the starter....hummmmm ?? I doubt these are the original hoses, who knows whats been put on here ?? Being somewhat outta gas, and with it being dark thirty, I came inside and grabbed my camera and took a picture of the way this setup looked when I got the car, how it exists today,.. and I have attached the pic to this post. Could any of you P15 folks out there possible reply with a picture of how this setup is supposed to look ? or if a picture isn't possible, an explanation of how your hoses are routed would be great as well. In looking at these hoses tonight, I noticed that the one that's been laying on the rear of the starter is starting to show some signs of cracking where it bends, so I'll go ahead and replace them both. Might be a good time to look into getting rid of the canister filter assembly and going with a modern style spin on filter conversion. I've got the dual heater setup, so there's really no room on the firewall and my driver side inner fender has really become congested with electrical.....I should be able to build a bracket that would allow the spin on filter base to mount up to the block where the old cannister filter mounted, anyway - any help, direction, pictures related to either the correct hose routing for the old style canister filter, or in regards to converting to a modern spin on style filter would be a lot of help. Thanks again for your time and all the help. Steve

-

My new headlight/turnsignal harness wires are extended up past the inner fenders, through the new terminal blocks, and I have the wires coiled up and laying in the splash tray area of sheet metal. under the core support where they are waiting for the day when they'll connect up to the headlights and turn signals. I left myself plenty of wire coming off of the t-blks to reach the headlights and turn signals, so it would seem like it would be better to avoid another splice anywhere between the t-blks and the lights themselves...(just another place for possible corrosion,etc...course if I'm overlooking something here in my thinking about not having a splice,..please chime in and set me straight on this)... So I'm thinking I'm gonna need to get the connectors, the connector pins that will be crimped and inserted into the connectors, and a good hand crimping tool to get the job done. I've learned that all crimping tools are not equal, and with this being one of the higher amp draws areas of the electrical system (still a 6v system), I would appreciate input from my forum members on this. From what I've been able to try and learn about this process, from reading on this computer...I't appears as though I'm looking at the old standard h4 (9003) 3 prong sealed beam type headlight connector plug.....(some are plastic, and some are ceramic (which I believe is necessary to handle the higher heat of the halogen type bulbs),...again, please correct me if I'm wrong on this,...anyway - these connectors aren't expensive, so if it's wise to go with the ceramic due to longevity/quality/etc...that would make sense to me, even if I'm planning on using standard sealed beam headlight bulbs.\ Also in studying the pins, I have found that there are some steel pins available that are rated for the heavier 10-12 awg wire, (as all of the brass pins I saw were rated for 14-16 awg wire only),...so I need to take that into consideration to make sure that my pins are adequate to handle the load and wire size demands......I did also see where the pins are available in both female and male configurations. I don't believe I've ever seen a standard sealed beam bulb that didn't have 3 male spades extending out from the rear of the bulb, but this part seems straight forward easy peezy enough, just make sure when I purchase my bulbs that they do have male spades and order the females,.....one thing however on the connector pins themselves, they seem to be offered in both open end and locking type, and I believe the ones I found that were rated for 10-12 awg wire were only available in the locking tab type,...(is this a concern or problem ? ) lastly, on the crimper itself,...from what I've read, I believe what I need is referred to as an "open barrel type crimper" ? And if this is the correct description for the tool, One that will handle 10-12awg crimps (yellow). of which one groove will crimp the pin to the insulation and one groove will crimp the pin to the conductor when you go through the crimping process two times for each wire to be crimped down to the pin. I suppose every part/piece is as critical as the other in ending up with a job well done that will last and work as it should...( Certainly the crimper tool itself is of major importance)..I've looked at some of what is out there and fortunately the open barrel type crimpers don't appear to be real expensive, so yeah !! for that :). I would really appreciate any input for my forum members regarding this process, in respect to all the pieces and parts as described above, I know Thomas and Betts is a really good name in regards to crimpers, etc...again any help and info would be much appreciated...and I would like to purchase parts and a tool that will do the job as well as is possible for an old pudding head like myself Thanks again for all the help and direction. Steve