Leaderboard

Popular Content

Showing content with the highest reputation on 01/13/2019 in all areas

-

2 points

-

I believe, the same Michael Warsaw that caused a lot of arguments on here a few years ago.2 points

-

I remember it like this: 15--is too young 36--is too old 24--is just right Andy1 point

-

Canada's not that far from me, right?! Jump in your car and get down here, I could use the help!1 point

-

1 point

-

The bow in your axle may be normal. I don’t have knowledge of the larger chassis’, but on the light trucks the front axle even has a bend in it. Some see this and believe their axle is bad, but it’s normal... I had taken some photos of a spare 3/4 ton axle for someone not long ago but I must have deleted them for some reason. Can’t seem to find them now.1 point

-

1 point

-

It was a tight fit but made it at an angle. I actually wish it were smaller - won’t fit in the garage so I have to leave it outside under a tarp. The price was right though - was originally a dental production cabinet that was fully automated (dentures placed on a turntable and fed through automatically) with a cyclone dust separator/collector designed for continuous operation. I couldn’t resist bidding a penny for it and ended up getting it. I removed all of the automation (except turntable) and added glass and gloves. The cyclone unit does a great job filtering out the 70 year old grease and grime and leaves the aluminum oxide looking like new.1 point

-

they are to compensate for heavier loads and still retain dampening action within the built in travel limit...IF YOU are to over fill and extend them to the max you have driven out past the dampening action and simulating a straight solid mount, that is when the BEATING occurs and resulting damage.....logic prevails, everything in moderation...1 point

-

One thing that I have not read any one mentioning in this thread is the subject of the rocking motion of the pressure plate when the input shaft is out. I was told, very strongly, that before one removes or installs one of these units to place three wooden wedges under the pressure plate (between the bottom of the plate and the coupling housing) and run foot or so of bailing wire around the wedges and twist them tight with pliers. A groove in the rear of the wedge helps. What this does is to prevent the plate from rocking. Apparently, you can crack the carbon seal in the unit if it rocks. The issues is you will not know it until after it is all back together. Some times it cracks and takes a while until it starts leaking. So, I always place the wedges in before I pull the trans out if I am going to be pulling the coupling. Then when the trans is back in you just cut the wire and rotate the unit around and pull out the wedges. I use soft pine. James.1 point

-

1 point

-

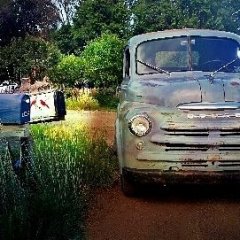

You own a ‘48 Dodge? Nice truck! I love the split 2 piece hood! I have an old Mopar truck stuck in my head too. Maybe someday. I would love to own one. If the right one comes along, at the right price...1 point

-

I got most of the parts blasted and cleaned up. While I had the blast cabinet running, I decided to throw the axle in and get it cleaned up. Came out looking great but seems to have a bow in it. Tomorrow I will get the straight edge out and take some measurements.1 point

-

I got the front axle disassembled today. I was pleasantly surprised with the condition. King pins came out easily and had almost no signs of wear. I had already ordered a new set - had I waited I am not sure I would replace them. Drums came off easily. Bearings all look new. Drums are in great shape.1 point

-

The parts book I have shown info out of is a factory 1946-48 Dodge car parts book.1 point

-

1 point

-

As far as carb kits go, I use the Hy-Grade kit from Standard Motor Products - the number of the kit is 101A. Napa also has a kit - 2-5066A.1 point

-

No bushing fits into a bushing in the lower part of the coupling hub. If you see a bushing down there remove it and see what you got .... I've replaced both of them on a couple different jobs. The FD hub is all steel and accurately machined for the small and large bushings. One of each ...that's it.1 point

-

Glad you found it. Sometimes it seems like the factory had kids doing the number stampings - especially on the frame serial number and the third member ratio numbers. I believe the 4.30 ratio was the factory standard with the very rare 3.91 and the 4.89 as options.1 point

-

1 point

-

Just got this little gem in the mail today. In my state the YOM plate must have at least one letter. Not an easy find as most plates from that period are all numbers. This was the only one on eBay. Nice shape too. I only need one plate. Can't wait to mount it. ?1 point

-

Once I made it to the shop, I backed off the '48 under it's own power. The emergency brake worked great! I was able to drive it in reverse (of course) and 1st gear. The sound of it reminded me of my old '55 flat fender Power Wagon. That stirred up some emotions. Only this time I won't be selling the truck. Till death do us part! ? The carb leaks badly, so that will be first priority.1 point

-

1 point

-

1 point

-

Full flow filter looks like this. Has a pressure relief relief valve in the tube in the center that will allow oil to pass if the filter element is plugged. A pipe plug must be installed to make it function correctly.1 point