-

Posts

89 -

Joined

-

Last visited

-

Days Won

1

bluebanshee last won the day on April 30 2019

bluebanshee had the most liked content!

Reputation

23 ExcellentProfile Information

-

Gender

Not Telling

-

Location

PA

-

My Project Cars

1957 D-100

Converted

-

Location

PA

-

Interests

antique motorcycles

-

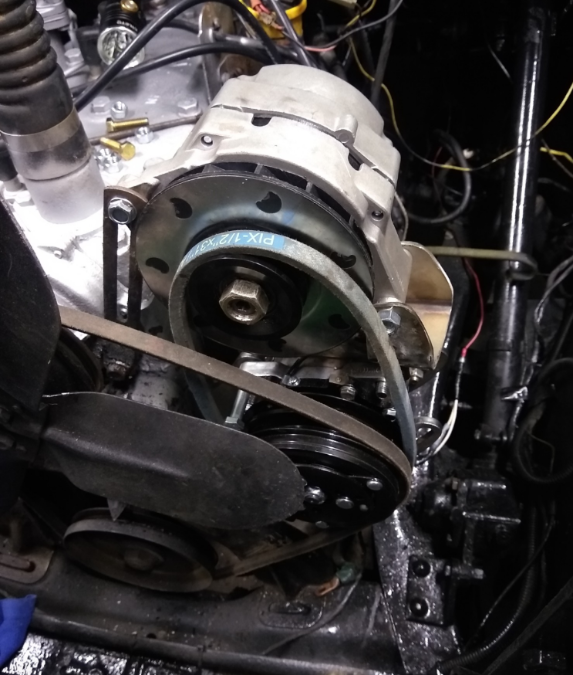

Here is what I did but put the compressor on the bottom. Obviously had to get the correct belt once I could take a measurement.

-

I did a similar AC only under dash Old Air setup. Can check my thread in the truck forum.

-

I noticed the same thing with mine. I don't want to snug them too much with 64 year old threads. I used Teflon pipe dope to stop the leak.

-

Added 16" fan on manual and AC high pressure switch off its own relay. I consider the AC project done. It will now hold 44F idling in the garage at 70 ambient. Water pump is seeping so that's a project for Thursday.

-

90 out today and on the highway temp gauge is in the middle and the air coming out of the evap is mid 40s. Ended up ordering a 16 electric fan which will be on both a pressure switch and toggle via a relay. Added 5/16 closed cell insulation to the floor and ceiling so that should help a good bit. Might not freeze you out like a new car but is nice and comfortable when it's 90 out.

-

I have dual carbs and dual exhaust on my 230 (truck) with knock off glass packs. It's not very loud at all with no baffling. If I was to do it over again I'd start off without any muffler/glass pack. Slightly disappointed at the sound or lack of.

-

Replaced my 12si with a local 10si one wire for $52 +$33 core charge so I got to take it for a test run. As a side note I have 14.5v at idle without having to rev at all to excite the alternator. Lights don't dim a bit at idle when fan is kicked on high. Low 70s sitting idle in the garage for 20 minutes the AC comes out at 50. 30mph 1/4 mile loop the air coming out was in the low 40s. Won't know til it gets 85+ how things work. Temp gauge was near the upper end of normal. The needle was parallel with the right side of the A in HEAT. head temp was about 185 via IR temp gun. This is a bit hotter than it normally runs but my rad was about 3" low too. I'll do a Dawn soap flush and add some water wetter and see if there is an improvement. Still need to add the drain tube on the evap. It produces a significant amount of water.

-

Thanks. Looking to habe a clean install like that. I'm fairly certain mine is on the same port off the block which would make 0 sense.

-

Have cold air blowing but alt isn't charging. Need to try a power wire to see if it excites. Need to clean up wiring, add support bracket to the blower and the drain lines. Seems to blow pretty cold. I don't think electric fans are needed. I didn't get over 200psi sitting idle in the garage for 20 mins. At 900rpm idle it will drop to about 650-700 RPM when pump kicks on. I do like a higher idle that spec's to help on all the hills here.

-

I didn't contact them but that's the generic universal kit that came up on their site. You can pick which compressor and condenser size you want. I got a trinary pressure switch if I need to add an electric fan later. I think the condenser is 21 wide by 16 tall and fits pretty well. Evap, condenser and pump all came either under vacuum or pressure, I couldn't tell. Overall kit seems good but did buy a $150 crimper for the lines and the ends are not complete.

-

Mind sharing what size fittings you used? PO on mine used ugly hydraulic lines that might be sleeping.

-

Hoses are done and partial vacuum applied. Still have all the related wiring to do plus for the alternator. If no leaks I may get it charged up tomorrow.

-

I got universal brackets for the compressor but the alternator brackets are from stainless plate I had cut with a wafer wheel. It's not perfect because I eye balled most of it and didn't have a marker lol.

-