Leaderboard

Popular Content

Showing content with the highest reputation since 04/16/2024 in all areas

-

8 points

-

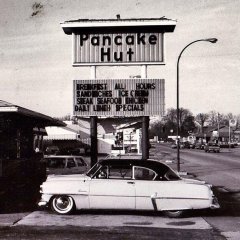

My Great Grandfather, and guessing my Great Grandmother with the '55 Dodge (I'll be inheriting this summer) and what I believe is a '55 DeSoto. The truck was my Great Grandfather's then my Uncle's, and then my Parent's, and soon to be mine. My Dad just told me that he is getting too old to work on too many toys, and he is giving it to me. It is in a little worse shape than here, but pretty much original. I'll post pictures of it's current state, in the correct area, when I get it out of the barn, but from what I recall it definitely will need a gas tank and fuel pump, amongst other things.6 points

-

The filter is far from the headers. The pipe that it is close to is an intake runner, and when the engine is running those runners stay very cold. That's why I built it like that. Cold air is denser and allows more power to be made. The long runners introduce a ram effect on the intake charge and produce more power. This was a question about installing the windshield and rear window.2 points

-

I like aluminum paint, it dries without any buildup. Check the inside of the tires for any tags, that could eventually rub a pin hole in the tube. I wiped the inside of the tires and the tubes with corn starch with a cloth. It doesn’t need a lot. I paint the bead of tire with rubber lube, so the bead slides easily on the wheel as it sets, you can put the lube on the wheel seat to ensure a soft seating of the bead. The flap doesn’t need any lube. Set the opening of the lock ring opposite the valve stem. I have a special hammer/mallet with a duck bill on the other side. I use the rubber part to tap the lock ring into place as I fill the tire slowly by adjusting the pressure on my regulator. This assumes that your rings are clean and no cracks, they have been painted and the notch in the wheel where they lock is perfectly clean. I’ve trashed wheels and rings that had been beaten with metal hammers. The lock ring ends should be almost touching when done correctly. Any questions, ask, it is a risky job even if you’ve done it before. These are 16” wheels, but the same design as the 20” wheels that I have. Once the bead is set and the lock ring is secured properly, I let the air out and refill with the valve core installed to eliminate any tube wrinkles. After you get it to pressure, you can bend the valve stem for access when the wheels are on the truck. If there is anything you don’t understand, ask. Rick D.2 points

-

Another vote for making your own. It’s like a puzzle to solve. You screw a few up. You learn. You get better. Building and shaping your first ever 3 ft line across the left rear axle housing? Order two 25 ft rolls of 3/16” brake line tube. 😄2 points

-

preformed and then curve and bent to fit a box for shipping, you better off making your own tailor fit set.......2 points

-

Here's a possibility. I wonder if the Dodge rod bolts have threads that are cut, while the Pontiac rod bolts have rolled threads. Rolled threads are formed by dies that displace (smash) the material into the shape of threads, without removing any material. This results in threads that have larger outside diameter than the adjacent shank section of the bolt. On the other hand, cut threads are just that - they are made by cutting material away to achieve the thread shape, so the threaded section diameter will not be any larger than the diameter of the adjacent shank. It's kind of hard to tell from your photo, but it looks like that might be the situation. If so, then accordingly, the Dodge rod might be made with smaller bolt holes to snugly fit its cut-thread bolts, but the Pontiac bolts, with their rolled threads are too large to fit. I have a couple of Dodge 230 flathead rods at home, along with their bolts, and I can tell you that the threads in those bolts have the appearance of being cut, which surprised me, since I have seen other Dodge flatheads that have the appearance of having rolled threads. I have no reason to think that those are not the original bolts, and perhaps they were early rods that used cut-thread bolts. I could take some measurements and photos of those rods and bolts some time in the next few days and we can see if they match the dimensions of your bolts. We can also see how thin my other rods are (the ones that used rolled-thread bolts) in the wall between the bolt holes and the bearing saddles. I remember them being pretty thin. We might find that you have room to ream out the bolt holes in your rods to accommodate the slightly larger Pontiac bolts, or some aftermarket bolts, such as those from ARP. From the strength and durability (fatigue) standpoint, the bolts containing rolled threads are very much preferred. I believe virtually every manufacturer uses those types of rod bolts nowadays and have for many, many decades. I remember seeing early rod bolts from other engine makes that used cut-thread bolts, but I think most everyone moved away from that type of design long ago.2 points

-

with all due respect, items needed to exact this repair is common at any hardware store or big box building supply, TSC etc that one can walk in, get the item, pay and immediately got to work repairing. While mail order from many companies and sites are MOST BENEFICAL when you dealing/needing bulk quantity, I have to state IN MY OPINION this is not the best option for this particular thread. Heck if it boils right down to it, one can find where a person may park a chevy/gm product and find where these have fallen off and free for picking up. Ok so the last part is a joke...maybe real at times, but still intended as a jab/joke.2 points

-

SURVIVOR: saw this Dodge between Lake Graham and Newcastle2 points

-

By turning the ignition on and then off you did the same thing the points do when opening and closing, letting the coil fire a plug, and if a gas mixture is in that cylinder when it fires it'll rock the engine. That's my guess.2 points

-

Likely not a "factory" accesory, more likely a mass produced catalog or dealer option, these aren't listed in the Accesories section of the manuals.2 points

-

That's great news! No need to PM, you can just post them here, I am sure everyone would appreciate these, for reference 😀1 point

-

I suspect that engine noises are best troubleshot from under the hood/underneath the car. Have someone step on the gas and listen 😉1 point

-

1 point

-

Stainless, when in contact with ferrous will rust. I have done a lot of stainless projects over the years and you have to avoid contact with ferrous at all costs, especially on sanitary work. Cupronickel tubing works well. It does not rust and it is easy to form. The best SS to use would be 304L or 316L but hang onto your wallet and plan on purchasing some rather expensive tools to form the flares. If you do not have plans to show your car at Amelia Island or Pebble Beach, save some money and use the copper nickel alloy tubing.1 point

-

Stainless steel is more brittle and work hardens easier and it does rust. Not better on many fronts.1 point

-

There is no rational reason for having a plastic filter in proximity to the exhaust manifold. I don't even like having a metal filter in that location because it can absorb heat which is transferred to the fuel (vapor lock). There are locations that are much better suited for a filter.1 point

-

I recently replaced the windshield in the '69 Beetle. A bottle of KY Lube from the local drug store turned out to be a superb windshield molding lube. It also triggered several off-topic comments from bystanders......1 point

-

Are your rims actually rusty on the inside? Mine were pretty clean (original paint, too), so I just washed them and that's it. The tubeless tires use soapy water for mounting. Since we have tubes, I just used the good old tire talc powder. Both on the tube and inside the tire (spread it around with a piece of cloth, etc). Do not use organic baby powder for automotive tires 🤣 You don't have to worry about setting the bead, etc. Your biggest concern should be how to not pinch the tube in between the tire and the rim. Also, make sure that you have the correct-size tubes. One of my old tubes had a fold in it. When I put the tires on, I inflated them to around 10 psi, just to hold shape, and then pushed around the sidewall, on both sides, to make sure that the tube was nicely seated in the middle of the rim.1 point

-

1 point

-

1 point

-

I've heard a rumor that flathead replacement fuel pumps have a half-baked machined pin installed 🤔1 point

-

It’s good to learn with these old bombs. When you get that perfect double flare you’ll then realize that you forgot to put the nut on. Oops . I enjoy making up my own fuel and brake lines. I agree with Plymouthy Adam’s, you’ll have to reshape them anyway after unpacking them.1 point

-

That is a very reasonable answer. I have some smallblock dodge ARP rod bolts and just like the pontiac bolts, they also will not go into the 218 holes. I would appreciate your efforts in measuring your flathead rod bolts to compare numbers when you get the time. Thank you and anyone else who has early flathead dodge rods available to measure the rod bolts. This seems like a plausible answer. WELL AS A MATTER OF FACT: You are the man of the hour. I just went out to the garage with my nut/bolt gauge and also a 3/8-24 standard bolt with nut and amazingly so, they fit the Dodge rod hole, rod bolt, and nut exactly. Additionally, the pontiac and ARP bolt will not thread onto the nut/bolt gauge or the 3/8-24 bolt and nut. We have a winner!! Sorry, no chicken dinner. But many thanks for the solution. I never would have thought in that direction. Now it's a matter of if the rod and cap will take a reaming without interfering with the bearing. Thanks again for all the responses and especially the solution. It does seem odd that in all the builds online, no one mentions this. Thanks again all. dan...1 point

-

I would check how far away they move the shock from the frame. i do like that mounting surface. I been thinking about my 1948 Desoto.1 point

-

The engine pictures are current, but it's not done under the hood. Planning on using a fuel block and hard lines. I set that up before I was able to find the right fittings to use on the hard lines. The filter is in a temporary position. As an update, I have been able to put some of the stainless on the strips that are on the glass. Slow going and hard on the hands.1 point

-

The drag links I'm familiar with had one end with cotter pin and slot cut into the end that a wide screwdriver blade or drag link socket fit into for adjusting and the other end would be a tie rod style. If the end that has play is similar to the tie rod style Sniper put up, replacement is your needed. If the other style, I believe some replacement sockets and cup, spring may be available. Post a pic of the bad end if you can.1 point

-

1 point

-

I agree with you that could happen, but only because it is a Pertronix. Points system won't do that because they fire on points opening. With the points open at rest there is no current flowing so it won't fire. Closed at rest there is current but the closed points don't interrupt the flow so spark. I have read that Pertronix fires on point closing, but have no personal experience with them.1 point

-

Interesting question.......those mount on a flat surface which may or may not work where the chassis upper shock spot is on the 1940-48 mopars, also the lower mopar mount is basically pointing to the rear of the car....these mounts when attached to the chassis have the "pin" pointing more or less at 90 degrees to the frame........but usually the upper & lower shock eyes can be turned at 90 degrees to each other...........I'm curious whether they may work.........andyd1 point

-

1 point

-

SURVIVOR: saw this Dodge between Lake Graham and Newcastle1 point

-

I have only installed a 2 piece flat windshield once, so I cant give specific advice, but I recall that multiple friends are a big asset to the task. Some pizza, cigars, beer, whatever you have to do to get some extra hands will be well worth it. Go slow and be patient, you can make it happen. Good luck!1 point

-

I consider points a switc0h. Open, close, on, off. Ignition switch on, ign switch off. Logic tells me my previous post is a possible scenario and every electrical circuit in the truck is available when the key is on.. I don't know whether or not Pertronix would or could respond similarly. How repeatable is this condition? Now that it's sat for a while will it do it before starting the engine or does it have to be run for a while. Will it do it after sitting for ten minutes or a half hour? Will it do it a second time, turning the key on and off immediately after it does it?1 point

-

I went to Tractor Supply this past weekend, for the second time in my life. That is all, carry on ship's work.1 point

-

1 point

-

Never saw the points firing a plug when turning the key 🙄 Is this a stock setup, besides the ignition? Are you running an electric fuel pump or any other things connected to the ignition switch?1 point

-

and as such when it is no longer original (as in not broken on assembly) toss these for some fresh hardware preferably stainless steel, BUT if you are a purist, and must stay with the stock stuff break out the molasses and let the big dog eat, weld the breaks, chase the threads and when completed apply for social security......enjoy a few pancakes while soaking your nuts and other hardware1 point

-

well, .008 is within factory specs..just at the upper end..you can ride as is..and monitor this and address should it change...or go the added step to reduce this now while you are working this issue. The problem with many values and ideas expressed here is they do not reflect the values and standards of the engineers and it was well known, Chrysler aligned the company with the best engineers out there. Some folks just like to yell out, close enough and throw in the towel as it may be labor intensive.1 point

-

So in 2005 I bought 4 uniroyal 205 75 r15 radials from Walmart,at 52 bucks with mounting balancing and unlimited road hazard warranty, mounted on new 15 inch aftermarket rims,if memory serves I ran them for 2 years. They were a bit short in diameter compared to the 6.00x16 original size. In 2007 we decided to drive to Charlotte, NC to attend the POC event there. In preparation for the trip I mounted a pair of 225 75r15 on the rear to drop some rpms going down the road. I put the 205 take offs in a black contractors trash bag and stored them under my work bench in the garage. Three years ago, I replaced the fronts with the stored pair. After about 45000 miles the fronts showed equal wear, at about half tread depth, no scalloping and no visible checking or bulging. The reserved set still looked new with 80 % tread and no visible faults. They have about 9000 miles on them since re mounting. The rears now have about 60k on them. They show as good condition with about 1/2 tread left. They came from Pep Boys and are what was then their Cornell house brand, according to the paper work their out the door price was 115 for the pair. Looking back, my father would be proud of my parsemoney in this matter. Others would call me a cheap SOB. Whatever, I think, I will let them ride for the season. Looking on line, both the 205 75 and 225 75 sizes have been relegated to trailer sizes through tegular retail sources, so not good news. I loath the thought of dealing with Cocker...1 point

-

For the speedo pinion seal, I found a Honda #91204-HB3-004, is a perfect fit.1 point

-

Pro tip. If you have a bunch of transmissions and go hunting through them for the proper gear to match the 3.73 you swapped into your coupe make sure you reinstall all the wrong ones correctly. Otherwise later on when Dad goes to install one of those in place of the OD he's not selling with the 50 Plymouth bad things will happen to the new owner. Like the tail housing exploding....1 point

-

1 point

-

1 point

-

The decline of the Champion Spark Plug and the death of a company. The Champion electrode was made from mainly tungsten powder at a company called Fansteel in North Chicago. They mixed, pressed, sintered, burnished and then brazed it to the copper sparkplug core before shipping them out to Champion for assembly. The company also made many other items like the Lynx golf club casting, High end tungsten darts (Black Widows & Diamond Backs) as well as supporting WW1 & WW2 military needs, they downsized in the late 80s and were dismantled early in the 90s along with VR Wesson a sister company that made carbide cutting tools. Fansteel Inc.docx1 point

-

1 point

-

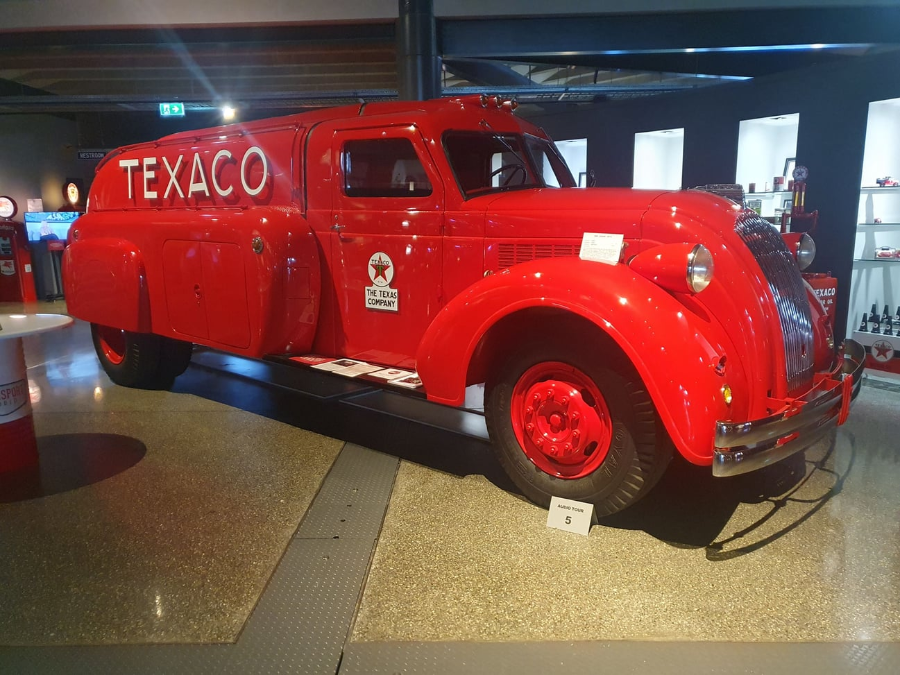

That is a great calf hauler! love the scenery…… cool find1 point

-

SURVIVOR: spotted this '52 in Jacksboro...it's had some work done but this was the only time I saw it at the old fillin station that I've motored past several times in the last 6 months1 point

-

So I am watching Roadkill and they are in Darlington. In the museum, Freiburger points out his favorite exhibit, the winner of the first 500 mile race. A 1950 Plymouth.1 point

-

Your P15 must have the up to 1948 bell housing with the four round hole vents. This 1942-1948 housing has two drilled 5/16" X 18 tpi threaded holes to mount the clutch torque shaft pivot bracket. 1949 and later bell housings with the top big rectangular vent don't have those two left side drilled/tapped holes. This is because the pivot shaft bracket is mounted to the underside of the bell housing via a plate bracket on the 1949 and later Plymouth bell housings. I think Hollander and the parts books are wrong on saying all 1942 thru 53 housings are interchangable. You can use a 1942-48 "early style" bell housing on 1949 and up Plymouths but you cannot use a 1949 and later bell housing on a 1942 thru 48 plymouth.1 point