All Activity

- Today

-

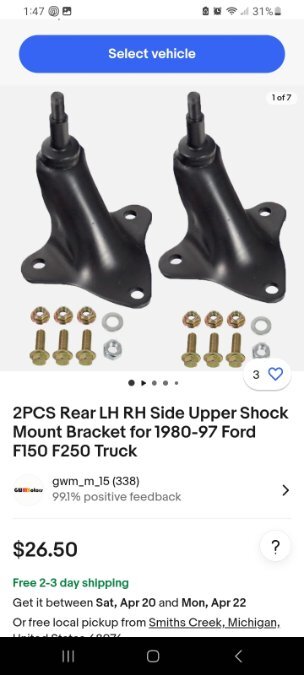

andyd started following Potential cheap shock relocation Mount option

-

Interesting question.......those mount on a flat surface which may or may not work where the chassis upper shock spot is on the 1940-48 mopars, also the lower mopar mount is basically pointing to the rear of the car....these mounts when attached to the chassis have the "pin" pointing more or less at 90 degrees to the frame........but usually the upper & lower shock eyes can be turned at 90 degrees to each other...........I'm curious whether they may work.........andyd

- 1 reply

-

- 1

-

-

1936 Ford Other Pickups On Ebay https://www.ebay.com/itm/116128145840?

-

Dan Capeci started following Potential cheap shock relocation Mount option

-

I'm gathering parts for when I start working on the front end of my 48 Business Coupe, and was looking at the F1 shock mounts and came across these. Anybody have any thoughts on them or why they wouldn't work? For the price it might be worth trying out and I'm seriously considering it.

-

Nice... 🙄

-

Quick update so I'm getting back the clutch tourque shaft from the machinist. The clutch adjust rod has been straightened it did not have a brnd from the factory. I'm not using and olite bearing for future retrace since that's the case whir lithium grease on the inputs shaft. Last but not least there was no bushing in the crank when I took it apart I contacted the original owner the car was driving for 6 years with no pilot bushing and without making a whole lot of noise.weird honestly seeing that I really don't feel that bushing really is to critical or something surely would have came apart.thank you everyone for all the support I'm getting this car registered next week so need these parts to hurry up so I can get to the bottom of this

-

VINTAGEPIC: saw this Dodge on the FB

-

How Many Pilot House Trucks Have Survived?

JBNeal replied to Bradley S.'s topic in Mopar Flathead Truck Forum

SURVIVOR: saw this Dodge between Lake Graham and Newcastle -

The last time I took a 3-speed apart, every single part (including the iron cast housing), except for the counter shaft, was no longer in spec. That input shaft has at least 3 places that needs to be checked: the tip, the "hole" for the main shaft on the opposite end, and the main bearing seat. If you really want to do this right, you would also probably measure the teeth wear and the shaft's end play (when assembled). These operations are performed with 3-4 different micrometers and a dial indicator. I don't know what the specs for this transmission are (they are not listed in the simple repair manual) but they do exist.

-

Reminds me of a story about old Uncle Cletus. ..... The girls in town would claim he needs to go home and clean that input shaft up .... What the heck do they know? IMHO, the splines on this shaft look really nice with sharp edges on the teeth ..... little wear on the front of the shaft. To me it is like the first 1" of the shaft that inserts into the pilot shaft bushing ..... I would want that really smooth . I would use some emery cloth to smooth it up .... same time i would not want to remove any material and make it smaller ...... I would put some grease on the end of the shaft and shove it into the bearing. I doubt I would ever have a issue with it years down the road. The 2nd photo you showed, looks a little awkward ..... It may work also. If needed.. The very front 1" of the shaft sits in the bearing. Just saying the very first 1" sits in the bushing. The clutch disk is splined and rides on the splines of the input shaft. The pressure plate is behind the clutch disk, and the throw out bearing is behind the pressure plate ..... Nothing matters between the the splines and the front of shaft .... Only that the front 1" is smooth for the pilot shaft bearing. Thats why I say the 2nd photo is awkward .... It looks good 1" in front but then has a groove cut into it ...... That area is simply not in use .... nobody cares .... the factory cut a groove in it for some reason ..... Just pick the best one to use. You will be fine.

-

-

Yeah I’m not gonna try that. I like the idea of having a backup pump. I didn’t think the tee idea would work just checking.

-

Both of those input shafts look like scrap metal. The seat for the bearing/bushing, at the tip, should probably be checked with a micrometer 🙄 The next time you have everything back together, do a quick test before you attempt to mess with anything else: when the clutch pedal is released, the clutch disc (partially visible from the bottom) should be tight between the flywheel and the pressure plate. When the clutch pedal is pressed down, you should be able to spin the clutch disk with a thin screwdriver. If it ain't working this way, do not attempt to start the car, etc., it will not do any good, at this point. Also, this clutch video might have some useful info.

-

I have only installed a 2 piece flat windshield once, so I cant give specific advice, but I recall that multiple friends are a big asset to the task. Some pizza, cigars, beer, whatever you have to do to get some extra hands will be well worth it. Go slow and be patient, you can make it happen. Good luck!

- Yesterday

-

Possible problem with a bypass around the electric pump. with out a check valve When you power up the electric pump it will take the path of least resistance and flow right back in to the pickup line.

-

Did you guys already watch the instructions?

-

Unfortunately I don’t have a gauge for checking fuel pressure yet. I guess that’s the next investment. For now I’m insulating the line from the pump to the carb. If that doesn’t work I’ll bypass the electric pump and try that. I just checked the line and found no leaks so that’s good.

-

moose started following My 54 Belvedere, and windshield questions

-

I haven't posted in a while, but there is at least one other thread about this car. I have owned it since December 1989. It is my first car, got it when I was 17. Two years ago I had a fire under the hood. Not big enough to cause a lot of problems, but enough that I decided it was finally time to do a mostly full "restoration." I disassembled everything, stripped most of it, then took it to a good paint shop. Picked it up last December, and now have it mostly put back together. I have driven it around the block, and hoped to drive to my local glass shop to have the windshield and rear window installed professionally. When I talked to him about doing the job, he seemed enthusiastic, and knowledgeable. I dropped off all the parts(windshields, weatherstripping, and stainless) yesterday waiting for a call telling me to bring the car. Went by the shop this morning and he told me he wasn't sure how to do it and afraid to try. I've got the manual and instructions, and have read everything about it, and now have the weatherstrip installed on each of the glasses. Question for anyone who has done this on a 53-54 car. Do I need to put the stainless on before I rope the windshield(or rear window) per the manual? I've built a stand to hold the window vertical, which makes it a bit easier, but it's still quite difficult to get the stainless in place. How hard is it to install the stainless after the windows are in place? Thanks for any info.

-

lafemme56 joined the community

-

I admit to going to tractor supply often also. My jack stands, floor jacks .... Boots, bolts, the paint on my truck, plants and garden supplies. I think of it as a big convenience store that sells things I like .... I recently went there to look at oil. I buy my oil from walmart usually, I need Dexron III ATF for the wife car. Walmart did not have it. So I looked at TSC ... they did not have it either. I will order from Amazon now. What I did see was some pretty incredibly high prices for oil at TSC. Oil at walmart was $20-$40 for 5 quarts, $40-$65 at tsc for same stuff. I like tsc but not for oil. .... And the shelf's were pretty bare.

-

ANSWERED 48 b1c door seal installation

mikes48 replied to mikes48's topic in Mopar Flathead Truck Forum

Thank you -

Forgot to add that you should take a reading of each pump. The electric with the car not running and then the mechanical running. When you take the reading with it running the mechanical pump pressure might not change as it will only check the pressure of the pump not the volume. If you take a reading behind the mechanical pump, it may read vacuum and that may change when you take the electric pump out of the circuit. This may involve installing the gauge a couple of times in two different areas. Joe Lee

-

b923 joined the community

-

Did you install a fuel filter before the electric fuel pump? I believe the electrics are more prone to fouling than a mechanical due to the motor being fuel cooled. I can't think of a reason the warmer temp would be an issue though, unless the switch from winter to summer blend fuel has something to do with it. You might want to take a fuel pressure reading at the carb then run a bypass line around the electric pump, take another reading and see if the pump is causing a problem. That's all I can think of right now. Some others might chime in with something else hopefully. Joe Lee

-

SteveTanderson joined the community

-

The best I have found so far is Wizards metal polish. I've tried Mothers and Never Dull and the Wizards works far better than either of the other two.

-

Will it do after the truck has been started? Does the engine need to be brought up to temp or just started?

-

Joe, my mechanical pump is new and didn’t solve the problem. The weird thing is that the problem is temperature sensitive and my engine doesn’t run hot (steady 160 degrees). My tank and lines are new. I’m going to try bypassing the electric pump to see if that makes any difference. I never had this issue before I added the electric pump but it didn’t start doing this immediately after so I’m stumped.

-

That's a reasonable thought except the existing 218 bolts are snug in the rod and cap holes. I absolutely cannot put a standard 3/8-24 rod bolt into the 218 rod or cap. ( I could problably smash them in and destroy the threads in the process. ) The 218 hole diameter is too small for a 3/8-24 bolt. Attached is a pic of the two bolts. Best harbor freight caliper dimension of hole in Pontiac rod cap with 3/8 bolt is .384. Best harbor freight caliper dimension of hole in Dodge 218 rod cap is .370. Doesn't make any sense.