-

Posts

2,262 -

Joined

-

Last visited

-

Days Won

60

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Posts posted by Sam Buchanan

-

-

5 minutes ago, Booger said:

Back in the day (geezer) we 'tuned' these old cars by ear. Dwell meter?

Vacuum gauge? Turn the dizzy just so much. Play with mixture screw. And dont use Champion plugs

These are not Ferraris

Stop advancing the timing just before the engine pings while pulling that steep hill on the way to grandma's house.................

-

Your engine needs deworming!!

-

4 hours ago, Roofus said:

Bon, après avoir vérifié tout le circuit, je n'ai pas trouvé d'anomalie, mais en appuyant vraiment trés fort sur la pédale, celle-ci s'est brutalement enfoncée et est restée en bas, il s'avère que la tige de poussée du maitre cylindre s'est détachée de la pédale, car pas assez de filetage engagé…

Après avoir tout remis en place, j'ai constaté une fermeté inédite de la pédale, je suis allé faire un test routier et ça fonctionne maintenant parfaitement.

Je pense que le circuit n'était pas purgé correctement et que l'incident de la tige de poussée a fait remonter les bulles dans le réservoir.

Well, after checking the whole circuit, I did not find any anomaly, but by pressing really very strong on the pedal, it has suddenly sunk and remained at the bottom, it turns out that the stemMaster cylinder’s push detached from the pedal, because not enough hired thread…

After having put everything back in place, I noticed an unprecedented firmness of the pedal, I went to do a road test and it now works perfectly.

I think that the circuit was not purged properly and that the thrust stem incident raised the bubbles in the tank.

Excellent! We know what you are describing. ?

-

4 hours ago, stukamensch said:

It's show condition allegedly and runs and drives great and everytging works except the wipers.

Excellent. That changes the character of your original (unedited) post.

Some might be concerned about whether or not non-detergent oil is in the engine, be good to find as much recent service history as possible.

Enjoy your new ride!

P.S. Your first purchase is one of these:

https://www.rockauto.com/en/moreinfo.php?pk=10593924&cc=1486874&pt=10335&jsn=381

-

1

1

-

-

1 hour ago, RobertKB said:

The machinist I have had do some work on my cars has absolutely no time for speedi-sleeves. Says they are way too thin but may be ok for vehicles that get low miles but not daily runners. He wouldn’t put a Speedi-sleeve on the same hub as shown above. He machined the hub and made his own thicker sleeve to bring it back to original specs. Very reasonable on price as he likes working on old car stuff. I’m lucky although I think he has retired now. He had his own business for years but sold out to a big outfit and ran their shop. He did small jobs like mine on his own time. He’s a real character and very proud of his trade!

I think you just explained why it is not practical to get the machine work you described in most instances today. Machining in a commercial shop is expensive even if you can get someone to do this small a job. You had this done some time in the past by someone who enjoyed doing this on his own time. That doesn't represent reality for most of us now.

This is a similar situation to the solder sleeves we discussed recently. Both of these technologies are proven and readily accepted in a variety of applications. However, some folks are hesitant to use technology with which they aren't familiar so they are convinced it is unsatisfactory. Fine......don't use it. The rest of us will take advantage of modern tech which is usually less expensive, doesn't require old-school techniques or expertise and yields satisfactory results. Personal choice.

By the way....my P15 has disc brakes, an alternator and a full-time electric fuel pump.......I don't hesitate to drive the car anytime, anywhere and it has proven to be extremely reliable. Old tech or new tech? ?

-

2

2

-

-

58 minutes ago, Plymouthy Adams said:

the wear groove does not bother me near as much as the crack that is shown.....the groove would be filled with epoxy and turned/polished before pressing the sleeve in place, that way the metal is backed solid.

We discussed this extensively when I first posted this photo 3+ years ago. It isn't a fatigue crack, it is corrosion and is only on the surface.

Yes, that is a worn hub and not that unusual for a bearing surface eroded by dust and a leather seal. But the Speedi-Sleeve is a good remedy. I filled the groove and "crack" with JB Weld prior to installing the sleeve.

-

20 minutes ago, andyd said:

I for one would be interested in seeing the adaption of a GM turbo hydro 350 trans to an original mopar side valve 6...........very interesting........andyd

Same here.....very interesting..........

-

10 minutes ago, Ivan_B said:

Not sure. I would probably expect a different seal for the sleeve application... But then, again, I've never even heard of these in the first place.

Uses the same seal, the sleeve is only a very few thou's thick. This is not untested tech, these things are an accepted repair. I'm running one on the crank hub of my P15.

-

1 hour ago, Ivan_B said:

What's a Speedi sleeve? A jacket you put on a worn hub to use with oversized seal?

That groove is too much. If you can see it with your eyes, the seal will not seal properly... ? The proper way to fix that is to get a new hub or machine the existing one (proper sleeve or metal coating).

Speedi-Sleeves (proprietary brand name) are a common and widely accepted repair in the automotive and commercial communities. They have been around for a long and are available to fit nearly any size sealing surface.

Your education is proceeding at a break-neck pace....first solder sleeves and now speedi-sleeves! ?

-

1

1

-

-

I think I would prefer a new SpeediSleeve over putting a new seal on a worn hub. Be sure the sleeve is secured to the hub with sealant so it can't spin on the hub.

-

9 hours ago, stukamensch said:

Hey all just joined, about to buy a 1948 special deluxe police model, it looks really clean no rust CA car, its been updated to a 12v system and a th350 trans anything i should specifically look for on these cars. Still has the original motor, and police equipment.

Thank you all in advance!

Is this car running and driving or not? Some major problem areas include brakes, fuel system, cooling system and electrical. If the car is roadworthy then it will be easy to get a rudimentary idea of the condition of these systems. If not then it is best to consider this car a project that may need extensive ($$$$) work in these areas.

It depends on what you want, a car that you can drive now or a project with good bones. It is difficult to offer specific ideas without knowing your intentions. The fact the car has a modern auto transmission is reason to wonder what other mods have been made and this makes it more difficult to evaluate. The driveshaft won't be stock and questions arise about the rear axle (brakes, final drive ratio, etc?).

-

1

1

-

-

1 hour ago, hi_volt said:

Wow, what a beautiful ride! Do you have any pictures of the engine bay and interior you could share?

https://www.barrett-jackson.com/Events/Event/Details/1948-CHRYSLER-NEW-YORKER-274271

-

2

2

-

-

10 hours ago, Doremonger said:

I just bought a 1948 New Yorker business coupe and wondering if there are build sheets available for these plus reprints of manuals? Thanks in advance.

Kissimmee or Barret Jackson? Ahhh....a closer look at the photos gives it away....found the listing.

Beautiful car!

-

5 hours ago, Doremonger said:

I just bought a 1948 New Yorker business coupe and wondering if there are build sheets available for these plus reprints of manuals? Thanks in advance.

Congrats on your new ride!

Shop manual:

-

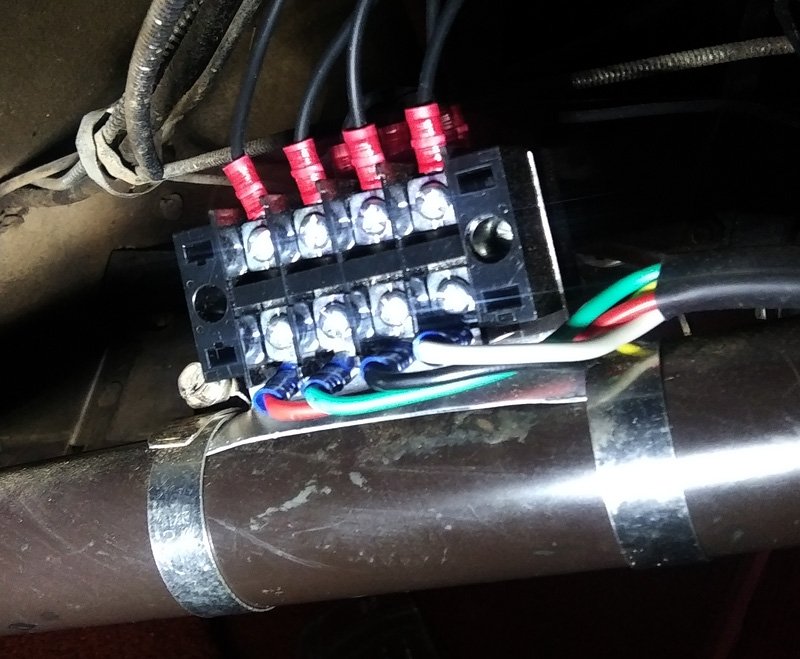

I suspect you have an aftermarket turn signal switch and it's wired incorrectly. Google Signal Stat and download a wiring diagram for the switch. It'll take some sleuthing to figure out which wires go where. Do you have colored wires like this coming out of the switch?

-

39 minutes ago, Ivan_B said:

I've had, but I know nothing about the quality of workmanship and the materials used so it is unknown what was the cause.

I would probably advise against mimicking the mass manufacturing, mainly because their main priority is cost reduction, as much as possible. Same goes with all new inventions, unfortunately. I suspect that many new techniques and materials get a bad reputation not because of their inherent qualities but because they allow greater cost reduction (poorer product quality, but still functional). If a plane goes down, now and then, its not a big deal unless a) they can be proven to be at fault b) the risk and magnitude of consequences outweigh the savings, and c) they do not have other safeguards in place, such as regularly requiring to replace all these parts anyway.

Wow………………. -

There is a very simple solution for those who have concerns or questions about solder sleeves.

Don't use them.

However....if your wiring architecture puts tensile strain on your soldered connections then the wiring design is faulty....wires too short or poorly oriented. A fundamental requirement of proper wiring design is to incorporate strain relief. Fix the underlying deficiency then any type of splice will be more than adequate in our cars. I use crimped connectors with a ratcheting crimper, never had issues even with crimps that are 25 years old in my aircraft.

I instructed mil-spec soldering during my first real job a loooong time ago where we built harnesses and boards for Army things that blew stuff up. I can still solder fairly well and don't hesitate to use it if applicable but there are far faster methods for splicing wire that are perfectly suitable for most applications.

-

Here is a comparison of those three sizes at 72 ppi:

-

1 hour ago, Ivan_B said:

These are supposed to be "heat-shrink soldering", why is there a crimper on the main banner? ?

I was under impression that these shrink (including the metal ring in the middle) but do not actually solder. If they actually solder, I would sure like to see the outer insulation jacket removed, and the soldered connection exposed for inspection, after the fact ?

You can rest assured the major brand connectors work and work well when properly applied. They have been around for a long time and are common in aviation and defense applications.

I don't know why there is a crimper in that ad. The RayChem connectors DO NOT get crimped, but they are definitely a soldered connection. The sleeves are transparent for easy inspection.

Here is the datasheet for the RayChem SolderSleeve wire splices:

-

9 minutes ago, chris 48 P15 said:

looks like heat gun is enough to solder?

Yes, they use a very low temp solder. I would source these from an electronic supply such as Digikey or Mouser to insure getting a mainstream brand instead of an offshore knockoff. (Apologies for the long link) TE Connectivity seems to be a vendor that services the aerospace and marine industry.

-

1 hour ago, Bingster said:

I have no affiliation with these folks, but ran across the ad and wondered if there is a down side to this type of electrical spice.

https://www.peachloft.com/pages/waterproof-solder-wire-connectors-gg

I've seen these used and have never heard anything adverse about them, quicker and much less technique required than for a conventional solder/shrink tubing connection.

-

That will be one cool sounding boat!

The little Suzuki on my little ZIP runabout would run and hide....... ?

-

43 minutes ago, Los_Control said:

@keithb7 has a video on how to fix that

I know how to fix the rear seal, been in there a couple of times. It still leaks......but it's just a minor irritation.

I leak a little, too.........

-

1

1

-

-

13 minutes ago, Ivan_B said:

Were these "carefully colorized" by a neural network? There are obvious mistakes\blemishes on most of these photos... ?

These cars, in their day, were brand new, so there is no surprise that they were taken everywhere across the country and abroad under all sorts of driving conditions.

Yes, the colorization is a little flakey but that wasn't the point of including the link.

Each time I address a service/repair issue on the P15 I try to resolve it to like-new condition or at least to where it will function as close to like-new as I can get it. The reason for that being my emphasis is to make the car as reliable as it would have been when it was in daily service. It has proven to be a very dependable driver (just wish the rear seal didn't leak!).

-

1

1

-

Wont shift into Reverse.

in P15-D24 Forum

Posted · Edited by Sam Buchanan

Carefully read the section in your Repair Manual on linkage adjustment and follow the procedure. If engagement has been getting progressively worse the transmission mounts may be degrading......or shot.