Leaderboard

Popular Content

Showing content with the highest reputation on 02/08/2018 in all areas

-

Hi I'm new to the forum and thought I'd let people know what my truck looks like. I bought this 1952 dg1 08 thinking I would put it on a Dakota frame and a v8 or Cummins 3.3 that I have. But I think it is too nice to chop up. So I've ordered new seat vinyl and padding from Roberts motor parts and ill drive it as is. The original wheels tires and hubcaps were in the back of the box when I bought it. And he had a brand new tailgate from a same year 1 ton he threw in also. The 1 ton tailgate is wider than this trucks. In the meantime I've found rougher 1951 Fargo fo1 08 that ill start my other project with.5 points

-

Back in the sixties I used to tell my friends that they should never knock a Stovebolt Chev as they would eventually knock all on their own. However, at this late date the inherent weaknesses of each company's designs are well documented. It was our duty as teenagers to find these weaknesses and we all worked hard at it. That a car of the late 40s/ early 50s has survived this long has to be some sort of tribute to its manufacturer. I am now on my fourth 50 Plymouth in over 50 years and have covered at least 300 000 miles under all weather and road conditions. I have never tired of driving this particular car with its (to my eye) good looks, gorgeous dashboard and unsurpassed reliability. Rust killed the first three but the present one is never exposed to salty roads. It should outlast me. Good luck.4 points

-

2 points

-

This might help: http://www.crankshaftcoalition.com/wiki/MOPAR_inline_flathead_engines2 points

-

2 points

-

2 points

-

Thanks all for the compliments. It is what some call a salad. The frame is from an open cab military WC truck although both open cab and closed cab non-winch frames are Identical. The pick-up box is a short side box from a 1954 Funtional Design 1/2 ton truck. I had it modified it to look like a military box and added a pair of original WC 1/2 to military fenders. The tailgate is a 39-47 Dodge Civilian one that is a repro from Mac products which I bought over 25 years ago. The military tailgate had no lettering. It is a quality build repro which weights within ounces of the original that came with the 54 box. The Dodge lettering was more massive on the 54 box so thus I went with the 39-47 lettering which matches the 2 Dodge name plates on each side of the hood. The cab is a true Military cab and not a civilian cab. Replaced the 23” 230 with a 25” 237. Original type repro. wiring harness original 6V Gen and VRY regulator that came with the truck. The Starter is a newer 6V MAW-4030 in place of the MZ-4115. Changed out the third members to postwar units which are a tad stronger than prewar ones. Brakes are all stock and work well. The wheels and tires are 900-16 vs the original 750-16 wheels and tires. As I have said in other posts on the forum, this spring I plan on swapping out the 4.30 ratio third members for a set of 4.10’s. I then will go back to the 750-16 wheels and tires. Will only increase my RPM’s about 103 to 2545 from 2442 at 55-60 MPH’s. Again it’s a “Salad” but hey it’s “My Salad”. LOL.2 points

-

I know not everyone goes between the car side and the truck side of the website.....so I just wanted to remind all the car guys, as always, you are invited to the Tailgate BBQ! Its a fun way to meet a lot of the folks on this forum and a great way to learn about the vehicles. Sometimes a guy has a running chevy or ford (cuz he's still building his dream Dodge) and wants to know if he can bring that....of course! Follow this link to the truck side and join the conversation......I'll have the flyer ready to go soon. 11th Annual BBQ If you look at links below my post (I understand the links don't show up on the mobile site) you can read the older truck show posts from 2008-2017. Hope to see you there! Tim aka 48Dodger1 point

-

Hi, I am wondering if someone can please help me I have an old car 1954 dodge Kingsway business mans coupe is what I was told it is but am not sure what model it is so I can buy parts what I see on the car is vehichle # 97004101 model d39 3 cpe, body no. 27 but I am unsure what model this would be a coronet, custom, meadowbrook, royal or sierra is what I was told I need in order to buy parts.. sorry I am not very good with this sort of thing. Thank you in advance for any help.1 point

-

At the risk of repeating my self I am going to repeat what I sad in a similar thread. I believe most of the Mustang II cross member kits have serious design flaws that will lead to failure if the car is used as a driver. If you think you must replace the front suspension then get a frame clip from a wrecking yard from a vehicle that was designed by real automotive engineers. Below is my experience with a Mustang ii conversion. From personal experience I am not a fan of the Fatman/Heidts/ etc style Mustang II kits. This style of kit uses a single 1/2" bolt as the pivot for the lower control arm. I put a Fatman kit in my 1970 Mercedes when I installed the Ford 4.6L V8. At about 50,000 miles the lower control arm bolt on the right side sheared off where it exited the back of the cross member. My wife was driving the car when it happened, fortunately she was close to home and only driving about 20mph when she went to stop for a traffic light, heard a "bang" and the car dove to the right. The lower control arm bent but did not come loose so the car didn't fall to the ground. When I pulled the broken end of the bolt out of the lower control arm you could see a vertical strip of fresh break about 1/16" of an inch wide, the rest of the cross section of the bolt was corroded. This is classic fatigue failure, a month before the bolt broke we had driven the cae from Portland to Reno for vacation at highway speeds, through the mountains. I know the bolt was seriously compromised during that trip and had it broken at 60mph on a mountain curve I probably wouldn't be writing this now. It's been 2 years and 10,000 miles since that incident and I recently pulled a bolt for inspection, it is showing signs of fatigue cracking at the same location it broke the last time. The other problem is the bolts tend to seize in the cross member from corrosion, mine were corroded in place and it took two days, $100 worth of drill bits and two 1/2 inch drills to get them out. I will not use another one of those kits on any car I build.1 point

-

The entries in the table at http://www.crankshaftcoalition.com/wiki/MOPAR_inline_flathead_engines#1928-1959_Plymouth_engine_specs are not correct for 1933-34. I'd have to actually look up the correct values for other years to see if what else might be wrong.1 point

-

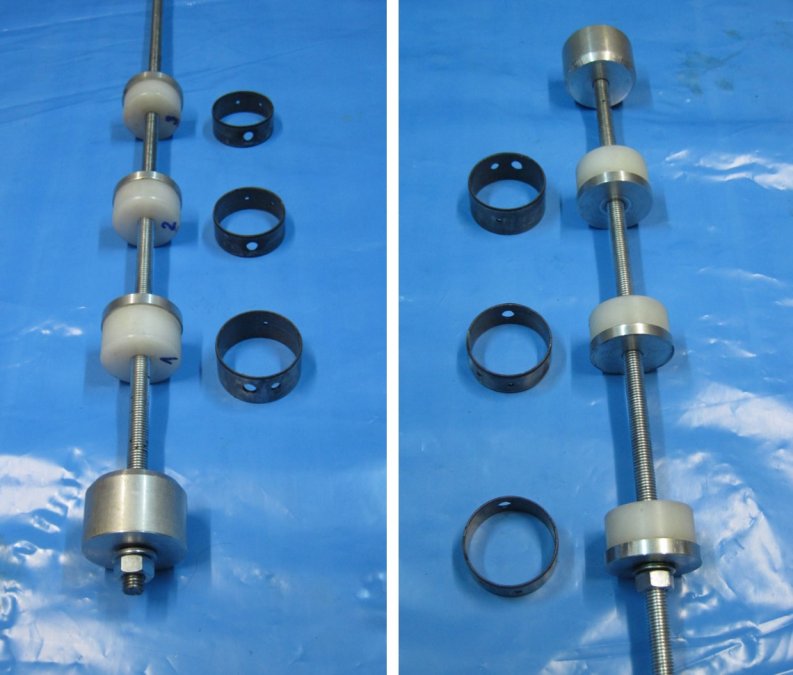

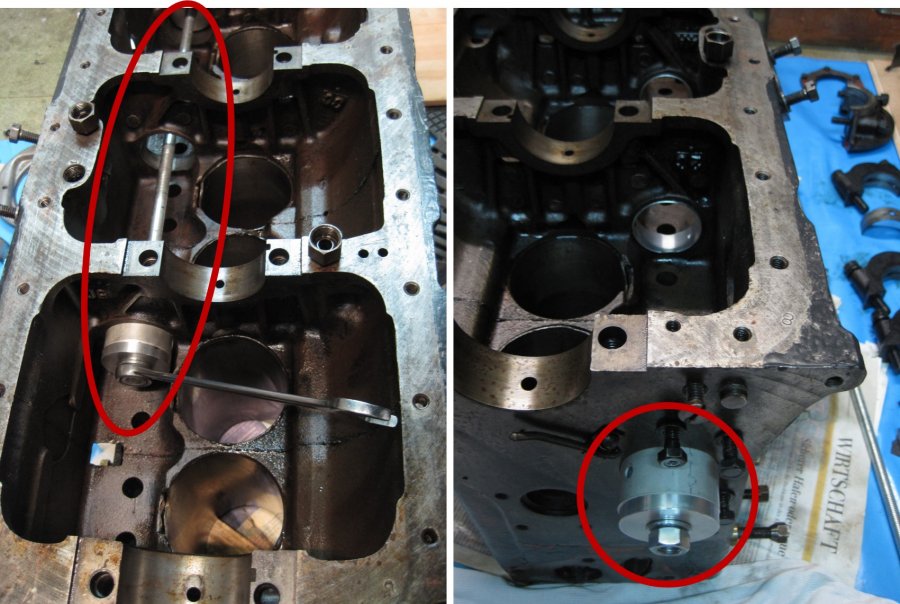

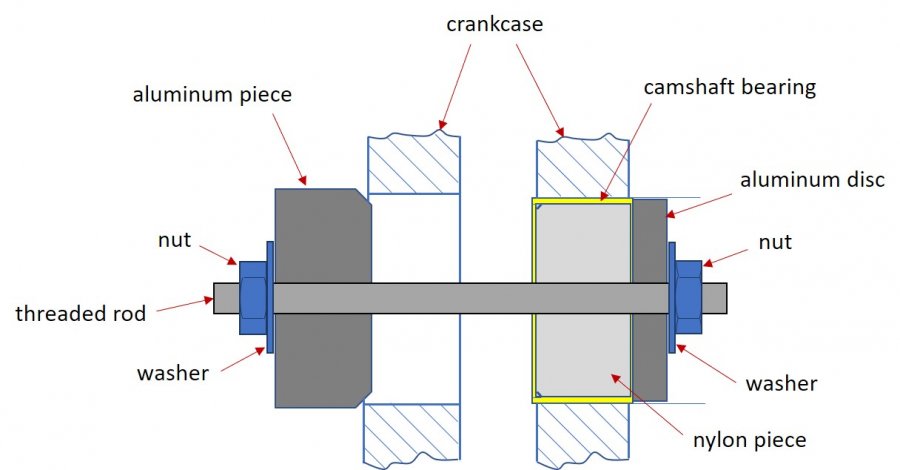

Ok, here is my home made camshaft bearing removing and installation tool. There are certainly more professional tools available . But for someone who does a bearing swap one or two times in a decade it might be worth to spent a little bit time and just little money to fabricate a tool himself. (By the way it is very satisfactory, if it works well.) I personally don`t like solutions that works like a slide hammer. If someone is not practiced, the risk is high to damage the new bearings. So this tool works as a press tool. A nylon piece fits pretty precise to the inner diameter oft he bearing. Just enough play that it doesn`t stick, once the bearing is pressed in. And close enough to avoid any tilt. A thick aluminum disc presses on the front edge of the bearing. The diameter of this disc is slightly smaller than the outer diameter oft he bearing. That to avoid any sticking to the bearing bore in the crankcase. Another aluminum piece with a large champfer works as a counter piece. And finaly a simple threaded rod is used to transmit the pressing force. Maybe that is nothing new but it did its job at my engine pretty well.1 point

-

1 point

-

This was my 1st outing and my last in 2012. It was the most unorganized show that I have been to in my 45 years of doing car events. People were rude falling down drunk. The hamburgers taste like a week old White Castle. You had to relieve yourself in the back 40s. The music was being piped in from a vacuum tube 50s radio. Evan had a starving HOARSE starting to eat the back end of a pickup truck!!!! Evan had an eagle flying around pooping on people and would fly in and take the hamburger out of your hand. We had a hurricane come through and took out the tent that provided the shade from the 120 heat. They give away pistons from a blown up engine for trophies etc etc etc!!! On the last but least NOTE!! They even had a fire pit that somehow they dug a 200 ft hole and the people they did not like, they pushed them in to see if they could hear a thump. OK!! I'm back on my MEDS!! SHOULD I SAY MORE!!! THIS WILL BE MY 6TH YEAR GOING. WOULD NOT MISS IT FOR NOTHING. ITS THE GREATEST SHOW ON Earth!! The only statement that is true in the small black print was the starving hoarse eating the truck. lol!!!!1 point

-

1 point

-

Awwwww......using a creeper for a temporary bench seat!! Wish I thought of that!!! I've always used a dang bucket. Nice find my friend. 48D1 point

-

hears the deal i have made a installler for this very issue..notice i said issue instead of problem to be modern.. but the fact is it is a problem...i machined the wrench flats off a crank bolt..welded a threaded rod inside.. now screw the the treaded part all the way down the crank hole.. use the attached large nut to force the pulley onto the crank..never hit with a hammer.. i will loan this to you...i want it back..i will send you a new crank nut..you want a crank nut or a plain crank nut.. jesse1 point

-

I'm sure rear axle is original. Top speed is about 55, if the Speedo is accurate.1 point

-

Also make sure the crank snout is clean w/o surface rust as well as the inside of the pulley hub. Lubricate those two surfaces too.1 point

-

I noticed recently that some fellows have thought Dave might have gone out of business as they couldn't seem to get ahold of him or get any response. He is still using his same e-mail address of krusn64@aol.com and his phone number is still (909) 239-7932. He lives in California. He said that in the last few months he has been busy doing an extensive remodel on his home and has not had time to do anything with making rubber parts. Said he has not viewed his email for a while. Had to move everything out of his house due to the work being done. He does have a stock of his rubber parts which he can sell from when he gets back into business. He is even working on molds for certain new parts which have been requested by some customers. He said please be patient and keep trying as he will be back into the swing of the business in a while. I asked if it was OK for me to pass this info along, and he said "yes". Hope this helps answer any questions. Bob1 point

-

Today I broke my determination to do all the labor on my truck by letting a good shop fix my exhaust pipe and muffler. They cut out about six feet of pipe and installed a quiet muffler. Engine sound is still there.but so much less and the sound is not harsh to hear. Total expense, $165.00. Getting ready for the BBQ drive. After the BBQ I'm going to stay overnight in Jamestown, a 90 minute drive, then on Sunday drive into Yosemite Valley. The water falls should be quite full by then. With the green grasses and colorful spring flowers it should be a great drive. Join me!1 point

-

I'm not advocating either path but I have both. My 47 has a GM front clip and my 49 has a factory IFS. Here are a few of the PROS to adding a modern suspension: 1. Going from king pins to ball joints ++++++ 2. Power steering if you want without the kludge of a Cavalier R&P 3. Better Geometry for highway use (ability to have more caster and split, anti dive characteristics......) 4. Getting the steering box out of the engine compartment (engine swaps) 5. You can set your vehicle ride height to exactly where you want it with the control arms riding in the stock position 6. Correct wheel position (centered in fender) Not all vehicles have this issue CONS of a clip, PROS for keeping stock setup: 1. If you don't know what you are doing you will ruin your frame. This is not for the novice or faint of heart. I've seen some SCARY clip jobs... 2. Don't underestimate the amount of fabrication involved. Clips could end a lot of projects prematurely. Don't believe the hot rod shows on TV that make this stuff look easy, it isn't. 3. The stock front suspension is pretty darn good, especially after adding disc brakes and shock mount mod. 4. You can add power steering (a lot of sacrifices doing so). I am biased here cause I hate R&P steering. These aren't sports cars 5. Some locations that do annual vehicle inspections will balk at these type of modifications. 6. Track width of some clips is too wide. I had to install Fatman narrow control arms on my 71 Camaro clip in my 47 = $$$$. If you do change the suspension, I agree with using a Dakota or GM over the Mustang II. Either way you're going to have to lop the frame rails off at the firewall so why would you put a Pinto front end in with R&P? FWIW (free opinions are worth what you paid for) Adam1 point

-

Back on the farm I had a one acre pond stocked with fish and used for swimming in the summer. Every summer I would drop one quart of motor oil in the pond. The oil floats and would migrate to the outer banks where the water was stagnant and retard the growth of mosquito larvae. Be it right or wrong it worked.1 point

-

You might keep in mind that most, if not nearly all, engine builders suggest strongly that timing chain and gears be replaced as a set. And bleeding cash is the name of the game. How else are you going to spend 20k on a truck that will bring 7 or 8k on a good day?1 point

-

1 point

-

1 point

-

1 point

-

1 point

(1024x768).jpg.46915f4d16cf2229c85eb950bacefe72.jpg)