-

Posts

190 -

Joined

-

Last visited

-

Days Won

7

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Everything posted by Jomani

-

512 cid C series on Dakota chassis- build thread

Jomani replied to Radarsonwheels's topic in Mopar Flathead Truck Forum

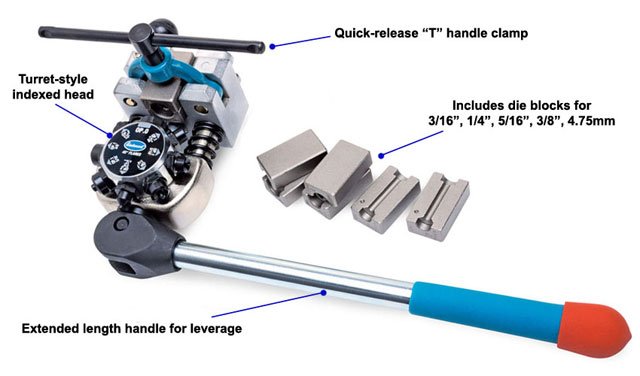

I picked this one up on sale for $120 a couple years ago when I did my old Jeep. Perfect flares every time and very easy to use. -

Got some paint on the grill today. I saw a truck a while back that had a color scheme that I really liked. I tried to pick similar colors from a book at the paint supply store in town. This is not quite what I was going for - might grow on me. I think I will go darker green - I think I’m happy with the white. The wind came up a little when I was painting the green and blew a little dirt into the paint. Overall, I think the paint came out fairly good.

-

I agree - headlights are set in on the fenders. Not familiar with the Fargo grills, but it has to be prewar. Also looks to be a 1 1/2 ton with the five lug wheels. Clean truck.

-

I had planned to get the grill in primer and set aside until I finished the frame and drive train but couldn’t resist getting it ready for paint. It has been over 30 years since I have done any real body work and paint. The grill definitely put me to the test - lots of nooks and crannies. Ready for paint. Still debating color - I picked up a couple of pints, should have the first test colors sprayed tomorrow. Going with single stage paint to keep the vintage looking finish - not sticking with original colors.

-

Finally got around to spraying some epoxy primer on the front grill. I stripped it down to bare metal back in July or August and it has been sitting on my bench since then. I have never sprayed epoxy primer before so I mixed up a small batch - just enough to spray the top piece. I was very happy with the results. Tomorrow, I will finish cleaning up the bottom section and get some primer on that. Now I am trying to decide if I should hit it with a coat of urethane primer. From what I have read, I only have about a week to cover the epoxy primer - I won’t be ready for paint for a long time.

-

The coil does not need to be grounded. The primary windings in the coil gets its ground through the distributor when the points are closed. When the points open, the magnetic field that is created by the primary windings collapses causing the secondary windings to generate a high voltage current. A ballast resistor (some vehicles use a resistor wire) is used in some vehicles to lower the voltage to the primary side of the coil after the engine starts. Typically, the full battery voltage is used during cranking, then a lower voltage is used once the engine is running. The lower voltage helps to keep the coil cooler and reduces the likelihood of burning the rest of the ignition components.

-

I appreciate the advice. I like the idea of making the height adjustable. At some point, I need to pull the cab back off and add some reinforcement - I want to be able to roll it onto my trailer when I get to the point of painting. The casters I used will lock in four different directions. I set each wheel facing a different direction and it holds very well.

-

Sounds like keeping it original is the way to go. If you have stuck rings, which it sounds like may be the case, the fix can be very inexpensive. Pull the head and oil pan, remove the ridge from the top of the cylinder, and pop out the pistons. Soak the pistons, free up the rings, and clean up any excess carbon, and put them back in. A couple hour job, but it does typically require two people. Running the engine to see if it will improve can be risky. The number two cylinder is most likely not firing. You risk washing the cylinder with unburned gas, scoring the cylinder, burning the piston, etc. If the rings are still stuck after getting it up to operating temperature, putting a load on it will force them to expand one way or the other - my experience has been that they break, or worse break the ring lands on the pistons. Hopefully all goes well.

-

Did you try shooting some oil into the cylinders? If the numbers come up with oil, it is most likely rings. If the numbers don’t change, it most likely indicates a burnt valve or piston damage. Do you have a lot of crankcase pressure? If it were mine, I would pull the head to see what is going on. Head gaskets are relatively inexpensive and you will learn a lot about your engine in a short amount of time.

-

I need to be able to move the cab every time I want to work on it - I wish I could set it on jack stands and leave it in one place. The old motor home I dismantled had a heavy duty rack on it that I cut up. I had some heavy duty casters from another project that I disn’t use. A days worth of fabrication and I can now move the cab anywhere by myself. The last picture shows it tucked away under the car port.

-

I spent the last couple days pulling the bed and cab off the truck. The wood on the bed has seen better days - decided to cut the bed up to make storage easier until I reach the point in that point in the build. I plan to use the steel that I salvaged from the old motor home (lumber rack and home made bumper that you can see in the first picture) to fabricate a rolling stand for the cab. I don’t have a shop so it will move in and out of the garage a lot over the next six months or so.

-

Love the wood. That is the look I want to achieve on my 47 - I am a long way from that point. It is good to see that you are still making progress. Before you know it you will be cruising down the road...

-

Looking good. The nice thing about stainless trim as opposed to chrome is that you have the same material through the whole piece and not just a plating. Filing, grinding, sanding, and polishing can smooth out all of the small dings and remove any discoloration. Below is my favorite video - he does a great job explaining the process.

-

Be sure to share pics of the stainless trim when you get it straight. When I straightened mine, I found that I had better luck using hardwood as the dolly - less chance of stretching the stainless. Do you plan to polish it out or just going for straight? I found out the hard way that you can’t skip any steps in sandpaper. I ended up starting with 100 grit paper and progressing through 2000 grit (wet/dry when available) without skipping any steps, then three different polishing compounds. Lots of time but worth it in the end.

-

Thanks

-

Parts for the engine came in so I couldn’t resist getting started on the rebuild. I got the block cleaned up, new Competition cam and crank installed and pistons in the holes. Very happy with the progress so far. I should have the heads back together tomorrow - cam kit came with new valve springs, caps and keepers. I need to check the spring height on each valve so assembly will be slow.

-

The orange paint came out ok. After a couple days drying, I can give the final buff and clean up some of the lines.

-

The flathead now in storage.

-

Ok back on track with the build. I set the trim aside while I checked out the engine - got back on finishing the front trim today. I found enough of the original trim color to match the paint. Masked off the trim, scuffed up the surface and hit it with a self etching primer.

-

I will contact him and get back to you

-

Unfortunately, I didn’t get the shift lever - didn’t figure I would need it for my build.

-

Sometimes they don’t respond because they included the wrong contact information in the listing. A while back I bought an engine on CL for my Jeep. The listing had a phone number that went directly to voicemail - after I left a half dozen messages, I finally got a call back from a lady who was upset that people kept calling her - turns out the guy transposed a couple of numbers. Hell bent on getting that engine, I took his pictures and verbiage and posted as “wanted”. I got a call from the guy, rather indignant that I “stole” his pictures. After I explained, he admitted that he was surprised that he hadn’t gotten any replies to his ad. He gave me a good deal on the engine...

-

Looks like I committed to converting to the 360 (still on the fence about the automatic). I got a couple of estimates to fix the Flathead block - $800 to fix the two cracks (bore, pin and sleeve) and $1200 if I went ahead and freshened up the valve train while it was in the shop. It has been a long time since I needed machining services - sticker shock to say the least. I tore down the 360 over the weekend expecting to find a tired engine with 120,000 miles on it. Instead, I was pleasantly surprised to find a freshly rebuilt, .020 over diamond in the rough. When I bought the old motor home, the guy claimed the engine only had a couple thousand miles on it. He said he picked it up after it had been sitting for “many” years. Given the difficulty of pulling an engine out of a 1974 C Class Motor Home, I had zero confidence in his claim. I can honestly say that I have never seen such a nice engine on teardown. New crank, rods, pistons (the crosshatch is still visible in the cylinders). The cam looks good but will get a new Competition RV cam. Heads look new - if not new, someone did a fantastic job making them look new. Years of sitting did take a toll on the cylinders. There was some minor surface rust in a couple of cylinders. A quick once over with a stone hone removed almost all of the pitting. I will finish with a flexible ball hone to get a perfect crosshatch, new rings and bearings and slap it back together. I put the flathead in the corner and ordered all of the new parts for the 360. It looks like the guys over on the Power Wagon site have motor mount kits and steering conversion kits that may work on the WD series trucks. Looking into that this week while I wait for parts to arrive. Not sure this build meets the requirements for this site anymore since the flathead is out - I am sure you guys will let me know...

-

No. This is the second engine I purchased. The one that came with the truck was a 218. I ended up selling it since the original trans was bad and the engine smaller than the original 230 - was planning to convert to the 360 and auto trans. I stumbled on this engine and 4 speed trans so I decided to go back with the Flathead. Now I am undecided about the direction the build will go.

-

Too bad you are way across the country. Just found out that my engine is junk - very likely that I will not be using the bell housing, flywheel, clutch, and transmission that I just picked up for my WD-21. I plan to pull the top off the trans tomorrow to see what it looks like. Hopefully, it turns out better than the engine.