-

Posts

7 -

Joined

-

Last visited

Reputation

2 NeutralProfile Information

-

Gender

Male

-

My Project Cars

1955 Dodge C-3 B8

Contact Methods

-

Biography

All things old are cool, especially old trucks, old cameras and old vinyl!

-

Occupation

Salt mines for a few more years...

Converted

-

Location

Milwaukee, WI

-

Interests

film photography, darkroom, classic car restoration

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I should add, I did put it in 2nd while turned off. Clutch pedal depressed, she lurches forward.

- 1 reply

-

- clutch

- clutch disc

-

(and 3 more)

Tagged with:

-

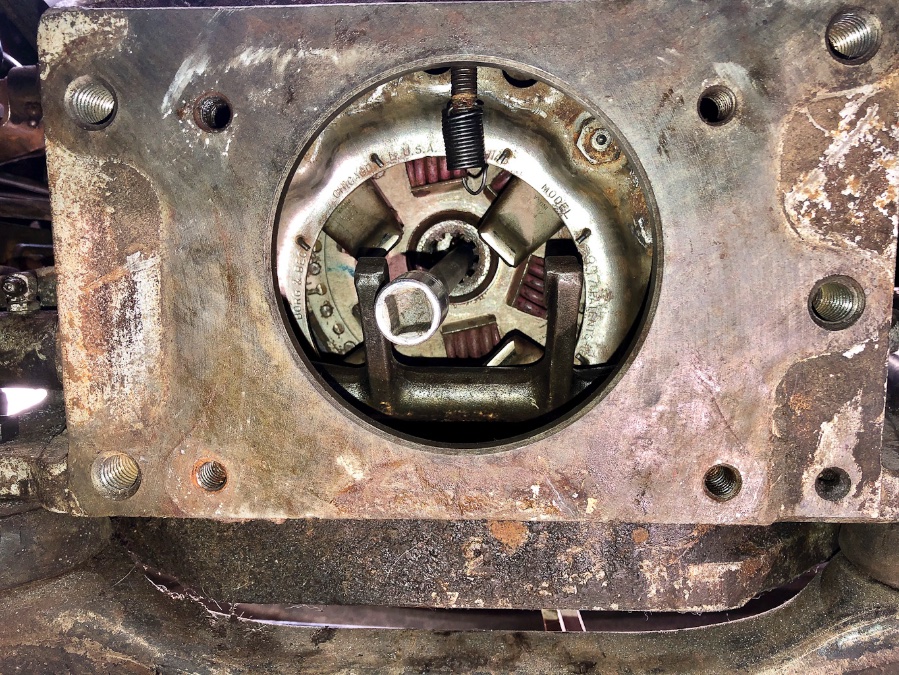

I cleaned and reinstalled my clutch on my '55 C3 B8. Today, I adjusted the clutch linkage via the turn buckle, plenty of threads each way. However, the column shift doesn't want to go into gear (even 2nd) while engine is running and the pedal feels fairly light (or soft), like I can press down all the way to the floor with my hand. How heavy (or light) is this clutch supposed to feel? I have a feeling the pressure plate might be shot. I could see the throwout bearing engage with the pressure plate springs (four of them on my model), so there is some articulation there. On a side note, I got the box mocked back up and set on the frame today. Friday, I rewired the negative from coil to distributor, as points weren't firing. It's always something... Any insight on the clutch is appreciated, thanks! Havs

- 1 reply

-

- clutch

- clutch disc

-

(and 3 more)

Tagged with:

-

1954 1/2 ton exhaust system recommendations

Havs replied to WPVT's topic in Mopar Flathead Truck Forum

I used Waldron Exhaust in Michigan. I called them, a real person answers the phone. I told them I wanted only the original y-pipe for my '55 241cid (which runs under the oil pan, single exhaust back out pass side) as mine was rusted out. They sent the part in a few days, and they have complete systems too. I will use them again on future projects. http://waldronexhaust.com -

Got her back together today. I found it did help to unbolt the yoke, allowing me to slip yoke to the left and out of way, then get throwout bearing back in place. It was a pain to hook up the spring on top of the bearing and keep it from falling off! But it articulates and seems to engage those clutch levers. Definitely getting the alignment tool for next time I do this. Now tomorrow, try to get her running in this cold and test on her...

-

Ahh, just catching up on these. Yes this might be the key! I'm going to reconnect that clutch linkage and see if depressing the pedal moves those levers slightly , then the throwout should slip right in! Thanks guys!

-

Thanks for the replies so far! I have a spare tranny 3spd floor shifter, but I really don't want to tear into it for the shaft. I will make a point of finding a spare shaft or getting the plastic one for next time's tear down. I've got the clutch linkage completely disconnected, so I will try to bolt up the pressure plate tomorrow AM and see if I can slip in that throwout bearing back in. I will also unbolt the yoke from the housing to see if that gives me a little extra wiggle room. If this works, I should be able to do a shake down test drive around the neighborhood. Like my father-in-law said, see what breaks, leaks or falls off, then limp her back in!

-

Havs changed their profile photo

-

I'm hoping to get some help on my clutch reinstall. My clutch was really froze up on my 1955 C3 B8, the clutch disc plate was rusted solid onto the flywheel. After finally breaking it loose, I've cleaned it up and am trying to reinstall to test it, to see if I can get some miles out of it before sending for rebuild. The issue I'm running into is with getting the throwout bearing back in place. The clutch release levers don't seem to give me enough clearance; if I have the throwout bearing set in place, it causes clearance issues w/ the yoke in trying to get the pressure plate and disc up and in from underneath (engine is still in vehicle, she's jacked up to give me room to work). In theory, if I bolt up the pressure plate, this should draw it forward and give me some room to get the bearing set in? Or what am I missing? As you can see, I do not have the clutch alignment tool so I'm improvising. What have you more experienced Dodge guys done for workflow on an install or remedies for this? Thanks in advance!!