-

Posts

115 -

Joined

-

Last visited

-

Days Won

2

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Everything posted by rekbender

-

I just checked with Falcon Performance. The fellow said Sealed Power 37P60 is available as a single piston from JEGS for $33.99. You'd probably have to buy a full set of rings.

-

If you get desperate, I have five used .060 over pistons from a 218 parts engine. They are old Conformatic pistons, total weight with rings, pin and circlips is 642 grams. They seem to be usable. I'll send you one if you think you could use it.

-

-

One more bit of information to add here. While driving the car Friday, I had an "aha" moment concerning the operation of the Auto Stop. To make an uphill start with the Auto Stop engaged, I'd been letting the clutch out to near engagement and then pushing the accelerator to release the valve and go. There was still that brief period while the rpm came up the I'd roll backward a little. Then I realized that if I pushed and held the shift lever button down again before stepping on the gas, I could bring the rpm up without any roll backward as the button circuit keeps the valve activated by it's parallel ground circuit. Very clever on the part of the designers. Release the button when the engine takes up the load and voila - no rolling. I'll bet this procedure was included on the missing owner/operator card. This area of southern Ohio can be really hiily in places and now I'm wondering why this accessory wasn't more popular, or was it?

-

I'm turning 70 tomorrow and find myself in great company here. A wonderful neighbor gave me my very first car, a two tone green 1954 Dodge Coronet Red Ram 4 door in 1965. That was one tough machine. I gave it to a true friend and my first automotive mentor when I was drafted in 1966, and it ended up in a figure 8 race at Glen Este Speedway. My first "antique" car was a derelict $100.00 1948 Chevrolet sedan delivery purchased from a local AMC dealer, Harry and Carl Rambler, in 1969. They'd put it right out in front with bunting and flags as a joke, but the styling just blew me away. It was a tired old Grandin Hardware Store veteran, and with a Jasper rebuilt engine, an 8 volt battery and new tires, it became my daily driver for about three years. Next came a 1950 Plymouth Deluxe 2 door fastback, then a 1937 PT50 as a shop truck in the early 1980's, a 1936 Plymouth P2 coupe in 2009, and a 1935 Plymouth PJ coupe in 2011 which I sold to purchase my 1949 P18 Special Deluxe convertible this spring. Despite lots of other cars in between, I keep coming back to Plymouth flatheads.

-

ANSWERED photobucket restrictions due to 3rd party hosting

rekbender replied to JBNeal's topic in Off Topic (OT)

Maybe this is a dumb question from an old man, but why save photos on some remote site? I have over 10,000 photos on my 9 year old Imac backed up on a $45.00 hard drive from Walmart (actually two hard external drives just in case ). The computer did crash two years ago, but the back up saved everything. If sized correctly, my pictures upload with no problems. There must be an advantage - what am I missing here? Thanks. -

Beautiful car, great color and thanks for the mesage. This is the front bracket on my P18. I don't know if it is correct or not. It kind of fits the ripple bumper and seems to put the plate in the right position.

-

Found this at last fall's Pumpkin Run Nats. Seems to be a near relative to the one on knuckleharley's '48. I paid $25.00 for it - yours for $25.00 and postage.

-

OLDMOPAR84, an ebay seller called vintageamericanpartscompany listed the item as a buy it now for $385.00 with a make offer option. I'm a pushover for accessories like this and was surprised when they accepted my low offer. I spent a bunch of time freeing the solenoid valve armature and had to buy 100 ball bearings to get the correct .281" steel ball for the check valve. I dis-assembled and cleaned the contacts in both the shift lever and throttle switch, as well as repairing the wiring. I decided not to use the ancient flexible brake hose included in the parts. It's really cool!

-

I couldn't get the last two pictures to upload, so here's the last two. I tried to quote HotRodTractor but didd something wrong.

-

-

Are these the ones you need? These are from a 1950 218. PM me your address and I'll put them in the mail tomorrow.

-

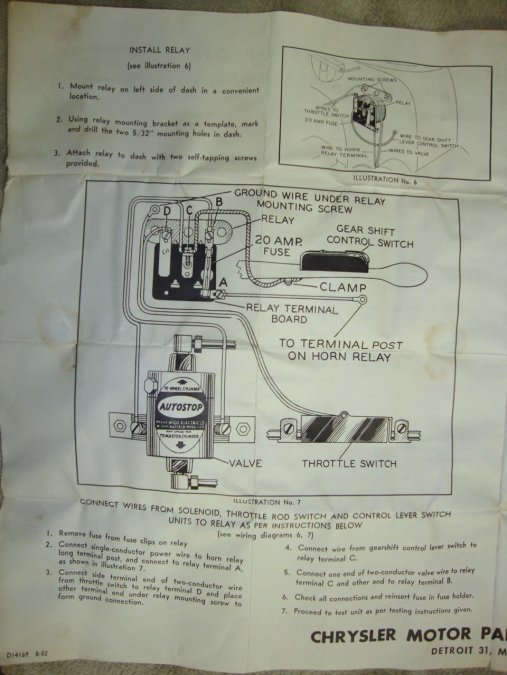

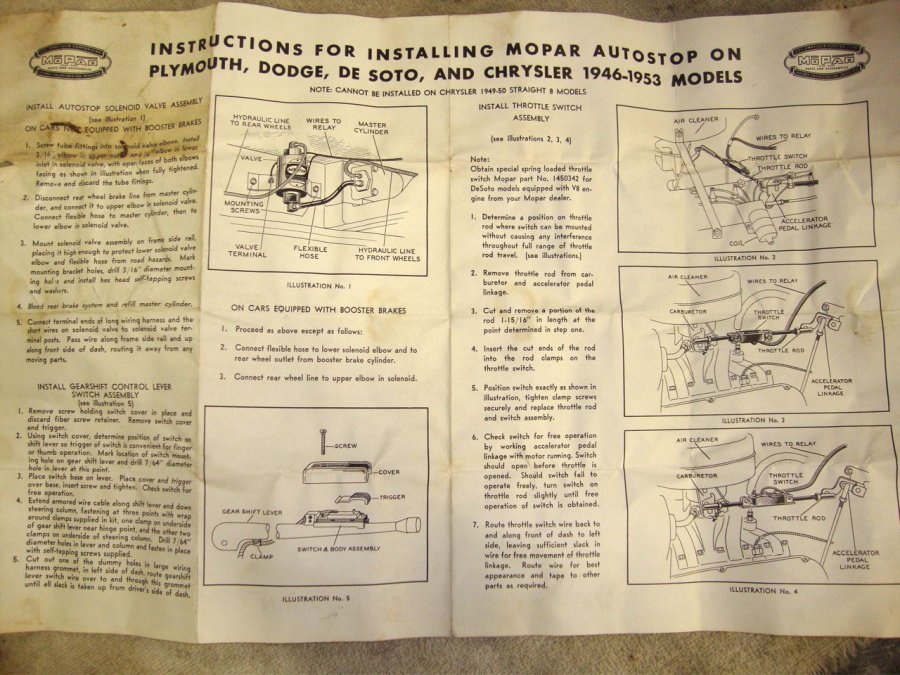

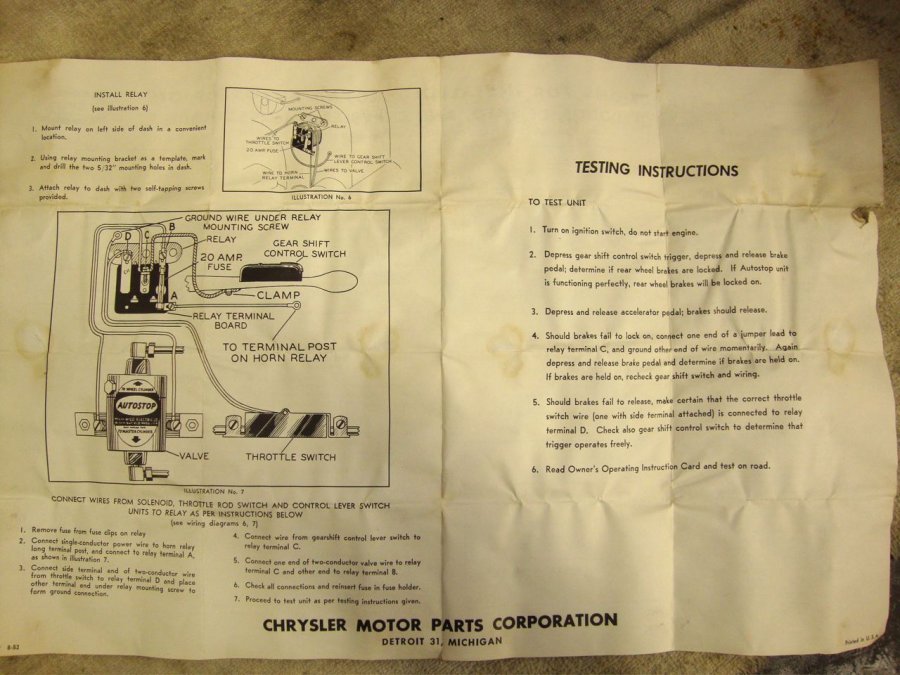

There isn't much information available on the MOPAR Auto Stop accessory hill holder offered in the early 1950's, so I thought I'd add a little more here. My Auto Stop was listed on Ebay a month ago and appeared complete. The seller accepted what I thought was a reasonable offer so I took a chance and bought it. It was all there, right down to the little envelope that included the installation pieces, missing only the driver instruction card. It even included an extra throttle switch for early V8 equipped cars and an extra gear shift lever switch. Think of it as a 6 volt line lock or roll control. It consists of a gear shift lever button (looks like a door bell button) with an armored cable, a control relay, a throttle linkage switch, and the 6 volt solenoid valve. The gear shift lever switch monetarily completes the circuit through the rear wheel brake solenoid valve and activates the control relay on the fire wall at the same time. The solenoid valve then remains closed until the accelerator pedal is depressed. When brake fluid is the locked under pressure to the rear wheels, a parallel fluid circuit with a ball check in the solenoid valve allows more fluid to enter the circuit if more pressure is needed to hold the car on a steep hill, or if you simply want to activate the Auto Stop before stopping completely. Now you can take your foot off the brake pedal and prepare for the up hill start. An over the center type switch is placed in the throttle linkage and the pressure of the throttle return spring on the linkage keeps it closed. The control relay is grounded through this throttle switch so when the gas pedal is pushed, pressure on the linkage is decreased and the throttle switch opens. The control relay de-activates and you're on your way. You, the driver, are required to have the clutch pedal out near the friction point, and bring the engine RPM up quickly to avoid rolling backward. I've been practicing this week and have just about mastered the technique. For some reason it feels counter-intuitive at first, but not for long. My biggest problem has been remembering to shift into low gear after I push the shift lever button to set the Auto Stop. It's hard for an old dog to master a new trick.

-

Call Dennis at DME Transmission Parts - 606 237 6648. I've purchased parts for two '36's and a '37 from him. He's had everything I've needed ( drive pinion, counter shaft, cluster gear, synchronizer assy, small parts, bearings, etc.). I also have a nice, but untested '37 transmission I bought 35 years ago and never used, but you'd probably rather rebuild yours.

-

ANSWERED Interesting photos I have run across.

rekbender replied to Don Coatney's topic in Off Topic (OT)

Found a photo of this on on Ebay, don't know if it's been posted before. Here's a link to more of the story. http://theoldmotor.com/?p=163296 -

The extra hole doesn't seem to have anything to do with the hood hinge. There is a stop on the hinge arm that the coiled spring hooks over that limits how far the hood opens. Could this lever be bent or frozen so the hood only opens partially? I would loosen the three nuts (two are up under the dash) that hold the hinge to the cowl and attempt to swing the whole hinge assy. upward. I've never tried this and don't know if this is even possible with this design or whether the hood could then be made to fit the opening. Just my thoughts.

-

Need measures 14-17-1 lever.

rekbender replied to Fernando Mendes's topic in Mopar Flathead Truck Forum

-

I have one of these on my '49. For the price, it is well made and fit with only a little trimming, but it's not an exact reproduction You'll have to swap the sheet metal flange from your old duct at the fire wall and make a cork gasket. There is a fellow on the Plymouth Bulletin who makes what appears to be a really nice reproduction for $149.00. You can find it here: http://www.plymouthbulletin.com/market/market.pdf

-

The truck and the contents of the dealership had been moved from Indiana to a defunct country club property in northern KY when I bought it. I thought the stencil may have been an Indiana state requirement or maybe something from the war years. I should have bought the parts inventory as well.

-

Sometimes I fell old enough and dumb enough to have done that. But it was a one owner ( a former Packard dealership service truck) when I found it . I as the second owner.

-

I'd like to have the one owner, unrestored 1937 Plymouth PT50 pickup that I sold around 1983. I still miss that truck.

-

I am trying to figure out how to properly stow the jack, base, and tire wrench in the trunk of my recently purchased 1949 Plymouth convertible. The tire is bolted to the floor, and the jack clips into a couple of brackets on the right side of the trunk, in front of the top motor. Did Plymouth just leave the rest loose or under the tire? Any information would be great.

-

Hi, I just tried the trunk lock on my '36 Plymouth coupe - it may be the same design internally as your Dodge. One full turn of the key clockwise locks the trunk (actually the handle rotates freely so the trunk can't be opened) and one full turn counter clockwise unlocks the trunk (now the handle is connected to the latch and the trunk may be opened). I removed the lock cylinder from a spare '36 Plymouth trunk handle to see whats in there. My lock cylinder looks similar to yours. The little tab on the bottom of the lock cylinder engages the disc with the u-shaped slot down in the handle and rotates it when the key is turned. As the disc turns it pushes a little pawl in and out of engagement and allows the handle to turn freely or not. It looks like everything is pressed together and then peened in place. I hope this is of some help.

-

-

Hope your leak is fixed. I attempted to use Dorman steel concave plug #550-023 this winter on a '50 Dodge engine this winter. Some were .015" oversize (1.6240") and almost impossible to start. Pressure testing the long block at with air and soap suds at 20 psi showed tiny leaks around 3 plugs and I could not get them to seal. The block had been professionally cleaned but some of the cavities weren't perfectly smooth any longer. I removed the steel plugs and ordered Dorman brass concave plug #560-023. They consistently measured 1.632" to 1.635" went in with snugly with no problems. I will not use steel plugs again. The brass plugs are nice and thick, and deform more easily. Just my 2¢.