-

Posts

2,252 -

Joined

-

Last visited

-

Days Won

60

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Everything posted by Sam Buchanan

-

Be sure you get the air grease that is 70% nitrogen.

-

$10 a quart is a bargain......Redline is $23 per quart. But after putting up with a crunchy first to second shift until the tranny got hot, I consider the Redline to be a bargain since it totally fixed the crunchy shift. If I hadn't spent the money on Redline I would be reminding myself of my stupid thriftiness every time I heard second gear not engage smoothly. Now I congratulate myself for spending only $46 to fix this transmission! Would GL1 have worked as well? It might have....but at this point it doesn't matter. It's a matter of perspective........

-

Redline MTL provides excellent service with no gear shift crunching in my manual transmission cars ('48 Plymouth, '69 VW, '74 TR6) with no concerns about corrosion of brass syncros in these transmissions. It is a little pricey but in my opinion an excellent value due to how it keeps these old trannys happy. The modern GL oil is too slippery in the my P48 and causes crunchy shifts when cold. The diff can use the modern GL oils.

-

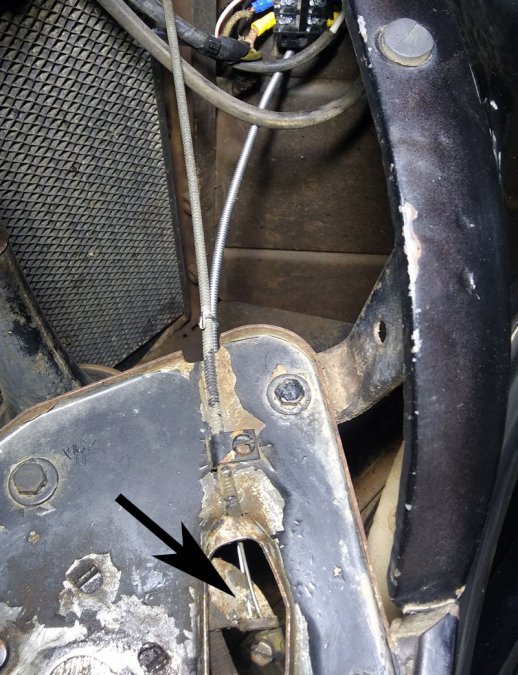

One a somewhat related note, we can have a bad day if the hood release cable breaks leaving us with no easy way to release the latch. Some have used a long bar to reach up behind the grill to bump the latch enough to free the hood but this is difficult for someone in a hurry or who has never used this trick. I attached a second cable to the latch and ran it out into the fender well so I could release the hood by reaching behind the front wheel. This is an easy mod and a broken release cable will never be a concern. I got this idea after modifying my Triumph TR6....that hood is hinged on the leading edge and a broken release cable is a BAD deal with that car!

-

https://p15-d24.com/topic/59124-rear-axle-help/#comment-635519

-

There are places where budget decisions can be justified but brakes are not one of these. Spend whatever money is needed to put your brakes in tip-top condition, your lifespan might be altered by saving a few bucks...... And to address your question...in my opinion pitting in a brake cylinder is totally unacceptable.

-

First step is to make sure the clutch linkage is adjusted properly. Proper "play" is needed in the pedal and the over-center spring must be adjusted properly. There is a template in our Downloads section for making the tool to adjust the over-center spring. If this spring is out of spec the pedal won't function properly. https://p15-d24.com/files/file/5-overspring_toolpdf/ This entry is also in the tech tips section: "Clunky Clutch For years after I got my P15 the clutch pedal would always make a loud "clunk" when you pressed it down. Clutch operation was fine, and throwout bearing free play was on the money. Adjusting the clutch overcenter spring did nothing to get rid of the noise. Finally, while replacing a master cylinder, I tore down the pedal assembly and clutch torque shaft. The balls of the torque shaft ride on spherical shaped split bronze bushings. On one side half of a bushing was missing. The clunk was the pivot ball rattling inside the remaining bushing. NAPA had replacement bushing inserts for about a buck and I was back on the road with a smooth and quiet clutch pedal."

-

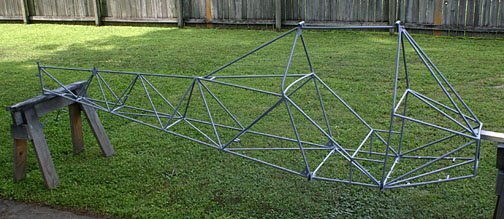

This was a Legal Eagle, a very light single-place. It was sort of an impulse build, I wanted to learn oxy-ace, gave me an excuse to build a fun little airplane. Below is the first page of the feature article I wrote about building my Eagle in KitPlanes magazine.

-

text deleted

-

I learned gas welding so I could build an aircraft fuselage. The oxy-ace is only used on 4130 steel since it's best the joints are normalized with slow cooling. I use MIG with argon on everything else.

-

The good news is the tie rod adjustments are easy to make, maybe thirty minutes if you've never done it before. The bad news is that after you see how easy it is to adjust the tie rods to center the wheel.......you will beat yourself up for driving the car for 25 years with a crooked wheel.....! ? In regard to the adjustments, if the car is driving straight now, you can center the wheel without upsetting the current alignment. Adjust each side of the car exactly one turn, then drive it to see how much improvement you made. Keep tweaking it exactly the same amount on each side until the wheel is centered and you are good to go with no strings, etc needed. Just make sure you carefully note how the threads on each tie rod run so the toe-in won't be changed.

-

MIG is pretty much the norm for body work since it is fast and fairly tolerant of less then perfect technique. About twenty years ago I purchased a small, 110v MIG with a small argon bottle and it is one of the most useful tools in the shop even though I had no previous welding experience. Body rust repair, bracket fabrication, exhaust repair--it seems to be more valuable as time goes on and I realize how much it can be used. My technique has improved especially after learning gas welding. I say all that to say this.......I highly recommend the hobbyist who is semi-serious about repair and wants to equip the shop to purchase a MIG welder. Don't bother with the gasless flux welder, the welder with an argon bottle yields far cleaner welds. You'll be surprised at how often you'll use it.

-

Hey Joe, were these on their way to needing to be replaced?? ? Yes, a linkage adjustment was needed with the new mounts......

-

-

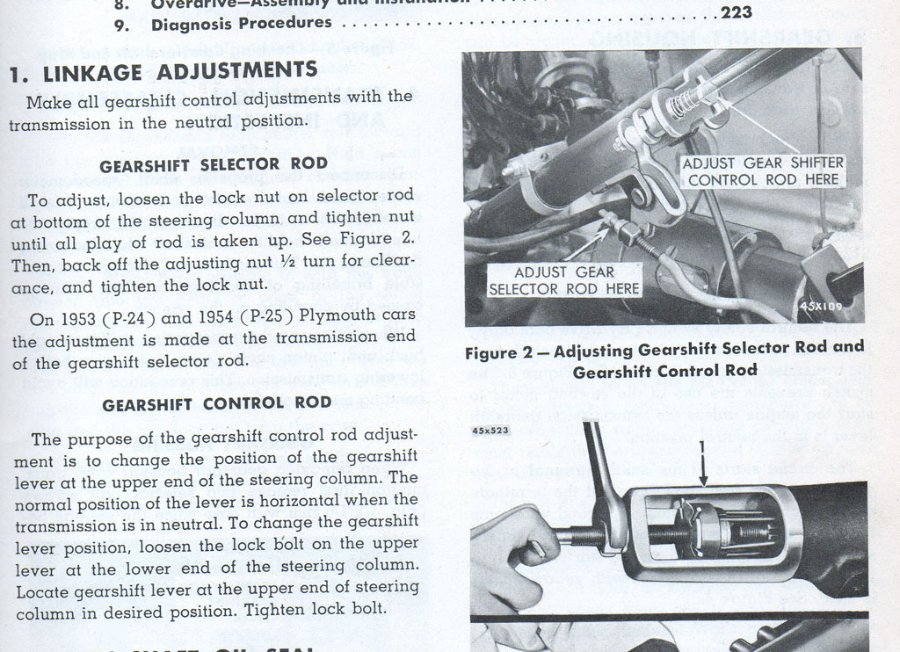

Yep, shift linkage adjustment……been there, done that. I had to make the adjustments after replacing the tranny mounts, that’s why I suspect yours have sagged.

-

Carefully read the section in your Repair Manual on linkage adjustment and follow the procedure. If engagement has been getting progressively worse the transmission mounts may be degrading......or shot.

-

Stop advancing the timing just before the engine pings while pulling that steep hill on the way to grandma's house.................

-

Your engine needs deworming!!

-

Excellent! We know what you are describing. ?

-

ANSWERED 1948 Special Deluxe police buying advice

Sam Buchanan replied to stukamensch's topic in P15-D24 Forum

Excellent. That changes the character of your original (unedited) post. Some might be concerned about whether or not non-detergent oil is in the engine, be good to find as much recent service history as possible. Enjoy your new ride! P.S. Your first purchase is one of these: https://www.rockauto.com/en/moreinfo.php?pk=10593924&cc=1486874&pt=10335&jsn=381- 42 replies

-

- 1

-

-

- special deluxe

- 1948

-

(and 1 more)

Tagged with:

-

I think you just explained why it is not practical to get the machine work you described in most instances today. Machining in a commercial shop is expensive even if you can get someone to do this small a job. You had this done some time in the past by someone who enjoyed doing this on his own time. That doesn't represent reality for most of us now. This is a similar situation to the solder sleeves we discussed recently. Both of these technologies are proven and readily accepted in a variety of applications. However, some folks are hesitant to use technology with which they aren't familiar so they are convinced it is unsatisfactory. Fine......don't use it. The rest of us will take advantage of modern tech which is usually less expensive, doesn't require old-school techniques or expertise and yields satisfactory results. Personal choice. By the way....my P15 has disc brakes, an alternator and a full-time electric fuel pump.......I don't hesitate to drive the car anytime, anywhere and it has proven to be extremely reliable. Old tech or new tech? ?

-

We discussed this extensively when I first posted this photo 3+ years ago. It isn't a fatigue crack, it is corrosion and is only on the surface. Yes, that is a worn hub and not that unusual for a bearing surface eroded by dust and a leather seal. But the Speedi-Sleeve is a good remedy. I filled the groove and "crack" with JB Weld prior to installing the sleeve.

-

ANSWERED 1948 Special Deluxe police buying advice

Sam Buchanan replied to stukamensch's topic in P15-D24 Forum

Same here.....very interesting..........- 42 replies

-

- special deluxe

- 1948

-

(and 1 more)

Tagged with:

-

Uses the same seal, the sleeve is only a very few thou's thick. This is not untested tech, these things are an accepted repair. I'm running one on the crank hub of my P15.

-

Speedi-Sleeves (proprietary brand name) are a common and widely accepted repair in the automotive and commercial communities. They have been around for a long and are available to fit nearly any size sealing surface. https://www.skf.com/us/products/industrial-seals/power-transmission-seals/wear-sleeves/skf-speedi-sleeve Your education is proceeding at a break-neck pace....first solder sleeves and now speedi-sleeves! ?