-

Posts

1,377 -

Joined

-

Last visited

-

Days Won

2

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Everything posted by 41/53dodges

-

Another option would be the modules used for trailer tail lights, meant to split the 3 signals (brake, left turn, right turn) to run 2 lights Zoro.com buyers 5423203 There's tons of different variations that do similar things too, I used one for my tail lights on the truck to also do turn signals.

-

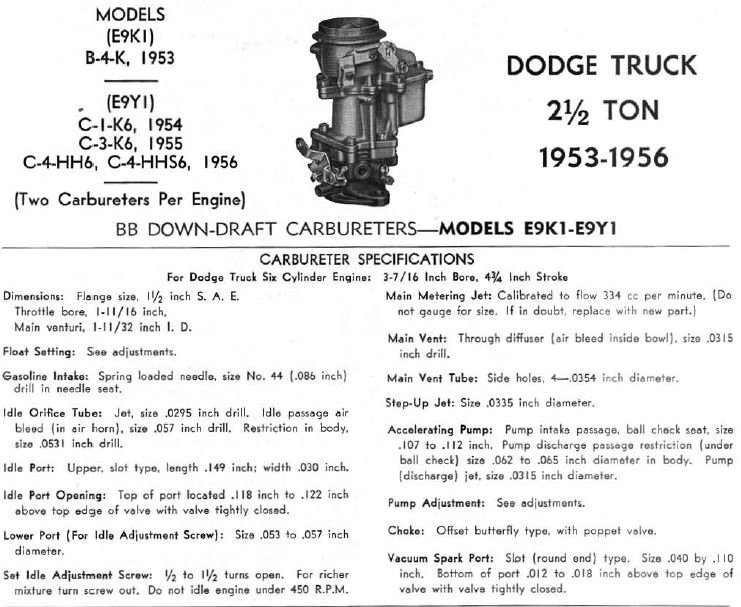

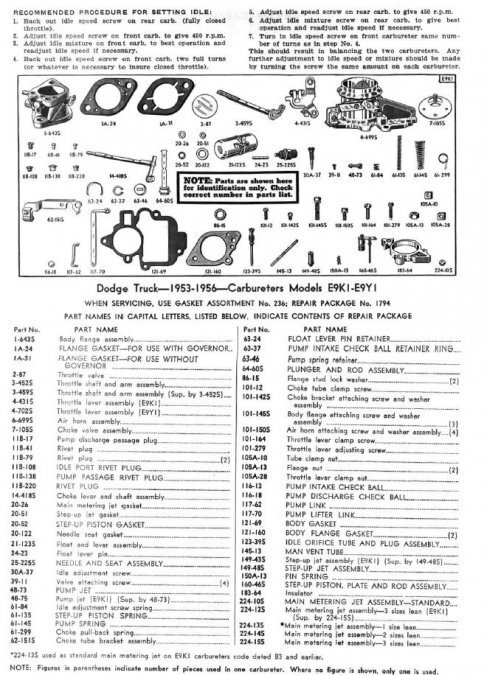

I believe the jets are indeed smaller, I don't recall what the exact size of the ETT1 was but I recall it being larger than the factory dual E9K1's I've got the full factory system from a 2-1/2 ton truck, sans the one missing (destroyed) carburetor. Haven't decided what I'm doing with it for exhaust, that'll definitely require some playing so it doesn't sounds like a rental car But, perhaps you're right. I'll throw on a pair of ETT1's and see what I get out of it, because worst I get is running crappy!

-

Good morning flathead truck gang! Looking for some insight on the factory dual manifolds, particularly the carbs. I picked up a set that was missing one of the E9Y1/E9K1 carbs a few years ago, been watching the usual sources for another but no luck so far. I've got a pile of ETT1's laying around, I believe the bore & venturi size are the same and jets are different. Can anyone confirm that's the case, and does anyone have any leads om the correct jets? Thanks guys, Josh

-

4X4 conversion of W series truck

41/53dodges replied to lostviking's topic in Mopar Flathead Truck Forum

I forget which of the FacePlant pages it is, but there's a guy doing almost exactly what you're thinking of. XJ Axles, engine, complete driveline. I'll have to see if I can find it. Fairly certain he chopped the firewall to make it fly. As for the T5 with the flatty, XJ's are driver side drop and S trucks are as well, Jeeps are passenger drop. Grab one with its case from a pre 1987 truck with a 2.8, or swap the tcase for one with a mechanical speedo Adapting the T5 to the engine ought to all be the same as normal, providing you use one with the Muncie pattern rather than the Ford pattern. That said, one hitch in that whole plan, the driver side tcase will probably hit your fuel tank. Maybe a wrangler T5 with its shorter tailhousing and some other case? One last thought- if you want to go old school 4x4, there's an M37 chassis in a boneyard near me. that'd be slow as anything, but cool nonetheless -

Making a replacement drag link (1953 B4-B)

41/53dodges replied to 41/53dodges's topic in Mopar Flathead Truck Forum

Thanks for the dimensions Los_Control, What I'd planned was to use the Mevotech joints at $42/pair, 11/16-18 tube weld bungs from Speedway at $32/pair, and then hunt down the DOM from the local steel supplier. Not the first nor wouldn't be the last I've made my own steering components, but I'm definitely looking into the DCM drag link. Been getting the "maintenance mode" screen from DCM the last few days, have to check that out whenever they get it up and running again. And, thanks for the thoughts and info guys! -

Hey guys, would anyone mind taking some dimensions for the original drag link for a half tonner? Specifically a 53' B4-B, but I believe the light trucks were mostly fairly similar. Mine was pretty mangled when I got it, so I'm just going to go ahead and make one. What I'm looking for is the center to center length, roughly how tall is the bend when laid on a table, and whether or not the standard tie rod ends fit the taper correctly? Thanks guys! Napa link for reference https://www.napaonline.com/en/p/RPC25594

-

T236-engine: Part of the 25inch family

41/53dodges replied to T236-Dose's topic in Mopar Flathead Truck Forum

The cool part of MoPar back in this era is how much stuff interchanged. Most everything will interchange for all the 25" MoPar flatheads (except crank & rods) So that motor is similar to American Dodge 1.5-2 5 ton trucks, 35?-53 Chrysler and DeSotos, and I think most Canadian production. As for parts, check Rock Auto. You can find most everything you need with some careful digging, I order stuff for a 53' Chrysler Windsor with a 265 for my 25" motor -

The most common swap is a Jeep Cherokee axle, it's approx. 1" narrower than stock, same ujoint, same driveshaft length, and same lug pattern as stock. Plus there's a mind boggling number of gear ratios and lockers available if you need a little extra traction. When I did mine, I just buzzed the old perches off and grabbed some trailer perches from farm and fleet

-

Saw that one, tried getting in contact with him a couple ways but he hasn't logged on in quite some time! Coincidentally my 265 has the same cam as him too!

-

Hey guys, been forever since I posted but I'm looking for some info Wondering if anyone knows anything about the old Saaty Meteor injectors. I picked a pair of em up at the Jefferson swap meet a month or so ago and have been scouring the internet for info, but nobody that has worked with em seems to still be around! So, does anyone know the ins and outs of these things? I've got a good general idea, but more information is always good. Was considering putting em on my warmed up 265 in my 53' Anyway, If anyone knows anything about em I'd appreciate sharing Thanks Josh

-

I've been running 12v on my factory 6v starter for years. Never had an issue with it, but I did tear it down to clean and lube it up a long time ago. That would be my first step. Also, check out the flywheel teeth while you've got the starter out. I've seen the starter gear wander back into the ring gear when the engine is running, you just hear this wierd "ching ching" type noise. Fun fact, they're wound to turn the same way regardless of polarity, or at least mine is.

-

Sticking valve in a rebuilt motor

41/53dodges replied to 41/53dodges's topic in Mopar Flathead Truck Forum

1st thing I checked, that would be awful to find. But nope, all clean inside. Went to do battle and hose it down with marvel the other day and the darn thing wouldn't stick! So I hosed em all down anyway and let it run awhile. -

Nut and Bolt sizes info on 38 DeSoto 25'' engine

41/53dodges replied to Dodgefran's topic in Mopar Flathead Truck Forum

Hi Fran, welcome go the group! Might I ask, is there a reason you don't want to use the original fasteners? If youre concerned about dirt, I soaked mine in jars of mineral spirits to shed all the crap from the years. That said, if you really want new hardware across the board it's all SAE stuff. Head bolts are kinda special, and there's a lot of different trains of thought on them. I reused mine, some people do studs, and some go to grade 8 bolts. I'd suggest something meant to be a head bolt, hence why I reused mine. Rod bolts are unique to my knowledge, so don't lose em or their washers & nuts. Same goes for the lifter covers. Probably something else I'm forgetting too -

Slight Engine Modifications

41/53dodges replied to thisoldtruck's topic in Mopar Flathead Truck Forum

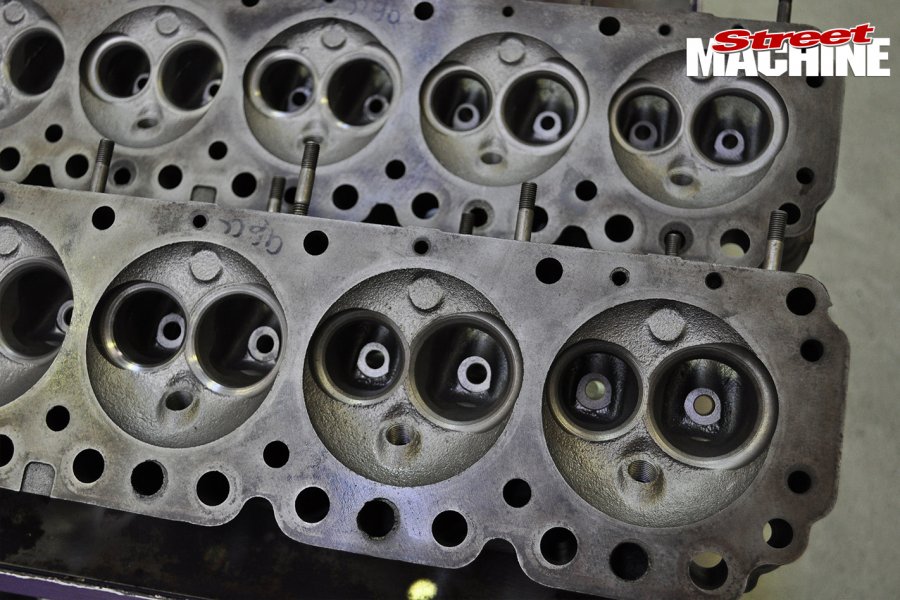

It sort of lived, but not in particular fashion. There was the Aussie 265 hemi, hardly related to ours though. Looks sort of like an AMC six with canted valves. They couldn't do the crossflow design of a normal hemi though, nor were the valves anywhere near the angle of the real hemis. That you could pull off with a stock flatty block, but bore size limits valve diameters pretty severely. -

Sticking valve in a rebuilt motor

41/53dodges replied to 41/53dodges's topic in Mopar Flathead Truck Forum

Fantabulous question, let me clarify. This block was out of a 47' dump truck, PO bought it as a remanned 237, put it to work for a few years and parked it back in the 80s. Buddy bought the truck and yanked the motor with big dreams, I stripped it down, cleaned up all the rust, honed all the cylinders, ground all the valve seats. New bearings all around, 265 crank, .060 Pistons, new valves to replace the broken ones, and an edgy 1/4 cam. In short, I didn't clearance the valve stems myself. I made sure they were good and tight. But I'm subscribing to the rust theory, some marvel probably ought to do the trick, especially since it hasn't been up to operating temp since fall -

Slight Engine Modifications

41/53dodges replied to thisoldtruck's topic in Mopar Flathead Truck Forum

I actually worked on a design project like this in college, although more performance oriented. The big challenge was trying to work with the canted valves and pushrods of the hemi with the straight vertical valves of the flathead. Never did figure how to do that with an unmodified block -

Sticking valve in a rebuilt motor

41/53dodges replied to 41/53dodges's topic in Mopar Flathead Truck Forum

Pretty much! I think I measured like a whopping 1/32 difference in the intake bore. Which I why I've got an Ellis intake on hand, whenever I find all the stuff to get it together. -

Sticking valve in a rebuilt motor

41/53dodges replied to 41/53dodges's topic in Mopar Flathead Truck Forum

They're not a whole lot different from standard truck manifolds, but the intake is a tiny bit bigger and the exhaust is a huge 2.5" 4 bolt dump. Would be very good for a turbo... Here's a picture from when I finished the motor -

Sticking valve in a rebuilt motor

41/53dodges replied to 41/53dodges's topic in Mopar Flathead Truck Forum

Heat riser flap was staked in the open position, since the spring was gone. Trucks got 2.5 ton school bus manifolds, so 2.5" straight back exhaust and a glasspack. But that does make me wonder if a mouse might have climbed up in there and built a home... Thing doesn't sound constricted when it runs on all 6, but definitely food for thought... -

Sticking valve in a rebuilt motor

41/53dodges replied to 41/53dodges's topic in Mopar Flathead Truck Forum

Nope, already popped the side cover off to check! That was my first thought as well. Best I can figure, the exhaust charge from the other cylinders pressurizes the one with the stuck exhaust valve through the whole cycle, including intake. It seems to blow back and pollute the charge for #2 as well, because that cylinder goes down at the same time but maintains spark and compression. Wierd eh? -

Sticking valve in a rebuilt motor

41/53dodges replied to 41/53dodges's topic in Mopar Flathead Truck Forum

Thanks for the thoughts guys, I was kinda figuring it had to do with getting damp and probably rusting up the stem. I'll have to try the marvel mystery oil, or I've got some outboard fogging oil in the garage. The big pain in the rear is that it's the exhaust valve, so it just keeps blowing back through the intake! Funny how that works... -

Good morning guys, been forever since I posted a new topic but this one's got me stumped. Last winter I built up a 265 Spitfire engine for my B4b, used an edgy cam, shaved head, and heavy truck manifolds for now. Ran like a Swiss watch. I parked it in fall just before the snow started but usually light it up every month or so. I've noticed that when I start it, #1 exhaust valve keeps hanging open, usually it will come free on it's own accord once it warms up but this time no dice. Had to pry it back down with a screwdriver, and it stuck again immediately. Even tried running it and being the valve spring. Darn thing just sticks up, and makes it sound like a messed up Harley! Has anyone seen something like this before? Josh

-

1948 dodge pilot house dually!

41/53dodges replied to TuckerJohnson's topic in Mopar Flathead Truck Forum

Check out Rock Auto for engine parts, it's easier if you search for Chrysler cars though (I usually search 1953 Chrysler Windsor), otherwise vintage power wagons and eBay are your friends. As for those wheels, there's nothing wrong with the original Dodge split rings, just make sure they're not the widowmakers or they're not too rotten. If you still want to get rid of em, there were 22.5 wheels with the 5 lug pattern, I've got a couple myself -

What size tires are you running? I have 3.55s and 215-85r16s (about 30" dia.) and it's alright, you'd definitely want some smaller tires with 3.07s. By my countilations, about a 26" wheel would get you 2400 rpm @ 60mph

-

Well, question number A what do you want out of the truck and why you want to swap? Not really such a thing as an easy swap, everything requires some level of work