-

Posts

547 -

Joined

-

Last visited

Reputation

74 ExcellentProfile Information

-

Gender

Male

-

Location

West Covina, CA

-

Interests

Cars, baseball, drums, education

-

My Project Cars

1940 Desoto Coupe<br /><br /><br /><br />

1964 Cadillac

Contact Methods

-

Biography

From Los angeles California. Gain interested in working on cars in 1991 while in the military.

-

Occupation

College administrator

Converted

-

Location

West Covina,CA

-

Interests

Cars, Drums, Education

Recent Profile Visitors

3,916 profile views

-

Yes the torque converter had fins on the outside.

-

That's not the converter for this transmission. I just scrapped this transmission. I desperately needed the space and cleaning out due to most likely a divorce. Most folks here in So California switch to Cheby V8/auto trans drivetrain so not much demand for it here and too heavy to shift. Thank You all for the input I truly appreciate it.

-

-

40desoto started following Help identifying transmission

-

Hello seeking help confirming what this transmission is from and if it's of any value to anyone. I'm cleaning out my storage. Im almost positive that's it's from a 1954 Windsor with a 265 flathead on it but can't recall and if these are related parts to it.

-

40desoto started following Power Brakes with flathead six engine Vacuum inquiry , 41 Plymouth Coupe , Firewall mouting threat identification and 2 others

-

Hey Sniper, my apologies if I already inquired about this. Is there a way to add a non-power rack and pinion while keeping the flathead six in it? I Installed fatman dropped uprights with scarebird disk brakes and exchanged the steering arms from one side to the other. (flipped?) suprisingly they work without any more modification but now Im worried about bump steer because they are not exactly level to one another. Would a R&P setup correct this?

-

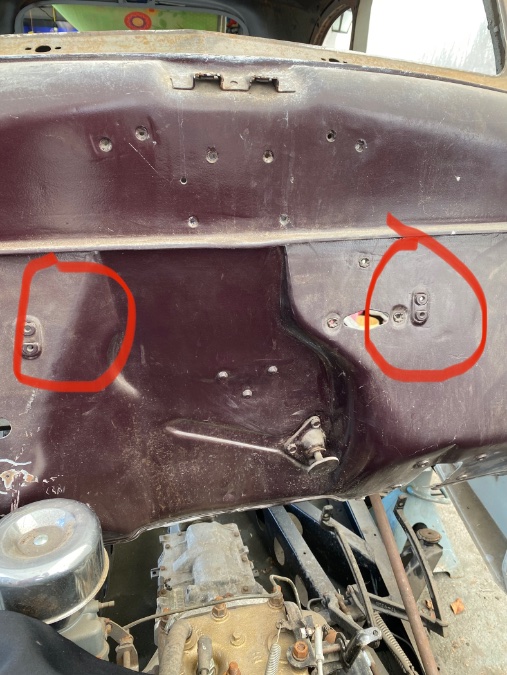

Thank You Andy. Thats what I was thinking but then noticed that they are perfectly symmetric to the center. Looks like the pictures I see of other 40's do not have them.

-

Thanks Rob, I did see other pictures of 1940's and didnt notice those mounts. Does appear that it's for anything structural.

-

Does anyone know what these bolt mounti g threats are for. Im about to replace my entire firewall and not sure what mounts here. They are symmetrical to the center so I'm assuming they might hold a part of the butterfly hood assembly? This is on a 1940 Desoto coupe

-

Thank You Greg! I know that I need at least 17 inches for the booster. I might give it a try's. Some folks have mentioned using the vacuum from a fuel pump. My fuel pump is installed but using an electric pump. Can my fuel pump be used exlusively for vacuum? is it ok to run it dry for extended periods?

-

Looks like scarebird is out of business. Does anyone know what year, make and model car the hubs scarebird used are out of? I believe they'll have to be machined down to fit the rotor to it.

-

Power Brakes with flathead six engine Vacuum inquiry

40desoto replied to 40desoto's topic in P15-D24 Forum

Thank You all for all the information. I'll be running it with a 265 and triple carb intake. I was thinking I can tap the intake to use as vacuum for the 7" booster. Not sure it this will produce enough vacuum (now after reading the responds- too much vacuum). Or pulling vacuum from the intake wil effect carburetor performance. -

is anybody running a power brake booster with a straight six engine? Does the engine produce enough vacuum to operate the brake booster? If so where are you grabbing vacuum from?

-

Thanks James, I'll look into that

-

Thank You Sniper, wondering if anyone has done the non-power one and how they liked it? specifically the limited turning radius based on what I read.

.thumb.jpeg.28cb36506a6b17cd30e7d4a22504384d.jpeg)