-

Posts

9,269 -

Joined

-

Last visited

-

Days Won

83

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Status Replies posted by Merle Coggins

-

Hey Merle, I was wondering if back in the day the tie rod end ball joints were the same dimension as the drag link ball joints? Could one buy tie rod end fittings from AutoZone and fit the ball joint to the old drag link? I find it har to believe they would have engineered a new part. What napa wants fro the drag link, I might as well buy another truck.....

-

Thanks much Merle for recommending Daves Repair in Allenton. I took the crank from my 230 to him today for grinding. He's retired now but still putzing around. Once the crank is done I'll be taking the block to him for machine work. The guy's really laid back, reasonable and can do the job. He knows his way around these engines and I have confidence in his abilities unlike local machine shops I contacted. Thanks again.

-

-

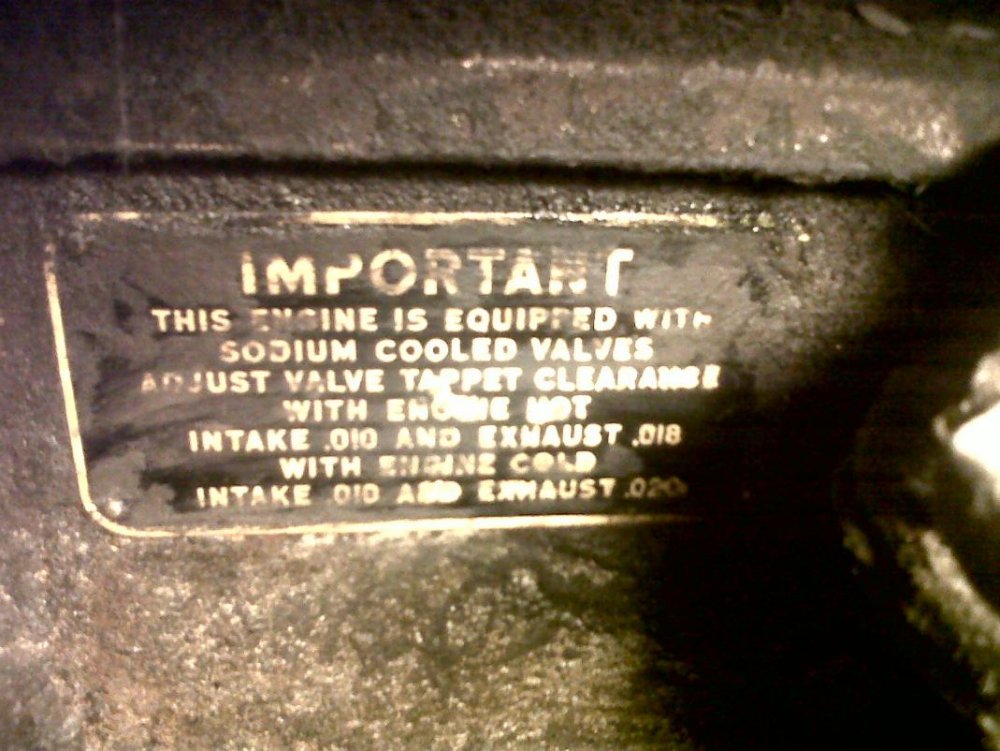

As it shows in that manual, get the engine up to operating temperature and measure/adjust the valves with the engine running at idle. You should be able to get everything ready when the engine is cold, remove covers and etc. Then let the engine run until it gets good and warm. You shouldn't loose much oil from the open covers if it just idles. Then use feeler gauges to slip in between the tappet and valve stem while it's running. If they are too tight you won't be able to get the feeler gauge to go in. If it is too loose it may reduce noise when inserted. You can actually feel a slight resistance when it's adjusted properly.

I don't have any other written instructions besides what's in the manual that you have. You just need to get in there and try it. It's not too hard once you get going. I will recommend long tappet wrenches if you have them. Also longer tappet feeler gauges help. These help keep your hands away from the heat a little more. I would also wear a good pair of gloves. You will find that your knuckles will get pretty hot at times. Just take it slow and you'll be fine.

-