Leaderboard

Popular Content

Showing content with the highest reputation on 04/05/2019 in all areas

-

4 points

-

i just found this battery cell tester at a local antique shop. It is a Hoyt model 638. i can't find much about it online, but I suspect it was made in the 1960's. I will probably never use it because modern batteries do not have exposed bus bars, but it is a welcome addition to my collection of garage oddities. I already have several other old cell testers.2 points

-

The two roundish pieces go on each heater box. The Y goes at the back of the head and splits the coolant to each heater core and also always the water to be turned on and off. Here is my heater cores mid resto and you can see the 3 stand offs where those roundish pieces mount.2 points

-

2 points

-

Yeah, I think the load "dwarfs" the trailer... it is actually a 14k. tongue weight, photo must be deceiving, hardly touched the overloads. anyway, he is at home, we are in Gold beach, caught a glimpse of the gray whales migrating..... like Kenny Rogers said " got to know when to fold them" ?2 points

-

2 points

-

Overall appearance of inner plug area says loudly, Water. The hood center strips leak right over the spark plugs! leaking plug gaskets contribute. DJ1 point

-

I found the easiest solution for this old problem. Since you need either a new front bearing retainer of the right size or a car throw out arm which is probably just as hard to find, I had something fabbed up instead. My machinist made me a nice press in oilite bushing for the throw out bearing. Those should work just fine and might help somebody else down the road.1 point

-

1 point

-

If someone doesn't beat me to it - I'll snap a quick picture of the parts book for this. I would highly encourage you to put this on your list of things to acquire for the car.1 point

-

The first Q'ers are arriving....the overnighters as it were....let the party begin!! 48D1 point

-

My '54 Suburban had some purchased floor panels for the upper floor below the dash. The metal is very thin, would take a very good welder. I made cardboard panels for the floor panels front, to where the passengers' feet rest. I took those panels to a local sheet metal shop and had them duplicated in 18 gauge metal. I removed all from front to rear, then I used one piece on each side of the drive shaft hump. I have help help this Saturday for installation. That is the last big item just cosmetic items after that.1 point

-

1 point

-

As Andydodge says, the horn button or horn ring is used to ground, or earth, the horn circuit. It seems that with a pushbutton, the wire to be grounded would have a contact at the end of the steering shaft, and the pushbutton would push a grounded contact down against the horn wire contact. A spring would keep the contacts apart. My horn ring doesn't work that way. For my steering wheel, with a horn ring, the horn wire to be grounded extends to a round gizmo that pushes down a large spring, which grounds itself against the metal steering wheel hub. The legs of the gizmo are screwed to the steering wheel without being grounded. Without intervention, the spring contacts the gizmo, and the horn would sound. Push the spring away from the gizmo, and no horn. So the horn ring works full time to push the spring away from the gizmo. The horn ring is insulated from ground, and has lugs which push the spring away from the gizmo. Tilt the horn ring, and part of the sping can make contact with the gizmo, grounding the horn circuit. (Or try touching a grounded wire to the horn ring. The horn should honk.)1 point

-

Radarsonwheels Hopefully you marked on the headers before taking it apart- the location of that area needing clearance. Instead of just a hammer (ballpean), use a socket and hit it to make the clearance needed. Much cleaner appearance! ? Just my OP. DJ1 point

-

I actually think, but admit I was never paid to think. Beating or "massaging" the headers, was a acceptable way .... way back when Radarsonwheels was in diapers. I personally do not want to say if it was acceptable when I was a kid, would be a hint to age. Myself, I will stand by and hand the correct size hammer for the job.1 point

-

Works great! Just beware that oil based paints can only be top coated with another oil based paint, which I believe you probably know, just adding for other new to the old car/truck repair forum readers. DJ1 point

-

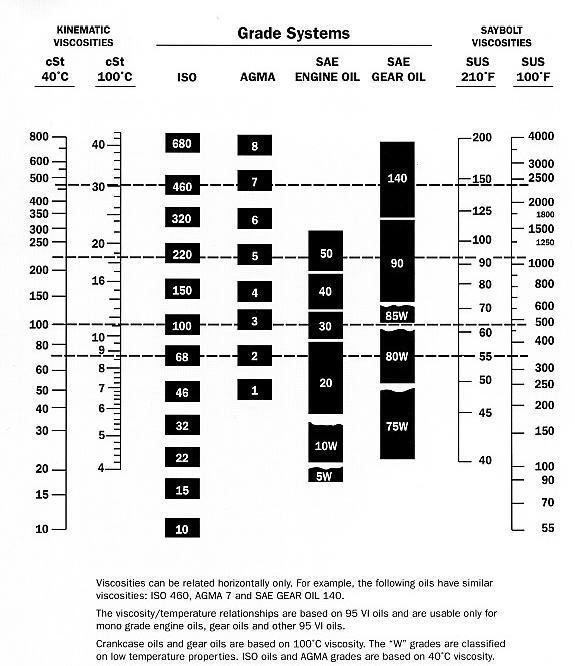

I also was in similar circumstances a number of years ago trying to find a local supplier for plain old gear oil. I spoke with a local business that specializes in rebuilding transmissions and they suggested using SAE 50 engine oil... I chose not to follow their advice ; as I live close to to the US/Canada border I picked up the gear oil at Napa in Cut Bank MT... Sometime later I came across this oil viscosity chart.1 point

-

1 point

-

Welcome aboard...........try tractor or similar type places, also truck repair shops........the standard 3 speed trans takes 2 & 3/4 pints of SAE80 Fluid Gear Lubricant, fill to bottom of filler plug hole.........the diff takes 3 & 1/4 pints of Rxtreme pressure Hypoid Gear Oil of SAE 90 for temps above 10 degrees, below 10 degrees use SAE 80 fill to bottom of filler plug hole, do not overfill gearbox or diff......on the diff check that the rear axle air vent is clear and clean of dirt, dust and crap....if obstructed.....clean...........P15 Plymouths had a standard 3 speed transmission using a clutch between the engine flywheel and gearbox..........Fluid Drive was a fluid coupling that took the place of the clutch between the engine and gearbox.........as far as I am aware all 3 speed transmissions should only ever use OIL.........nothing that is called a "fluid" should be used.......not being pedantic just trying to explain that there is a difference and you may get the wrong lubricant if you are not careful...............I would strongly suggest getting a workshop manual and NOT a CD version but an original or reprinted paper copy..........regards from Oz........Andyd1 point

-

1 point

-

beating a header full of ding probably does about as much as a pair of skivvies restricts a fart....but then its all hot gases...1 point

-

My weather report is no rain...just clouds....hope hope hope. Oh the first Truck showed up today....the yellow panel in the flyer. I mentioned the weather. He looked at me and said "I don't care...it's a truck...it'll dry off." 48D1 point

-

I got some help for an hour and a half this morning. I got the stand for the m/c and 90% of the disconnecting done before he got here. We got the cab off clean and decided it was a bad idea to lean it on its back since the lower panels are not structural and all the weight is in the front. So we put it on some beefy jack stands where I can still get underneath to do the finishing work. The transmission is sitting right there, ripe for the plucking, and my gaskets and seals are here for it too. Taking a lunch break right now trying to rally to get more work done today. The firewall, floor, and frame are going to keep me busy for a week or two in the driveway. Hopefully I can get the engine shimmed up by the oil pan so I can pull the trans while the sun is shining and I can make noise wheeling the crane around the driveway.1 point

-

I don't have the info in front of me, so I am going off of memory - but I believe the 265ci engine was advertised at 136hp with factory dual carbs and dual exhaust in 1954 (the same year the Hemi was introduced at 133hp). This would have been for larger trucks 2-1/2T and up.1 point

-

1 point

-

I believe the "SPITFIRE" head was Chrysler only (not Desoto) and I believe there is no performance difference in the Spitfire head and the non spitfire head. The spitfire head is just prettier.1 point