Leaderboard

Popular Content

Showing content with the highest reputation on 02/14/2019 in all areas

-

Pouring down rain this morning. Flood watch in effect. Headed to the shop in the dark when out of nowhere a huge fallen pine tree is hanging into my lane. At 45 mph it hit the roof on the passenger side near the corner of the windshield. Was expecting broken glass and significant damage. Nada.....zip....nothing. Not even a scratch. Got to love that old Detroit Iron. I am positive an impact like this would have messed up a newer truck. And yet the only evidence is a few pine needles. And an elevated heartbeat..... Old Pilothouse trucks RULE! Jeff8 points

-

5 points

-

413's only came in the 4 ton "Y" series Dodge trucks....and where more powerful than the original engines in the early M35 gas engines.2 points

-

2 points

-

Excellent... Excellent "How It Works" M-6 transmission video Keith... it shows it all and easy to understand too. Thank you!2 points

-

Its very clear why Tim Kingsbury and a number of others stay away from this Forum. Most likely time to lock this useless thread. Good rittens..2 points

-

2 points

-

2 points

-

2 points

-

I'm sorry if someone already posted this, but the photo is just amazing, as are others on the Petrel website. This tractor has been under the sea for 75 years! The Hornet was discovered a couple weeks ago at about 18,000 feet under. It's amazing how well preserved it is. There is one where someone's jacket is still stuck in a hatch. Here is the URL: https://www.paulallen.com/Indepth/Petrel/discoveries/uss-hornet-cv-8.php1 point

-

Sometimes people true up the surfaces on the intake and exhaust manifolds themselves. Not sure about the surfaces on the block where the manifolds mount. If you did that, it would of course require removal of the studs. The crankshaft main bearing bores/saddles occasionally require line boring to get them all to line up with each other, but that's not a must on every engine. It just depends on the condition of those bores. I don't know of any other surfaces on the block that are routinely machined (aside from things you probably already know about, such as cylinders, valve seats, etc.). If a gasket surface, such as the ones you mentioned, is damaged, of course the shop can machine it to correct the issue, assuming it's not too badly damaged. There is another thread on this site (can't recall which thread), where the gentleman describes having to braze some damage (maybe a crack?) to the thermostat housing mating surface on the top of the head, and his shop machined it nice and flat again.1 point

-

Yeah, he had the original tanks and speedo but otherwise it's what you see. He was asking $12k for it or $12k for that '06 something or other that's in the pic behind it. I almost offered him $12k for the pair but I didn't want to end up looking like a jack-o-lantern. Ditto on the barn dust. Dig this.. You Tennessee boys have a sense of humor I can relate to!! ? https://memphis.craigslist.org/cto/d/crittenden-barn-find/6806218489.html1 point

-

1 point

-

I am on the side of replacing manifold studs and bolts as a set during a full engine rebuild...I've seen these corroded where there is pitting along the shanks, even though they were still useable...since exhaust fasteners see the most heat, any significant corrosion can lead to failure from yielding or fracturing, which is not good for manifold sealing. I have replaced individual studs and bolts on engine repairs, as inspection of stud and bolt surfaces showed no pitting or obvious signs of stretching, and those repairs lasted for over 10 years. In either case, the new studs and bolts were almost as rusty looking after several years of use as the originals, so it was hard to tell at a glance which were new and which were vintage1 point

-

Yea an oil leak would kill the sale on a pan. ? A lot of non original parts on that one, at least it has the original barn dust which always drives the value up.1 point

-

Well here is 1 turning 5500 revving no load. But I guess it would take another 500 to impress you. I suggest you Call George Asche to discuss a 6 k RPM redline possibility.1 point

-

I would like to see or hear evidence of a flathead 6 turning 6000 RPM's1 point

-

1 point

-

Seems to me that deferring to Mr. Asche and Mr. Kingsbury's experience is worth more than all the wool-gathering and head scratching the rest of us might do. It would be interesting to see actual fuel mixture data from each cylinder, though.1 point

-

1 point

-

Well, all I can say is this has made for some interesting reading with my morning cup of coffee.1 point

-

simple, you have to take the answers in context with the question posted in post #7 If you ever removed the oil pump in a flathead you would have timed the gear to the cam in regard to the distributor or indexed the tower as the oil pump mates to the cam and drives the distributor...on a total rebuild, you will have to align all from scratch on assembly and THAT IS ONLY IF YOU WISH YOUR WIRING ON THE TOWER TO BE THAT OF THE BOOK...you can do it anyway you want, AND as the mopar LA 8's (even big blocks) you mentioned have an intermediate gear that IS TIMED on install to the cam for the same purpose this gear drives both the distributor and the pump...you simply just index the oil pump on any of the six drive flats....slant six as you mention is yet a different setup as both the distributor and oil pump have their own individual gears running off the cam at just less than 90 degree to each other. Of the four mentioned engine groups in this post, only the LA has an internal oil pump....the rest are externally serviced.1 point

-

1 point

-

Ok! Wait a minute. I see this argument all the time. Not picking on Frank but the air fuel mixture is set in the carb. It then gets delivered to the manifold and gets sucked to which ever port is calling for it. If the mixture is correct as it enters the manifold, how can it change to a leaner mix in a closed tube? If it gets leaner where does the gas go?? Seems to me unless air is entering some where south of the carburetor. I will stipulate the center intake might be provided a fuller charge because the fuel air has to travel a shorter and more direct path to the cylinder but if all cylinders are pumping equal volumes the charge would be the volume and contain the same amount of gas. I can see were a second carb shortens the distance and may make the system more efficient but since each carb is only half the cfms based on bernullis principles and venturies effect both charges might actually be leaner than that provided the single carb. Things that make you go hmmmm. And if distance were a critical factor please explain the long runners on slant sixes and the long ram intakes on the 413 dual 4 BBL intakes.1 point

-

That front crankshaft pulley felt started in 1953 I believe.I don't think it used on all models of flat head engines. The backside of the hub/pulley had a stamped steel cup with four prongs that held the felt from turning in the pulley. The felt rubbed up against the 1/2" flat on the timing cover....it acted as a dust seal.1 point

-

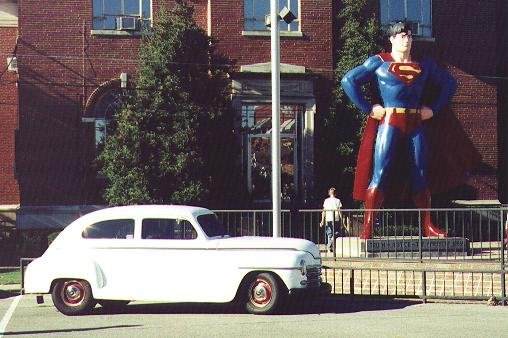

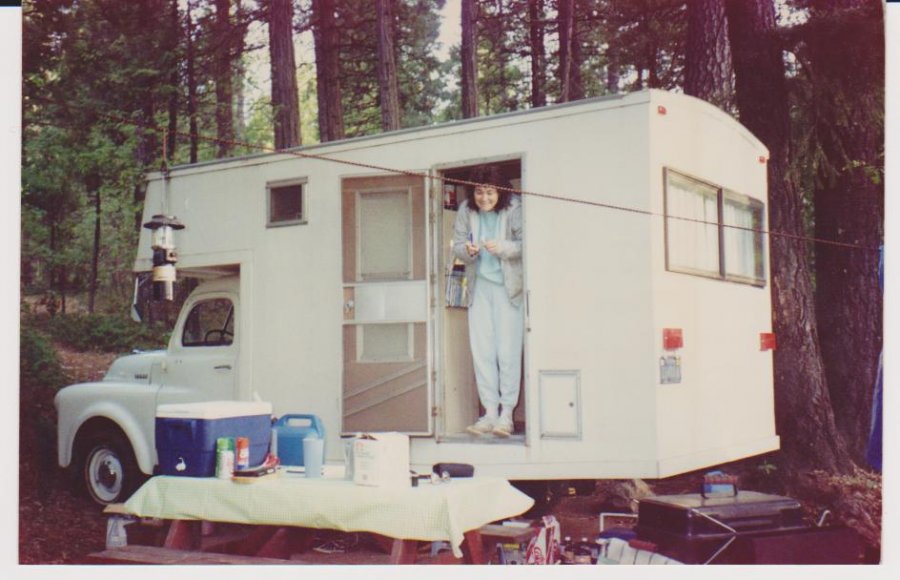

Don't drive during winter here in Wisconsin but do get around during better weather. 1-Driving thru Metropolis IL, 2-Memphis, 3-Arrive Daytona, 4-Daytona Beach for the Turkey Run, 5-Talledega Speedway on the trip home. Also have some photos somewhere of the car at Operaland, Don Garlits museum, and in Daytona Speedway pits. 3700 mile trip, just my wife and my 48 P15, 440 powered.1 point

-

I saw the announcement of the discovery on the news yesterday, and was equally enthralled by the photos, especially the tractor. The ship must have gone all the way to the bottom on a fairly even keel. Amazing how clear the water is down there, the photos could have been taken on the surface if we didn't know better. Thanks for posting the link!1 point

-

1 point

-

Actually you would be better off with longer rods. If you don't have new pistons yet, have some made with a slightly higher wrist pin + you get a modern piston / ring design. If I ever go through my 230, I'll install 218 rods with shorter more modern pistons. On edit: assemble 1 cylinder and see how far the piston actually comes out. Some of these engines don't come all the way to the deck, might be ok with fly cutting the piston a little???? But then you still have a 4 ring pack long heavy piston.1 point

-

Got an update. I called a couple of other machinists and they couldn't tell me how much interference there should be. I even found a copy of a 2006 edition of the AERA connecting rod manual, and while it provides this kind of info for some engines, it doesn't for our flatheads. I then called Sealed Power yesterday and they told me the bushings need to be installed with about 0.004 - 0.0045" of press fit. I thought the rep didn't know what he was talking about and so did my machinist. That sounds like a ludicrous amount of interference. So I dropped into another machine shop - a big outfit - and talked to their head machinist, who has been doing engine machine work for 40 years, and he said that was about right for bronze bushings, which is what these are. I thought they were going to be steel-backed bronze, based on the description on NAPA's website, but they are bronze all the way through. I know this because I got a hold of three different parts (three different part numbers - one standard outside diameter and two different oversizes) and looked at the parts myself, and they are bronze. Anyway, the machinist said if the interference is only 0.0015" or so, which is what I was thinking, then the bushings will "fall" out. He also said burnishing them to expand them out against the rod bore is the best way to do it, but not many shops have the setup to do this, but he does. He also said such a large press fit is not needed for steel bushings, nor is burnishing. I got the impression from him that steel bushings only need about 0.002" interference, bit I'm not sure how accurate that is.Further confirmation of the tight press fit for bronze bushings is the fact that when I measured the three different bushings I got a hold of, the ODs were all 0.004 - 0.005" larger than advertised online (again by NAPA as well as other sources). I guess when the OD is stated, they mean the final installed OD, which is essentially the size of the rod ID, but that was not clear from the specs they provided. I think I'm starting to understand how this works, though.Since the machinist I spoke to this morning really seemed to know what he was talking about, I went and picked up my rods from my previous machinist and am planning to take them to this new guy.I'm posting this in hopes it will help someone else at some point, maybe even me1 point

-

1 point

-

1 point

-

Yeah they flooded the market with twincams plus the chopper tv craze is over nobody wants bikes any more but they’re still not making any more 1948 springer hardtail panheads- the dreamiest bike ever short of a vincent black shadow.1 point

-

I've seen a few members do this recently, and I recall seeing this on the HAMB back before it got overrun by crazy ppl: putting "Build Thread" in the title of their build thread. Since a sticky on the Links to Building Threads would require constant moderation of the thread itself, members can put "Build Thread" in the title of the thread that their major work is being shown...that phrase can be used in the search engine to produce a directory of sorts that does not require moderator oversight. I have edited my build threads to show this info in the titles to get the ball rolling...1 point

-

Just stick with 54 on everything and you will be fine. 53 is a whole different truck...1 point

-

1 point

-

This appears to be the driver side setup...the passenger side should be a mirror image. It appears that the parts you ordered would be correct as they are mirror castings. Scanning the parts manual, part numbers for the support plates are different for left and right for 1/2 and 3/4 ton B-series...possibly done wrong at the factory, possibly "upgraded" by a previous repair...1 point

-

1 point

-

1 point

-

.0001" to .0004" spec for a 1953 Dodge 2-1/2 ton 265 same as all 25" engines....1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Nice, I've got a 1934 version that my grandfather gave me probably 40 yrs ago, he replaced it on the car he had back in the 1940's as the area where the actual cap attached had corroded and the cap came loose so its only fit as an ornament........andyd1 point

-

1 point

-

1 point

-

The fuel line from the fuel pump to the carb. ran within 1/4" of the manafold. I rerouted the line and have not had anymore problems. Thanks for all of your responces and sorry it took so long for me to post mine. And yes it is "Standing Elk" don't do much runnin anymore. LOL1 point

-

0 points

-

So let's consider dual carbs for single cyinder engines. Re read, I stipulated that three and four are probably best served and most efficiently provided for. But if number 1 and 6 are pumping the same amount of air they must by the principles of fluid Dynamics get the same intake charge assuming valve timing and intake valve timing lift and duration are the same. Is it possible that some fuel falls out of the vapor state sure. If it's significant where does it go. Does it pool in the intake?? If it does might this not allow the pooled fuel to cause the rear cylinders to run rich under acceleration? And conversely do the front cylinders run rich while braking?? It's like tire rubber. We know it wears off our tires and others tires but shouldn't it accumulate at the side of the road? Other than chunks of truck tires, you don't see rubber laying around. Where does it go?0 points