-

Posts

8 -

Joined

-

Last visited

Reputation

0 NeutralProfile Information

-

Gender

Male

-

Location

Viola, Idaho

-

Interests

old iron, thinking outside the box, conservation, pathology, regional geology.

-

My Project Cars

1947 WFM-38, 1968 C-500, and a few other non Mopar makes.

Contact Methods

-

Biography

Suffering from an Old Iron Addiction

-

Occupation

Retired Forester

Converted

-

Location

Southeastern WA

-

Interests

Bustin' a Rusty Nut

Recent Profile Visitors

403 profile views

-

Dgrinnan, most of the Job Rated era Dodges that I've come across with sporting wiper motors other than the Trico vacuum units were vintage American Bosch units. They're a pretty substantial unit in situ, but compact enough to hide behind that wiper motor cover overhead. Some pics attached of a 12v unit (looks just like their 6v units; difference is in the part number, which also alludes to the degrees of swing) that was in my '48 FWD with a long shaft, you can see how they utilized a rheostat switch to change the speed to their liking. Also note how they used a switched unit on the passenger side, to halt that wiper, if it wasn't needed. My buddy installed one of those little modern units and had poor results, like you have experienced, I believe his was from VPW or Roberts, new arm, etc; very underwhelming. My personal solution was a cowl unit from a marine supplier; just be cautious about the body size relative to fitting it in the Dodge wiper actuator location. Hope your project ends with a simple solution! Brian A. (MBSoPaB)

-

Sounds like a plan! I look forward to seeing your final solution, and am sure other owners to come will appreciate it being shared here on the forum. About the only thing I feel compelled to add is that the shifter handle mounting is different between the COE (bolts to the base of the seat frame) and the conventional truck (bolts to a bracket on the transmission, under the floorboard). That may not have been visible between the initial batch of pics and the later ones. Otherwise, nothing fancy, all the ones I've dissected or documented have had simple angle iron and flat stock bracketry, clevise-type ends welded into straight lengths of ~ 5/8" or 3/4" OD tube. The engineering of the pivots and joints appears to be ~1:1, as far as input and output movement in the joints; if it takes 3" of linear movement at the axle to make the shift, then it's 3" of linear movement at the shifter under the floorboard. Hope your project goes smoothly! Brian A. (MBSoPaB)

-

-

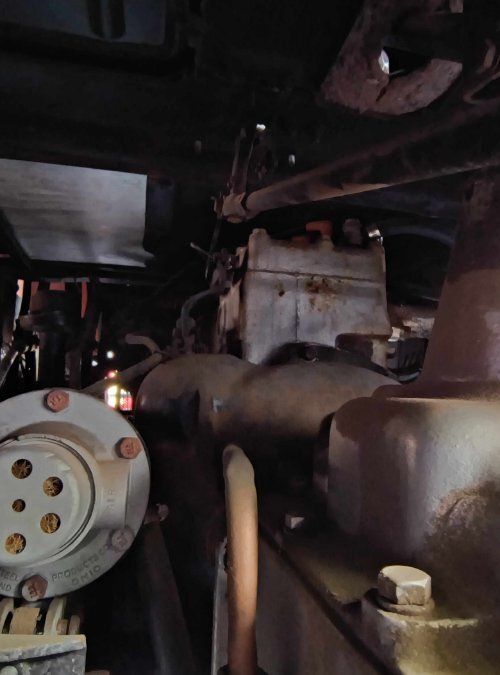

Tom, the following photos are from my buddy's '41 COE road tractor: the easiest thing in the yard to photograph without crawling around in the snow and slop. Best, Brian A.

-

Tom, here's a pic of the vacuum actuator from a '47 farm truck. Also, the lever in cab of a '41 mechanical 2-speed. I'll see if I have any pics or parts of the old mechanical I took out of my '42 WFMA ~15 years ago. They were brutally simple, nice formed steel hand lever, solid rod back to an intermediate dangling pivot from a frame crossmember, and another solid rod back to the mechanical 2-speed. I can get specific pics of the latter from my buddy's '41, but it sounds like you've some decisions to make before I go randomly flooding your thread with pics. Thoughts? Brian A. (MBSoPaB)

-

MBSoPaB started following New project, cloning an AoK dual carb intake for 23 inch heads

-

Lollipop cross section is pretty accurate! On the Bugs I've used it on, the head of the lollipop, or bead, lays a bit to one side as it is fitted between the panels. Like the letter P (or d or b, if that's the way you roll). The upholstery world opens up an even bigger can of worms/possibilities, with canvas or vinyl piping, varied colors and varied bead thicknesses. So many choices! Best, MBSoPaB

-

A possible suggestion on welting; in the Volkswagen air-cooled world they sell rolls for fender installation. Two basic versions, the fancier stuff with bolt holes pre-notched, or the cheaper stuff as just a roll that you notch yourself. An example: https://www.chirco.com/classic-vw-bug-beetle-black-fender-beading-fender-welt-all-years/ Like the previously mentioned inner tube or flat stock options, it's just held in place by compression, the fender bolted to the bed side. Just my ¢¢. Best, MBSoPaB

-

Jrod, like the others have said, keep fiddling with the bars and clocking the mounting bracket. My solution involved a couple of C-clamps and the welder, dedicating this mounting bracket to flathead sixes and eights. Although not the solution for everyone, it did permit me to mount the engine assembly closer to the center of gravity than my adjustable arm attempts. Please ignore the sub-par welds; fighting some cold 7018 rod. MBSoPaB