-

Posts

917 -

Joined

-

Last visited

-

Days Won

13

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Classifieds

Everything posted by bamfordsgarage

-

Fair enough James, and I stand corrected. My ‘get r done’ method would, I am pretty sure, get those shoes in the drum and the brakes working but would not be optimum and by the book. I am puzzled however by your statement that the shoes should be a “perfect match” to the drums… no arcing for a bit of clearance at each end? Also, if Marc’s drums have any amount of wear, I reckon a few thou longer pin length will not matter. IMO. Not trying to argumentative… just trying to offer practical suggestions. I rarely work on stuff this new, so perhaps my standards are too casual ?.

-

Marc, IMO you need to heed Andyd and Allbiz… This is not complicated. Factory spec is for 3/16 lining. Your shoes were relined with 1/4” material. Your lining was 1/16” too thick. 1/16” is 0.0625”, roughly 60 thou. You had 30 thou removed last week, get another 30 thou ground off and you’re ready to go. Your pins look close enough to the same length… a few thou shouldn’t make any difference.

-

ANSWERED Is the Mopar pro brake tool any good?

bamfordsgarage replied to FarmerJon's topic in P15-D24 Forum

Inspired by Sam B's creation, I made this version last year and it seems to do the trick. The pair of nuts proved helpful; a lone nut had enough clearance at the threads that the tip would wobble unacceptably at the shoe surface. The two nuts are only joined by the welding at the bar and they are slightly mis-aligned. This takes up the thread play and the tool tip remains stable. Speaking of stability, I originally had just the one flat bar between the spindle nut and shoe gauge — that, too, was a recipe for floppiness. Triangulating the assembly with a second flat bar did the trick Thanks, Sam! -

Running board rubber replacement 1935 PJ

bamfordsgarage replied to rrunnertexas's topic in P15-D24 Forum

My experience with trim adhesive is that some types never fully dry (similar to contact cement) and thus edges can lift over time if the material is so inclined. If it were me I would use a premium construction adhesive or Right Stuff gasket maker. This last stuff, in my experience, is like miracle in a tube. I’ve used it to glue all kinds of materials together and even ‘repair’ cracked water jackets — repairs that last for years. -

So, I've measured the ring land depth at 0.168" +/- and the ring hight as 1/4". Unfortunately, I have no P15 rings handy to check thickness and depth, and I was unable to find anything further on this site. Would anyone have the specs on these, or perhaps a few on the shelf they could quickly measure? Thanks in advance.

-

Yes and no: similar variable friction drive to the CarterCar and Metz for example, but moving the driven (spoked) wheel toward the perimeter of the drive (fly) wheel increases road speed, albeit with a reduction of torque (never plentiful at the best of times with this rig). Conversely, shifting the driven wheel toward the centre of the drive wheel reduces road speed but increases torque, just what's needed for hills and starting-from-stop. Moving the driven wheel past centre puts the transmission into reverse. I also use this position as the primary brake... there is only one dinky little band brake drum (like a P15 handbrake but much lighter) connected to the foot brake pedal.

-

Thanks for the replies… I missed the ring groove depth earlier, but have just measured it at 0.168” +/- 001”for all three rings.

-

I'm working on my 1906 Orient Buckboard, a single-cylinder horseless carriage with a 3.25" bore and4-1/2" stroke, basically the same as a P15 or my Canadian D25. Compression is poor and the rings could use replacement... would P15 rings work in this application? The bore is correct although ring height could be different. See attached photos for dimensions and photos. All comments and suggestions welcome.

-

It’s been years since I had the starter out of my D25, but could you carefully jam something in that hole to catch the ring gear and keep the flywheel from turning? Given the large radius of the flywheel, stress on the ring gear teeth would (should?) be moderate.

-

Thanks Sniper, much appreciated. I snagged the last four of this tire in stock, with Fed-Ex ground to western Canada for just over US$50. There were, as you suggested, several options including a summer-tread Coker for $168 each but I like the more aggressive tread of the Kelseys — my heap sees a lot of gravel and occasional mud. I'll likely leave them on next fall and see how they handle snow. Screen shot below shows "Not in stock" 'cause the four they had are now MINE! Bonus: I was having trouble locating replacement tires for my '26 Ford T and Summit had a bunch of Firestone 440/450-21s with a reasonably aggressive tread (gravel, mud and snow service again). Four less tires on that shelf now too. Credit card is still smoking...

-

I’ve been running bias tube-type tires without tubes for years… 11 years on the summer set and nine winters now on the winter studded knobbies. Stock original rims for both. Many thousand miles on each set, with the only problems being a handful of bead leaks, all corrected with a bit of bead sealer and remounting. Point of interest… I tried to order a set of 600x16 summer tires last week and my preferred supplier Lucas in Long Beach CA advised they have no stock and the manufacturer has a backlog of 40,000 units (multiple sizes of course).

-

My perspective and experience from 30 years driving a mechanically stock 1947 D25, the sister car to yours: — The 6-volt +ve ground system worked just fine back in the day and still will if properly maintained. — 12-volt conversions have their place for various reasons, but if done just to help the car "start better" they are an expensive bandaid. — Really slow cranking "rem......rem........rem..." sounds like a weak battery and/or dirty connections. Poor battery cable connections cause a lot more trouble with 6-volts than 12-vts (but cleaning them up costs a lot less than a 12-volt battery and all new bulbs) — I'm negligent when it comes to regular tune-ups (it's been several years and thousands of miles) but my D25 starts reasonably quickly at -15°C/5°F without being plugged in.

-

Are you having problems with your current setup?

-

I recently rebuilt the roof rack on my '47 D25 and treated the car to a new set of presents. The old heap is rarely garaged, and whenever I've put a load up there for Christmas a few go missing overnight. No big surprise. No big loss either — the boxes and bags are weighted down with rubbish (this year it's demolition debris from a nearby infill project) and this whole load cost less than $20 to put together. The wrapping 'paper' is actually dollar store plastic tablecloths and the bows are taped securely to withstand highway speeds. Which, for me, is about 50 mph. As I'm always one to climb onto the latest bandwagon, this Christmas the old heap is a gas-electric hybrid... the dollar store Santa mascot is powered by a photo-voltaic panel and dances merrily away, dawn to dusk, even on cloudy days.

- 5 replies

-

- 10

-

-

-

-

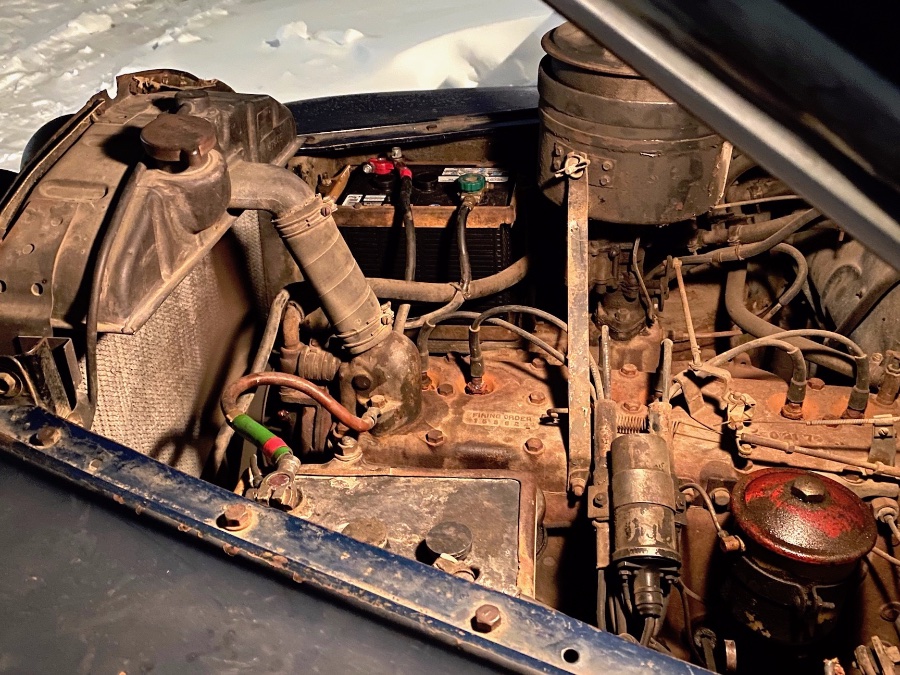

I chose not to have my D25 block hot-tanked as I wanted to preserve the aged appearance. A couple bucks down at the coin wash (wash wand seen at top-left) flushed out a lot of debris and I've had no cooling issues since the rebuild. The brass water distribution tube was removed prior to the flushing.

-

I recently rebuilt the roof rack on my '47 D25, which with mission creep, entailed going through not only the rack lighting (signal, marker and hit brake light), but replacing the long-dead second battery and cleaning up various connections throughout the charging and lighting circuits. The generator got new brushes a few years ago; the regulator was set up by an independent auto electric shop around the same time. All is functioning well now, and some readers might be interested in the real-world performance of this factory charging system... Photos were taken yesterday evening, with the following electrical loads: — headlamps on high beams (H6006 halogen 6-volt) — two heater fans on full (the factory heater and a second, identical, heater installed 10 years ago prior to an Arctic road trip) — four marker lights (front greens are visible, red rears were obstructed) The ammeter showed discharge at idle of course, but reached 'cross-over" at about 1,00 rpm and positive charge at higher speeds. I find this very satisfactory — even with the additional non-factory loads the generator keeps up at 20 mph or faster. No inclination here for an alternator or 12-volt system (no 12-volt loads either!) The second battery was installed 11 years ago in parallel with the factory battery as a reserve for camping and longer road trips. It can be isolated as needed.

-

I second Robert's comments... it was a real fun old car day! Up here in Edmonton, most northerly big city in Canada, we are not 'on the way' to many places and get few visitors. It's always fun when someone drops by and I can tell you Robert makes very good company. Here are a few more photos: Robert piloting the Mighty D25; a later-'30s Packard sedan; Pierce-Arrow sedan with signature headlights-in-fenders; more '30s sedans including a Packard with possible sealed-beam conversion; general yard view. Astute readers will note the sky clouded over since Robert's photos posted above — in fact, my yard photos are about a year old and were shot whilst retrieving the replacement steering box that is in the car now.

-

Here is most of what we packed for the 2,400 mile run up to Tuktoyaktuk, Northwest Territories, on the shore of the Beaufort Sea and as far north as one can drive in Canada's Arctic. As it happened, our only troubles were a bad fuse (internally-open) and worn out generator brushes. We had fuses of course and I was thankful I threw the parts car generator in the trunk just in case.

-

Thirty-five states, three provinces, Atlantic Ocean, Pacific Ocean, Gulf of Mexico, Beaufort Sea, Pikes Peak, interstates, blue roads, dirt roads, no roads, deserts, -35F, 95F, heavy traffic, no traffic, whatever… Stock brakes, stock suspension, stock rear end, 6-volts +ve ground and original engine. Definitely not for everyone but it can be done — and it sure works for me ?

-

Well, that was a ton o' fun! Here are a few pictures. Video has been promised and I'll post more in due course. The most enthusiastic demographic wes white-haired women. No damage, no injuries, no attention from the authorities, tons of smiles, waves and Huh???s

-

-

Thank you Wagoneer. All worth considering. 1. Agree 2. I'm confident the two 1000 lb-rated straps combined with cleats (photo 2 above) will keep it in place. 3. Maybe. Goggles and ear protection for sure. 4. That would be a sensible choice. 5. Oh, you'll see pictures! _ _ _ _ _ _ _ _ _ _ _ Tomorrow we build.

-

I did give thought to a swivel, however that required more engineering than I have time and inclination for. The speeds will be modest (we are talking Model Ts here) and this chair will support someone kneeling and facing backward. Another requirement is that we will only use materials on hand, spend $0.00 out of pocket, and it should look like somebody dreamed it up in the ‘50s. . Hence my Great-Aunt Lilly’s chair, and hardwood boards that were probably stockpiled 50 years ago by my Dad. Sadly, the bright red tie-downs give it away. No helmet. Chair will be strapped down as will the occupant. Most of the time ?.

-

The Foothills Model T Ford Club (Calgary AB) is celebrating their 50th anniversary with a three day tour out of Rocky Mountain House, AB this week. Wednesday is a big drive to Ram Falls... lots of gravel roads, hills and fantastic scenery. My D25 will be the camera car for the Ram Falls outing. Idea at 7:00 last night, followed by conceptual mockup with existing materials. Cutting and fitting today, finish it up tomorrow. Seat anchors could be beefed up a tad. Yee-Hawww!

-

FWIW, the top photo in Tom’s original post was mine, labels indicate how the relay was wired when I purchased my D25 some 30 years ago. Horns worked fine for decades but a wiring fault elsewhere eventually caused trouble.