Leaderboard

Popular Content

Showing content with the highest reputation on 08/12/2017 in all areas

-

So far sooooooooo good ! She's back together now and running surprisingly strong. The throttle response is lightning fast and the engine pulls harder than the 251 in my old Yellow truck. I am happy happy happy !!! I'm going to drive it for a couple days and then check the compression on all cylinders.8 points

-

I may have related this before so bear with me. My uncle had a 47 Pontiac. I rember as a kid a guy with a panel van truck showing up one Saturday morning and working on the Pontiacs flathead 6 engineengine. It was smoking and making noise. The head was pulled and a diagnosis of broken rings scored cylinders and piston slap was rendered. Along with a worn connecting rod. With a tool that looked like a small oil well derrick, one cylinder was bored .020, one was bored .030, and one was honed, and a new standard piston was fitted. This was the one that was slapping. So the engine went back together with four standard pistons, one 20 over, one 30 over and one new standard con rod bearing on a slightly polished crank throw. Ran fine stopped smoking and was quiet. I guess at 6.4 to 1 car, and not much than 2800 rpm , these old lumps are pretty tolerant of driveway repair techniques.3 points

-

"So far sooooooooo good ! She's back together now and running surprisingly strong. The throttle response is lightning fast and the engine pulls harder than the 251 in my old Yellow truck. I am happy happy happy !!! I'm going to drive it for a couple days and then check the compression on all cylinders. " Reg,why tempt fate? You are happy with it now,so how are you going to be any happier if the numbers are high than you are now? On the other hand,if just ONE cylinder is just a tiny bit low,chances are you are going to be bummed until you fix that one cylinder. The old expression "leave well enough alone" is still a bit of wisdom we all need to heed occasionally.3 points

-

A trick I learned from an old man...................... If it seems you cannot get the castle nut on right...seems either loose or too tight...swap castle nuts side to side..... that usually makes the nut adjustment and cotter pin fit easier.2 points

-

I borrowed some candles a few years back, the loaner tossed in a cat to make certain all was good! OUCH!2 points

-

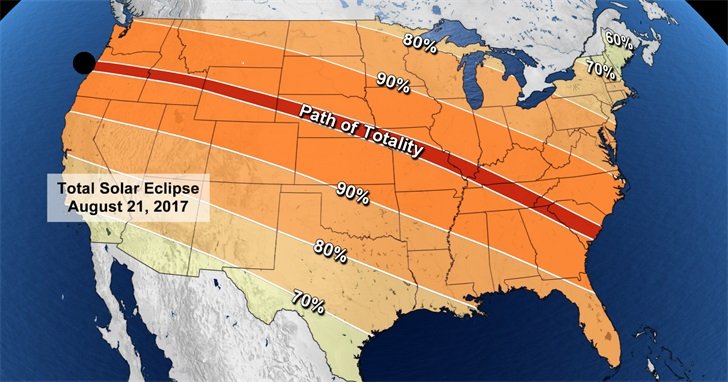

I can't believe the hubbub about this event. they say 100,000 visitors will flood the Portland area to view this 3min event. My sister rented out a room in her house to a family from Oklahoma and my niece has a visitor coming from France just to stay on her couch for this event. the news is hyping it up as possibly grid lock on the freeways, cellular tower overload, supermarkets packed, possible gasoline shortage, cash issues etc. kind of reminds me of the "y2k" funniest part to me, we haven't had any rain for over 50days and guess what they are calling for on the day of the eclipse........ yep, overcast and possibility of rain LOL, let me know if you want to rent a room in my house to see it get dark for 3min and rain (moderator's this was no way intended to be a siltation of services)1 point

-

My Nephew moved into his new house & did some exploring & found these nearby. He said the "dually" was last tagged in 2006. I'm wondering if they were both duallys & both outside wheels have been removed from one of them? I haven't seen these myself yet but will next time I visit my nephew but he did say both trucks looked complete.1 point

-

Champion spark plugs have given me more trouble than any other brand. For the Mopar flathead 6, I like Autolite 295.1 point

-

One of the guys in the testing department was a real know-it-all blowhard, quick to shift blame and point out others' mistakes...a real ray of sunshine. I noticed that he would leave his CB radio on his toolbox and asked him about that one day, was told to mind my own business...a few weeks later, we had a cold snap but some European aerial lifts needed to ship, so knucklehead was out there freezing his whutsitz off doing his job, but found the time to cuss at me for some minor problem, in front of several ppl, before he went back outside to test another unit. Once he went out the door, I pointed at the radio on his toolbox, asked the observers "how long should I hang him out to dry?" , they all immediately began laughing, so I told the small crowd that I would be back in 15 minutes... by that time, knucklehead was in the middle of articulation testing, it looked like it was about to start snowing, and I returned to hit the e-stop on the lower controls...this effectively stuck him 50 feet up in the below-freezing air, and after 5 minutes I went back out to pull the e-stop so he could let himself down...of course by then the hydraulics had gotten so cold that the ride down was excruciatingly slow, which allowed me plenty of time to vacate the premises while he shouted threatening curses in my direction, much to the amusement of his coworkers...I later found out that chickens-hit tried to get me written up for some sort of safety violation; the only problem was that he was making a complaint to the guy that I had turned in his radio and asked him to remind his test techs why they need their radios at all times, which by company rules was a terminating offense. From that point forward, we didn't have much of a problem...1 point

-

use what plymouthy adams said it is the correct product not what warrior dog used I was a auto glass tech for 24 years glass setting tape comes in diferent thickness and diferent compounds it is a press fit not adhesive that bonds the window carrier to the glass.1 point

-

I hear you........I would think the mate with all the 40/50's and vintage military models would have experience changing carbs to a different/modern model based on the cfm and air fuel ratio for selection of proper jetting.1 point

-

Pulled the front bumper to fill the license plate and optional bumper guard holes as well as fix some pretty deep gouges from over the years. Not to mention it had been painted with a brush at one time. Oven cleaner does wonders for that kinda stuff! Also added a bit of weld to the top mounting holes so I could use some pretty carriage bolts. I still need to do some final smoothing and sanding, but think they came out pretty good. It will look good for the show today and then I can work on it some more later when I have more time. BTW... I pulled my original hood emblem off to polish it and broke a stud. I am gonna send it out for repair. Unless somebody has the missing "8" for my V8 emblem they would be willing to part with... Then I would leave my new emblem on there.1 point

-

sorry but I read two different reports from post one to that of just now...just trying to establish if the carb got a fair shake....I have no suggestion for replacement...1 point

-

Reg,IMHO the old maxim that states 'If it ain't broken don't try to fix it" applies. If you look hard enough for something that is just a hair away from perfection,you will find it. This stuff is mechanical and complex. There will always be something somewhere that isn't at peak perfection,but still performs so well it isn't worth "fixing". MY opinion only,and worth every dime you paid for it.1 point

-

1 point

-

Heaters and all items considered "options" were dealer installed. Even through the early 50s.1 point

-

40 to 47 trucks. it is located directly above the speedometer. 39 trucks did not have this feature.1 point

-

1 point

-

gARY I HAVE A FACTORY HEATER IN MY 39 dESOTO. Most heater were installed by the dealer along with radio's and other accesories. One wire would be to a speperate heater control switch or knob that ran the blower motor. Contact me and i will send you some pictures of the factory MoPar heaters You need to stop by and look at my 39 becasue it is the sister car to your 39 Dodge I have a lot of factory dealer sheets and accessory sheets and dealer special instruction and dealer bulletin for 38 and 39. Rich Hartung desoto1939@aol.com1 point

-

you should snug up the nut then spin the wheel a couple of turns to force out some excess grease from the bearings. Then check to make sure there is no wobble in the bearing. If you have to move the castle nut to allow the cotter pin to fit, you should loosen the castle nut a fraction of a turn rather than force it to tighten.1 point

-

Rich, I am sorry this happened. Please update us on the repaired Tool. Every, yes every time in my life that I lent tools out, except once - maybe - I had to finally go ask for them back. Sometimes never to even get them back. This brings to mind, as well as the Shakespeare saying: "No good deed goes unpunished". Well here's hoping you get it fixed and feel better about the whole thing after all. You are a good fellow to have endured for so long, and I hope one goonie bird doesn't ruin your outlook on life or our group here. Good Luck. Tom1 point

-

Frank... Wow that is super cool! I ran into a guy delivering Drive magazine the other day in front of Napa. He asked if he could take photos of my truck. Little did I know they would be posted up somewhere.1 point

-

This tool was made for the mechanics back in the days when you rebuilt the W/cylinders on the car. It's not too easy to pop all the pistons out so this tool idea came up. Back when these cars we like were new the owners and mechanics didn't spent days doing /painting the brakes. They had to get em done in less than a day and I suppose this tool speeded things up a bit to make more profit and make it easier for the mechanic to get his job done faster. I use a pair of snap ring pliers to remove unstuck pistons...air or grease to push out stuck pistons. I now always re-sleeve now days.---even new replacement cylinders foe the elimination of corrosion W/DOT 3 or 4 and Silicone 5 too.1 point

-

I believe 3.5 to 5 .5 psi is in the ball park. There is a test for volume also. Remove the line from the float bowl, direct the stream into a container, a 20 ounce plastic beverage bottle will work. With the coil wire pulled from the dist, have an assistant turn the engine over with the starter. Count the pump pulses while gas goes into the container. 12 to 15 pulses should yield 6 to 8 ounces in the bottle. Any less indicates a blockage from the tank to the pump. The flex hose between the frame cross member and the pump can be the culprit as it may look fine but may be collapsing under suction and pinching off flow. If after testing the car won't start, reattach the coil wire in the distributer....1 point

-

Now my basic beliefs are shattered. Maybe there is more than one way to install an adjustment arm. Maybe the slot is supposed to be at the bottom, and behind the generator boss. Nah, my way has the advantage that I was able to seal a stud and nut at the block, rather than having to loosen a bolt to free the arm, and the arm is free to pivot without loosening a bolt. To quote my mother-in-law: "' To each his own," said the lady as she kissed the cow."1 point

-

1 point

-

A tool for installing wheel cylinder pistons. It holds the seal collapsed while the bar pushes the piston and seal into the wheel cylinder bore1 point

-

1 point

-

I love my uncles philosophy, I aint borrowing no damn tools, be my luck I would break it, then have to buy them a new one, I still wont have the tool. No sir, I will just buy my own!1 point

-

1 point

-

As a emergency repair I installed a Weber 32/36 on my -47 Dodge. The carb I had in my garage, have used it on a Volvo 240 B230 engine before. The reason for the swap: the old Stromberg carb on the Dodge is just worn out. With the weber the car starts easy, idles ok but got high fuel consumption and the car des not pull very good. I guess it comes down to the jets. The question: Does anybody here have experience with what jet sizes works good with a single 32/36 on the 230 cui?1 point

-

1 point

-

There is a spec for how far down they sit below the deck....I made a depth gauge so the guides could be set to (in my case) .875" below the deck. Another caution....you have to swing a hammer pretty dam hard to move the guides far enough down to remove them. I was using a tool to set concrete anchors and all was well till I missed and smashed an index finger with my bfh. Fractured the finger, this was last May, and I know it'll never be right. That's when I went on the hunt for a valve guide driver to use with my air hammer. This worked great with the exception of the install. One of the 12 guides was so tight, the air hammer wouldn't move it. I had to use the driver to hammer it home with the bfh. This tool is long enough and tough enough to be used like this, so it's kind of like getting two tools for one.1 point