Leaderboard

Popular Content

Showing content with the highest reputation on 07/01/2018 in all areas

-

Hey Bud, Personally, I would leave it alone. The phenolic piece they are riveted too is fragile. Any attempt to tighten the rivets may crack or break it. However, if it bothers you that much, try a small brass drift and lightly tap on the terminal side of the rivets. Or you can try a small dab of super glue on the terminal side. As long as the rivet is not in danger of turning and contacting the other terminal, or coming off the board, I would leave it alone. Joe2 points

-

I find that whatever height they are, if I add casters so I can easily move things around, they are then about right. Being about 6'2", I find that most things are too low for me as they come. Casters solve 2 problems.2 points

-

Well, today we finished the brake job. Kris had the shoes relined locally, as well as cutting the drums. We get it all back together this morning, on hot and humid day. It was good to see the truck out of the garage again. Kris did quite a lot of work to it over the winter/spring. I helped him with some of the more technical things, but he did most of the work. Atta Boy, Kris. You done good... Our test run this morning...2 points

-

My folding table and folding sawhorses are at 30, my workbenches and work tables are at 36, same as my countertops...tho I built a work table for Dad that is 42 so he could do close up work without stooping over. btw one of the lean projects I did at a previous job was to get all workbenches, tables and carts the same height...we were adjusting heights on tables and benches to our purchased carts so that we could minimize lifting required...some thought it was silly at first, but eventually everyone liked that we could slide heavy objects on and off carts onto tables and workbenches without lifting2 points

-

with so many people converting to disc brakes, there have to be a number of forum members with their old drums taking up space under the workbench. If you are on Vancouver Island I could easily help you but freight rates into the USA are prohibitive.1 point

-

1 point

-

Probably not unless you mill your head. Most of the additional power came from higher compression.1 point

-

I agree—that phenolic sheet is semi-fragile at best, and age won’t make it any stronger. I certainly wouldn’t recommend pounding on the terminals too much. When connecting the wires to the terminals, try holding the terminals with a pair of pliers in the “east-west” plane while you tighten the screws to the terminals in the “north-south” plane. There’s most likely minimal movement at that junction, if any. So, I wouldn’t worry about it. Regards to you . . .1 point

-

I usually check here first also CC.... I am not a mechanic and I have found a few who will "dumb it down" for me and it builds my confidence. ? the manual doesn't always cover my scenario. good luck and report back!1 point

-

1 point

-

See Merle's "Pilot - House Friends" post from August ’17 for background. Last summer/fall, between a couple of trips to the clinic for follow up care, Eddie enjoyed sun on his face and good asphalt under his toes – at most 50 miles. In early November a clogged artery (idle tube) and another bum knee (rear wheel cylinder this time) stopped him in his tracks again. It’s pretty clear discharge from the nursing home was premature – but it was fun. With winter approaching and a list of ailments to address, I exercised power of attorney privileges and stuck him in rehab for more treatment. Eddie got out today! Highlights of an 8 month rehab stint: · Shedding a few pounds of crud from under-carriage and a decent cleaning under the hood and inside the cab Prepped and painted cab floor; added sound insulation to most of the cab; and re-covered seat · Refurbished original parking lights and replaced 60’s era front turn signals with 40’s era Arrow brand signals · New tail lights (including passenger side addition) and rear LED turns · Installed restored 802 radio and 40’s era speaker; plus a hide-away antenna · Complete wiring harness; tachometer added; temp gauge and choke cable repaired; NOS dimmer and panel light switches; and speedo cable · Rear brakes – re-sleeved cylinders, drums shaved and shoes re-lined · Carb cleaning/adjustments; fuel filter; and a few other mechanical tweaks; · Other miscellaneous quality of life items. · (New windshield and painting visor are on to-do list) Eddie won’t win a street fight at a car/truck show, but he is a solid old-codger with an attitude. Hopefully we’ll get some work done and have a little fun before he demands time off for bingo (or another breakdown). A BIG shout out to Merle for his guidance and help. Thanks to B1BKeven and ggdad1951 for their contributions. And thanks to forum members for sharing hundreds of pages of insights and ideas.1 point

-

Mac’s Antique Auto Parts (a division of Eckler’s) carries it. Also, you can probably get some as an auto glass shop. I’ve used friction electrical tape along with black silicone sealer with good luck. Just a suggestion. Regards to you . . .1 point

-

usually a sign of seal deterioration due mainly to the environment in which the rear seal operates. That and the every present moisture in the area as the piston is moved forward and back exposing the end of the cylinder, this along with the boot itself with a slight gap on the plunger will itself act as a vacuum and suck in dust and such....a disassembly and clean up and installing of a new kit...you ought to be back in business....1 point

-

1 point

-

1 point

-

the donkey rider could well be yourself....based solely on the ass-backward position of rider, you will eventually arrive at your destination but have no clue how you got there.....as for whatever is written, I have no clue or any desire to read as I truly do not bother with any political satire as to fully enjoy you MUST SHARE the comics' belief... anyway, it is always more fun to laugh at yourself along with others rather than just having others laughing at you....actually a more valid name for this in the deep south would be "goober driver" (use urban dictionary)1 point

-

Just a smooth running flattie. See Kris’ post about Eddie’s Rehab1 point

-

All that time working with you on your truck and I had no idea you had named him Eddie. ?1 point

-

1 point

-

That PW that was shown earlier. I had a 56 C-3 in the mid 90s. What a fool I was to sell it.1 point

-

I have seen the quality of your work and I really don't think the hight of any work bench will result in an improvement.⚒️1 point

-

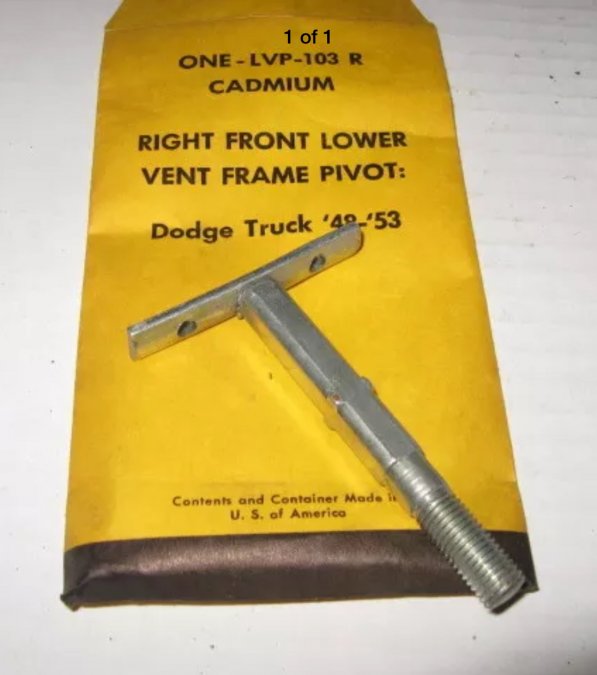

For future reference, this is an exact fit. And I will also note that the left and right part numbers turn out to be the exact same part. I ordered both to see what the difference would be. Spot welds on these are not great, hoping they hold on for my life time. Today I will drill out the old top flange, clean the frame and install the new post. Wondering if my rivet gun will work for this.1 point

-

To bar the engine over, you can typically use the nut on the front of the crankshaft, or use a pry bar on the ring gear against the bell housing. However, if the engine is seized you won’t be able to bar it over to access all of the clutch bolts. The other option, since it’s out of the truck, it to use a punch and drive the dowel pins into the bell housing a little bit, so they’ll clear the block, then lift the bell housing up over the top of the flywheel.1 point

-

On positive grounded car the wire to the distributor in wire should go to the positive marked terminal on the coil. DJ1 point

-

I did get started on an adapter for the tire changer, but wouldn't ya know it, my neighbor wanted his ATV tires swapped out...I was still kinda dragging from a lingering sinus infection, and coupled with the 100° temps, I was totally gassed by dinner time, so that's been put on hold again for a little while. A week later, I got back to organizing my parts inventory I started over a year ago. I need to clear out that workspace to prep two exterior doors I need to replace on the house, so I was motivated to move this back to the top of the priority list. The work table was covered with layers of boxes of completed project parts and supplies that dated back to last Spring...once I got that cleared off and squared away, there were the rotting boxes and ripped bags and rusty coffee cans and splitting butter tubs of bolts, screws, etc that I had collected from a few trades back in 2012. It took the better part of 2 days to go through everything, identifying hardware that belonged to certain parts of the trucks, hardware that needed to be scrapped, and hardware that belonged elsewhere. There was quite a bit of International Harvester parts mixed in with several bags of Dodge Truck bolts, as well as lawnmower parts, electrical junction box parts, and generic sheet metal screws. I filled up the big coffee can with rusty hardware that was not worth using , probably about 20# of scrap to sell. After separating the good from the bad, I realized that I needed to get all the door hardware out of the deteriorating plastic containers...so on my next trip to town, I picked up a few of those hardware organizers and filled them up. I also had several years' collection of peanut butter, mayo, lemonade mix and peanut plastic containers that I finally got to use, and several larger tubs to compartmentalize all this hardware. It's been a tedious task that was long overdue, but now I have an organized hardware inventory and freed up a shelf on a storage rack...MISSION ACCOMPLISHED1 point

-

1 point

-

why do you call him a chainsaw carver..???....that looks nothing like any chainsaw I have ever seen....0 points

b.jpg.ae5922de4d1b6d52f250d4d3dae7e1f7.jpg)

b.thumb.jpg.cae689afb29a5b5e59e5d27e7e4d87a5.jpg)

b.jpg.b5f92c8f57e04d2b4984e10e456e8877.jpg)

b.jpg.b5314a9f32f200a6ecfecc90ccf1e602.jpg)

b.jpg.3b39d6672d05937fb6d9105da053322b.jpg)